System and Method for Leaching a Metal from a Base Mineral Rock

a technology of metal leaching and mineral rock, which is applied in the direction of material recovery, process efficiency improvement, etc., can solve the problem that the amount of time required by current technology takes an average of 12 hours, and achieve the effect of enhancing the aeration effect of the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

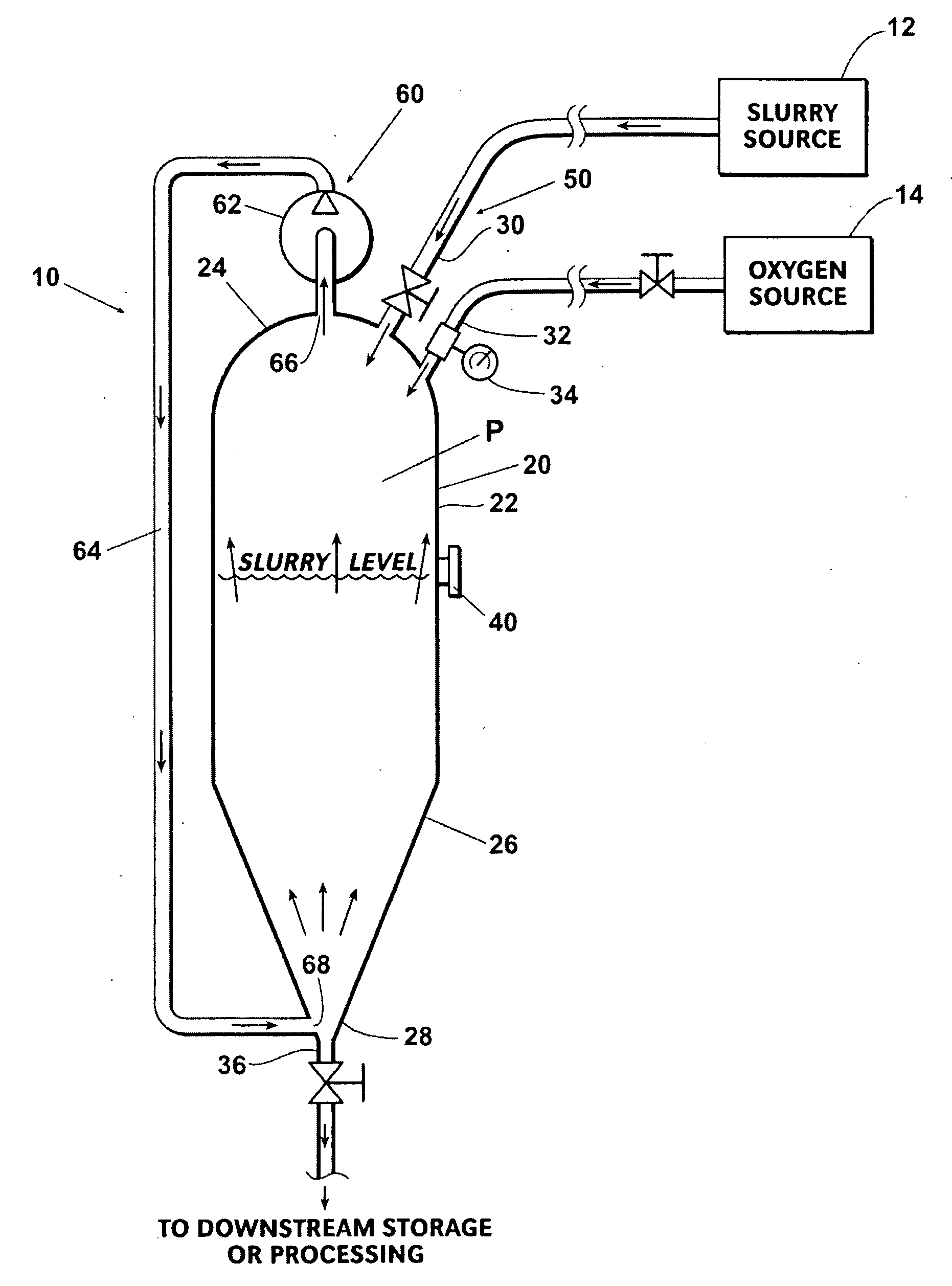

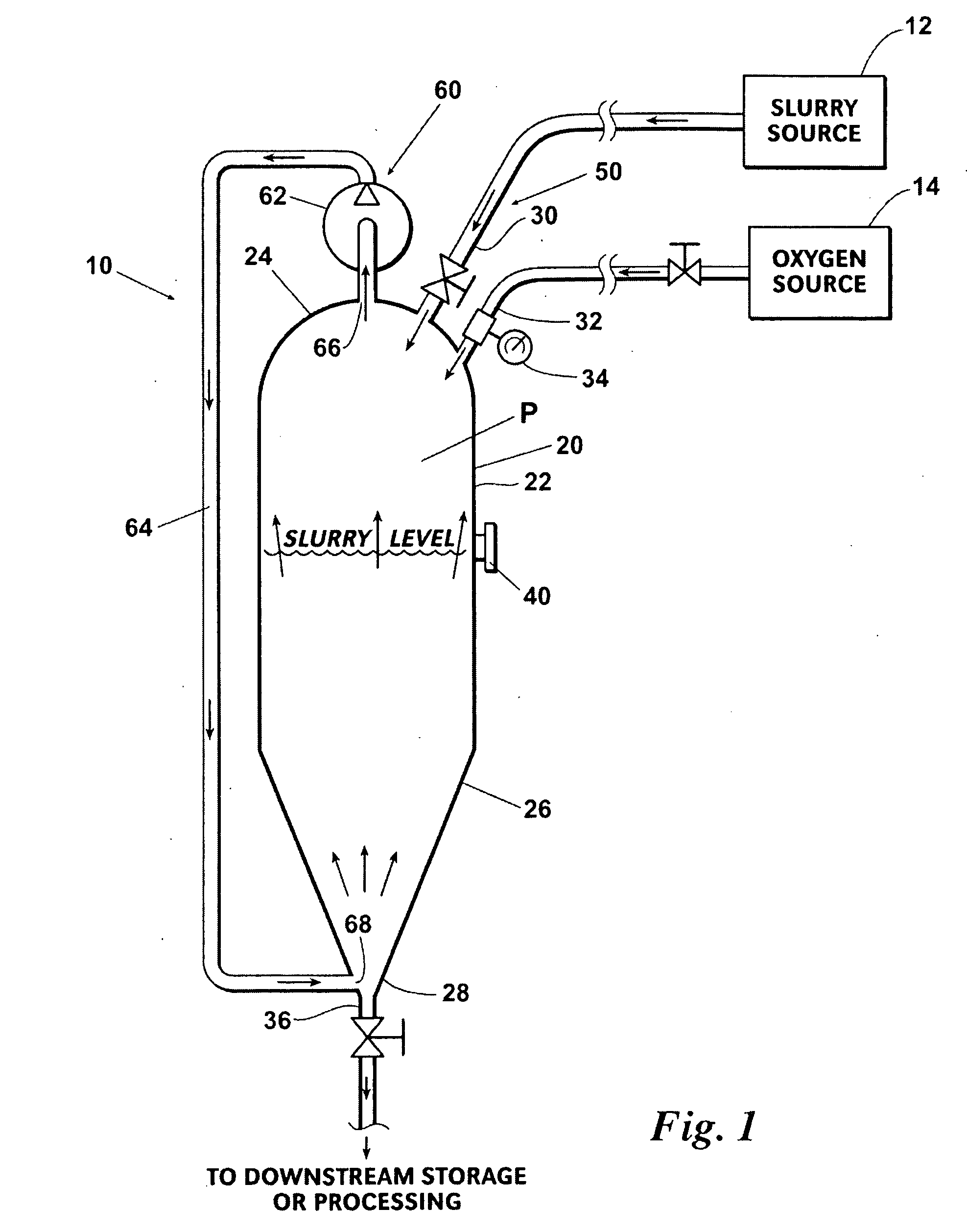

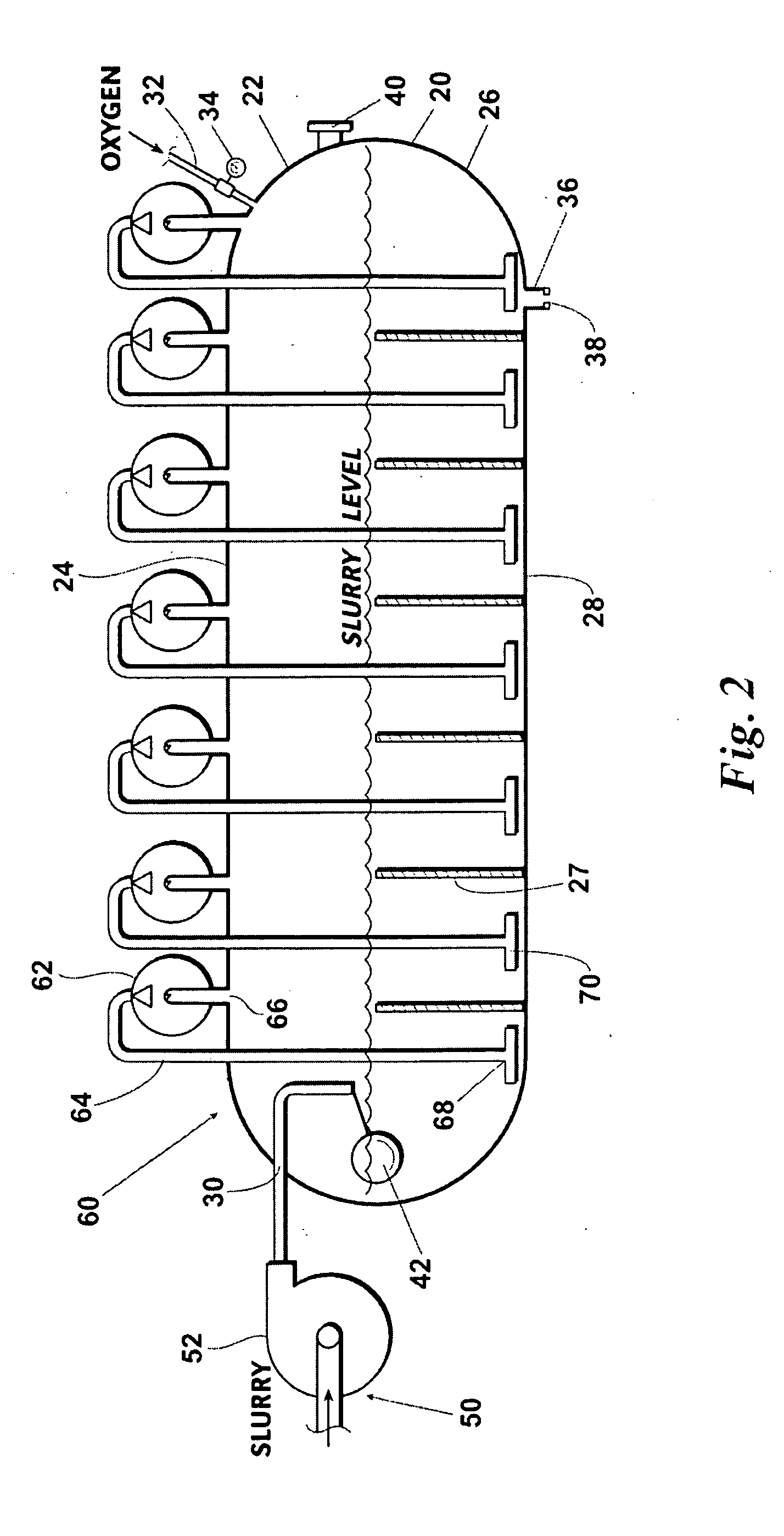

[0010]Preferred embodiments will now be described in reference to the drawings and the following element numbers:

10System for leaching metal12Slurry source / tank14Oxygen source20Reactor22Upper portion24Top end26Lower portion27Baffles28Bottom end30Slurry inlet32Oxygen inlet34Pressure gauge36Outlet38Discharge nozzle40Sight glass42Level float50Piping arrangement52Slurry pump60Agitator62Blower or compressor64Re-circulating piping66Inlet end68Outlet end70Jet

[0011]A system and method for leaching a metal from a base mineral rock employs an attacking agent mixed with the ground base mineral rock and oxygen that re-circulates through and agitates this slurry mix while the slurry is under a pressure above ambient pressure. Referring now to FIG. 1, a system 10 adapted for batch processing includes a reactor 20, a piping arrangement 50 and an agitator 60. Reactor 20 is preferably a vertical pressure vessel having a tubular upper portion 22 with top end 24 and a conical-shaped lower portion 26 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com