Structure for cooling

a technology of structure and water retention, applied in the field of structures having water retention members, can solve the problems of no cooling effect, no cooling effect, and uncontrolled cooling efficiency, and achieve the effect of controlling cooling efficiency and eliminating or minimizing fungal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

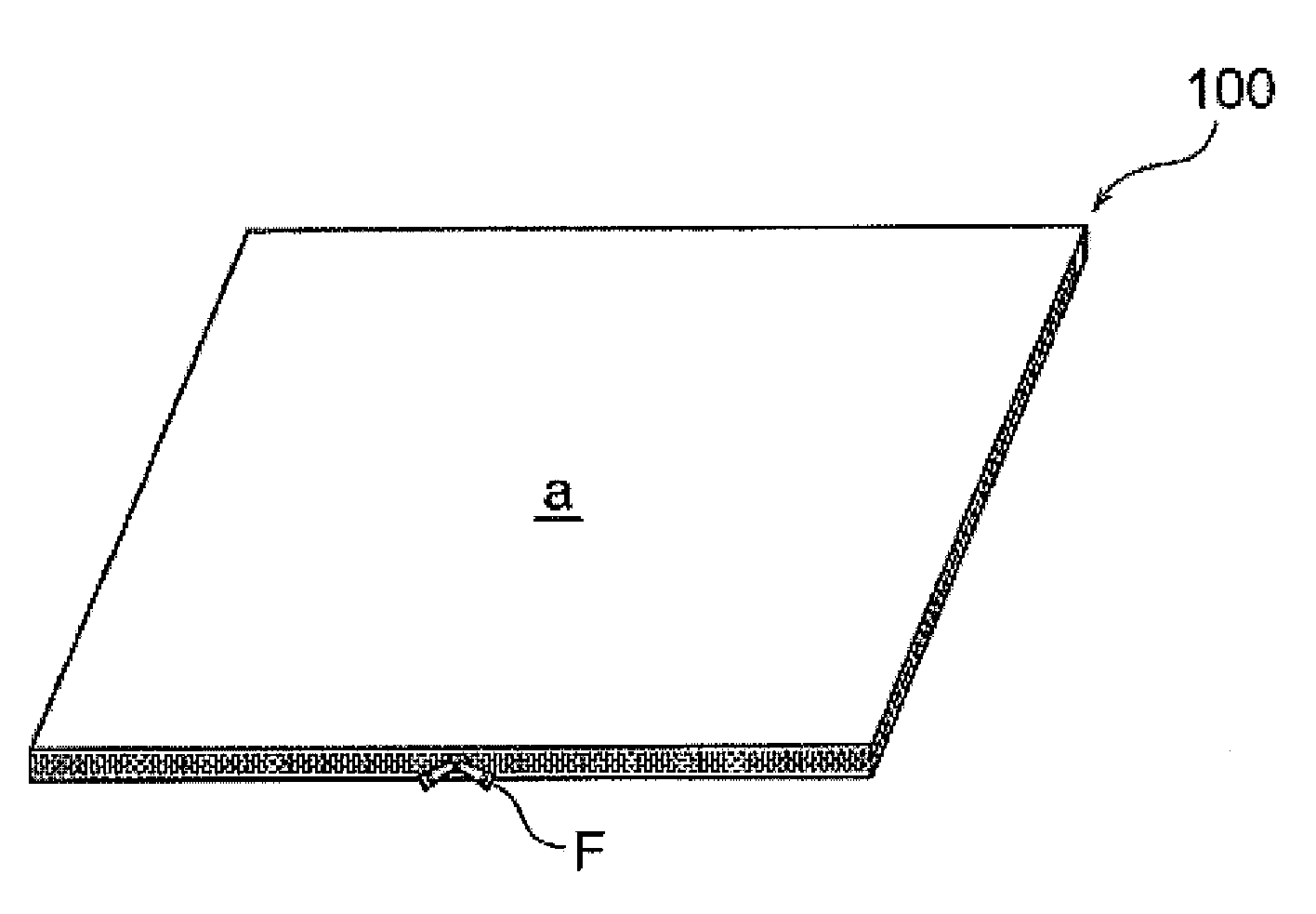

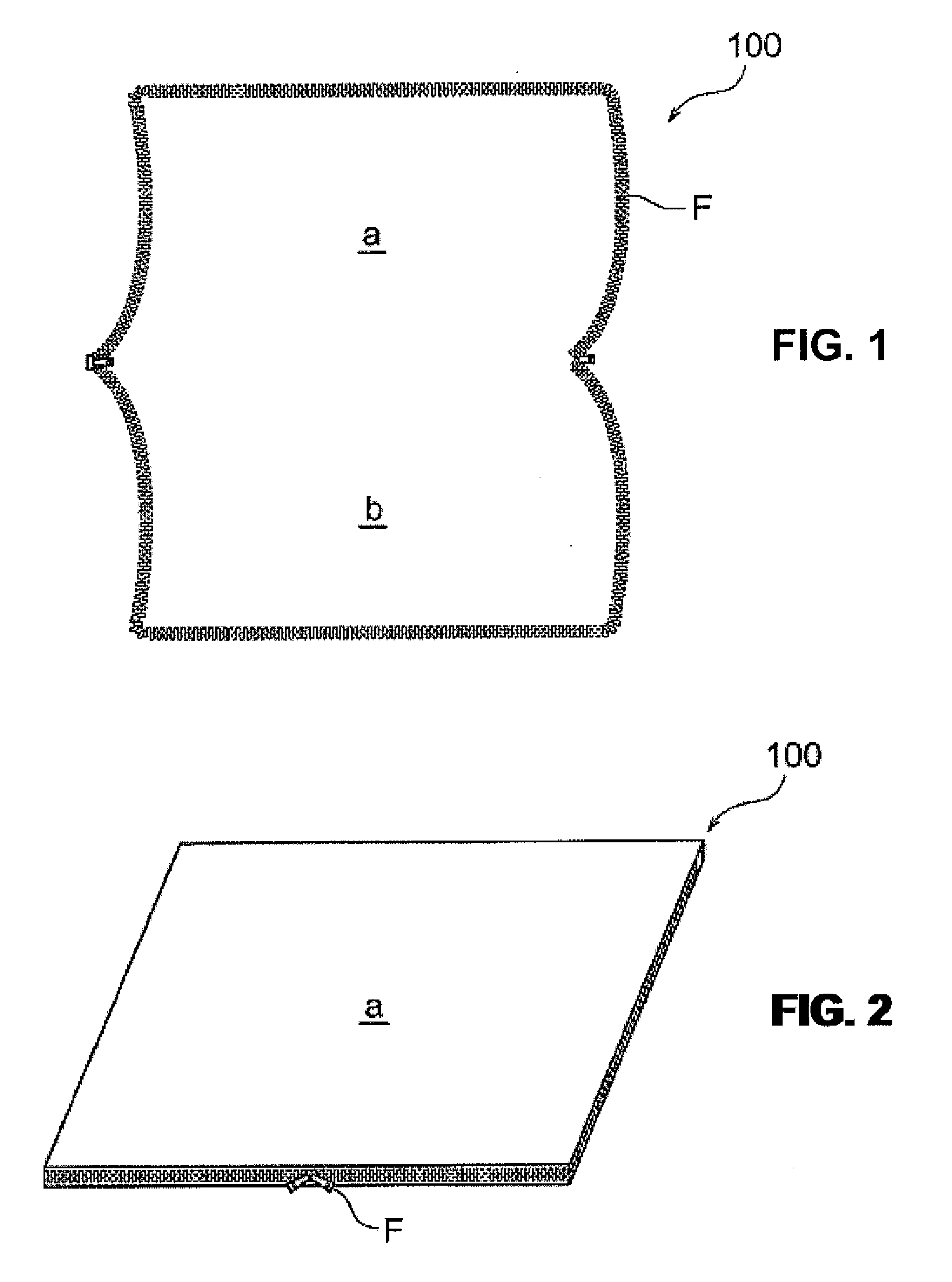

Image

Examples

example 1

(1) Preparation of Pads

[0120]The pads shown in FIG. 9 may be prepared, for example, by using the following materials:

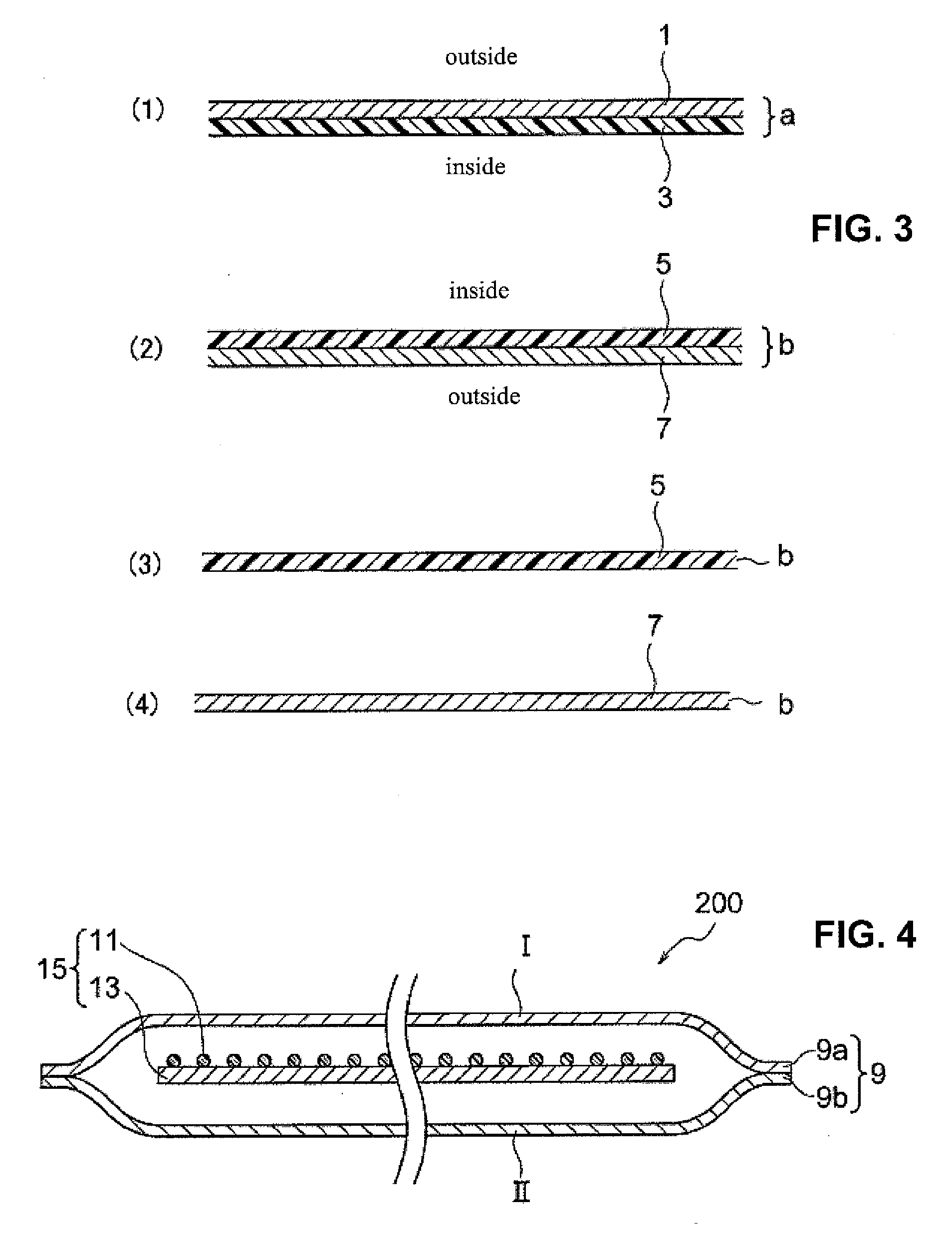

[0121]A. Materials Used for Each Layer[0122]A-1. Fibrous layers 1 and 7 of a cover 100: a board made of polyester (65%) and cotton (35%); yarn finenesses of 45 counts×45 counts with density of 100×70.[0123]A-2. Air-permeable sheet layer 3 of a cover 100: porous polyethylene film with thickness of 50 μm.[0124]A-3. Air-impermeable sheet layer 5 of a cover 100: polyethylene film; thickness of 50 μm.[0125]A-4. Nonwoven fabric 9x of a bag P of a water-retentive member 700; a lid portion: spun-bonded nonwoven fabric made of a polyester with thickness of 40 g / m2.[0126]A-5. Nonwoven fabric 9y of a bag P of a water-retentive member 700; a bottom portion and side portions: spun-bonded nonwoven fabric made of a polypropylene with thickness of 40 g / m2.[0127]A-6. Air-impermeable sheet layer 19 of a bag P of a water-retentive member 700: polyethylene film with thickness of 40 μm.[0...

example 2

(1) Preparation of Pads

[0141]Similar to Example 1, three kinds of pads are prepared having a size of 100 cm×200 cm. For the air-permeable side of the cover, composite materials a having moisture-permeability of about 1,000 g / m2·24 hours, about 1,200 g / m2·24 hours, and about 1,500 g / m2·24 hours by the Lyssy method are used. The amount of the water poured into the pads is 7 kg per pad (i.e., 3.5 kg / m2 of the water-retentive member).

(2) Organoleptic Test

[0142]A futon (which is like a mattress) is positioned inside a room, in which the temperature is set at 30 degrees Celsius. The pad is laid on the futon and covered with a sheet made of a cotton. As a control, a futon without the pad is prepared.

[0143]The surface temperatures on the sheet are determined by using a surface thermometer. Each panelist lies on the sheet and judged at appropriate time intervals whether he(she) feels cool or warm at neck, shoulders, loin, hip, legs / feet, and arms. The results from these tests are shown in FI...

example 3

(1) Preparation of Pads Containing Antifungal Agent

[0145]One pad is prepared in the same manner as described in Example 1, except that the cover 100 has a size of 95 cm×185 cm. The water-retentive member 700 has a size of 90 cm×180 cm containing an antifungal agent. The air-permeable side of the cover has a moisture-permeability of about 1,000 g / m2·24 hours.

(2) Preparation of Liquid Containing an Antifungal Agent and Binder

[0146]Table 1 shows the formulation of a solution containing an antifungal agent. The solution is prepared by mixing the raw materials.

TABLE 1AmountsRaw Materials(% by weight)Amorden NBP8 (Triazole Derivative from Yamato2Chemical Industrial Co., Ltd.)Aqueous Binder of Vinyl Acetate Derivative1Water97Total100

(3) Adhesion of Antifungal Agent

[0147]From about 1 meter above the nonwoven fabric 9x of the bag P, the solution shown in Table 1 is uniformly sprayed on the water-retentive member 700. The amount of the solution used is about 500 g. Namely, to the water-retent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Impermeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com