Skylight with curb design

a technology of curbs and skylights, applied in skylights/domes, roofs, constructions, etc., can solve the problems of limited structural integrity, difficult transportation and use on construction sites, and difficult assembly on si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

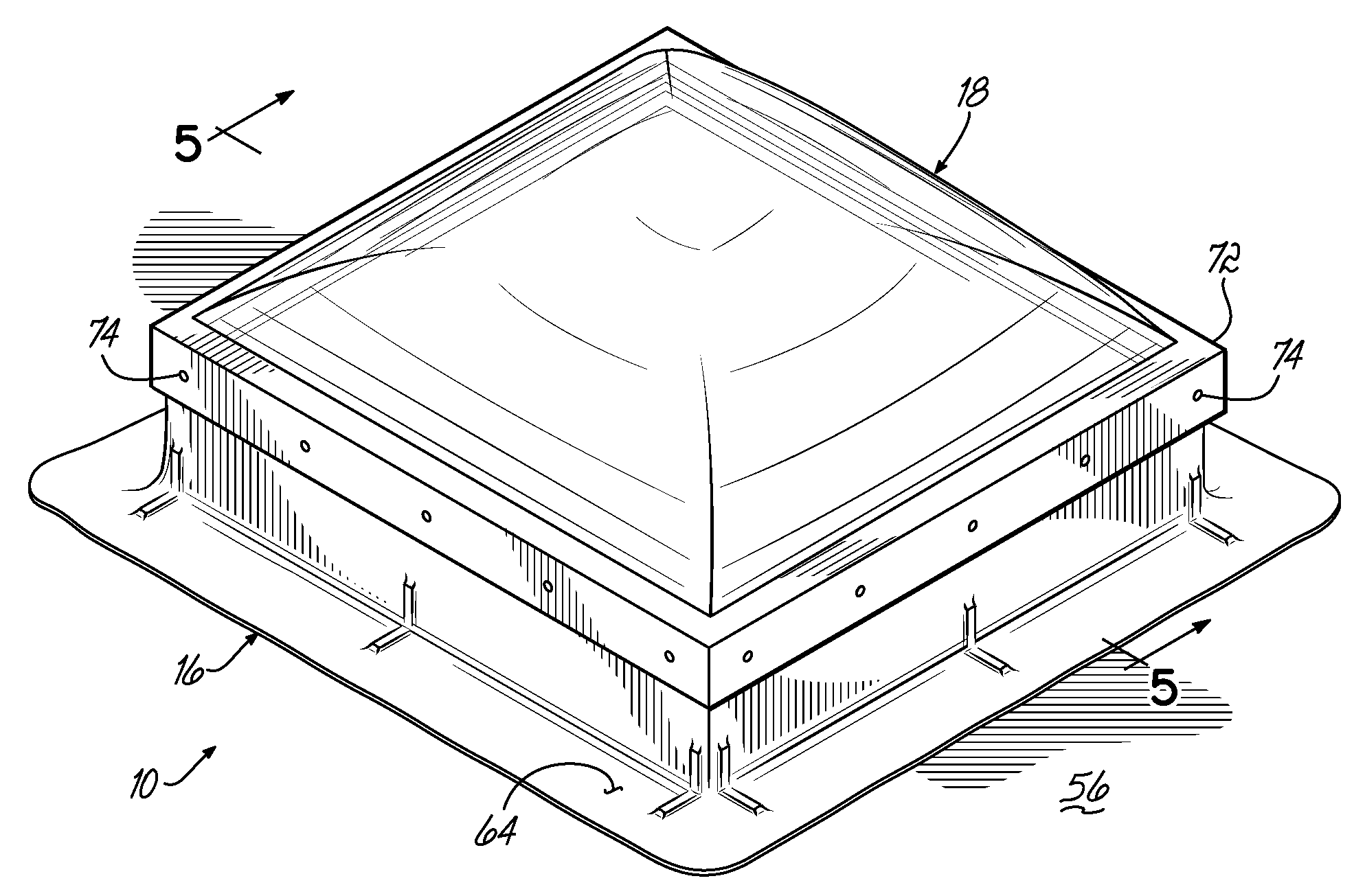

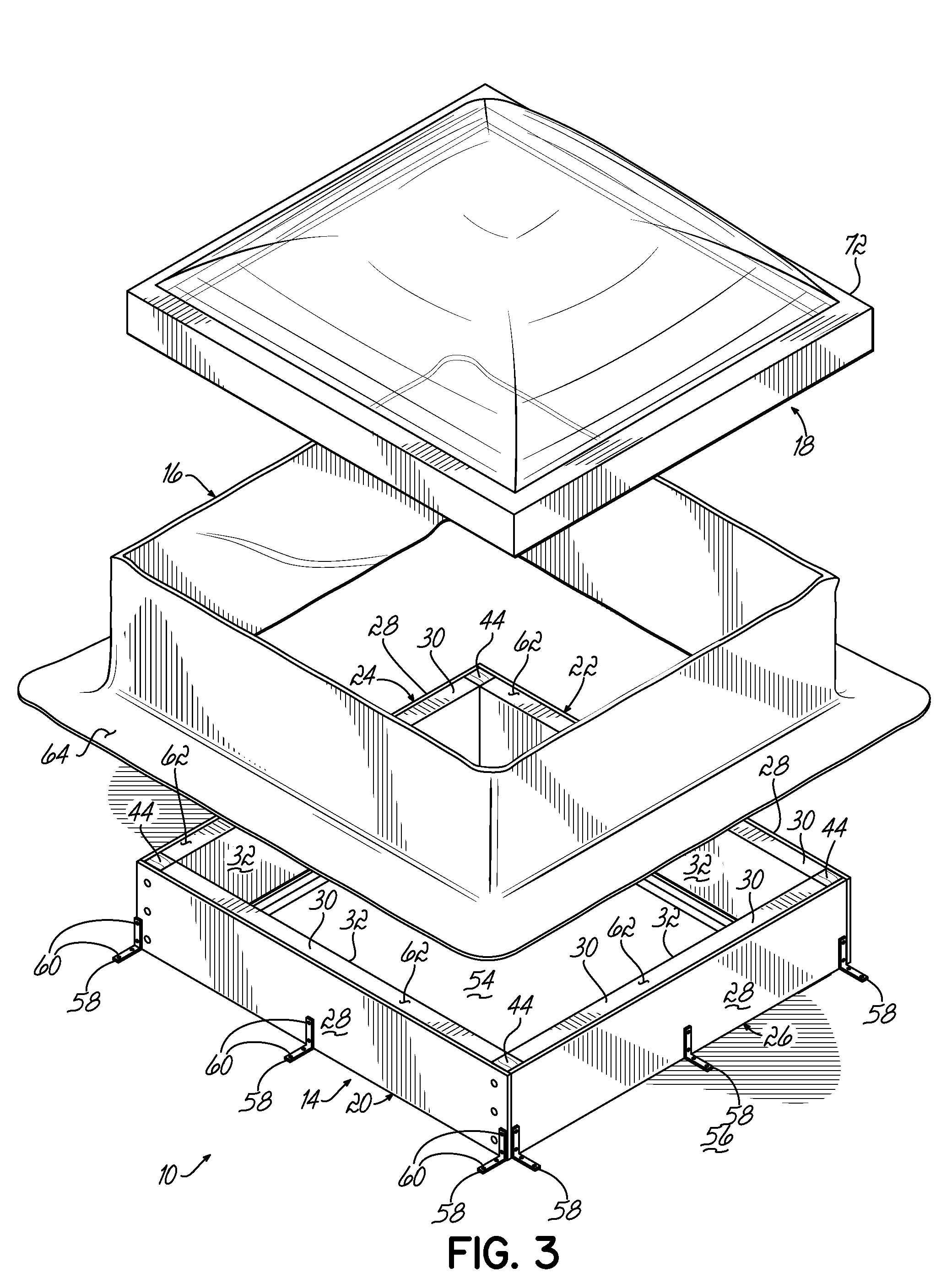

[0012]As shown in FIG. 4, a skylight assembly 10 located on roof surface 12 includes a rectangular curb 14 surrounded by flashing 16 with a skylight 18 resting above the flashing and the curb.

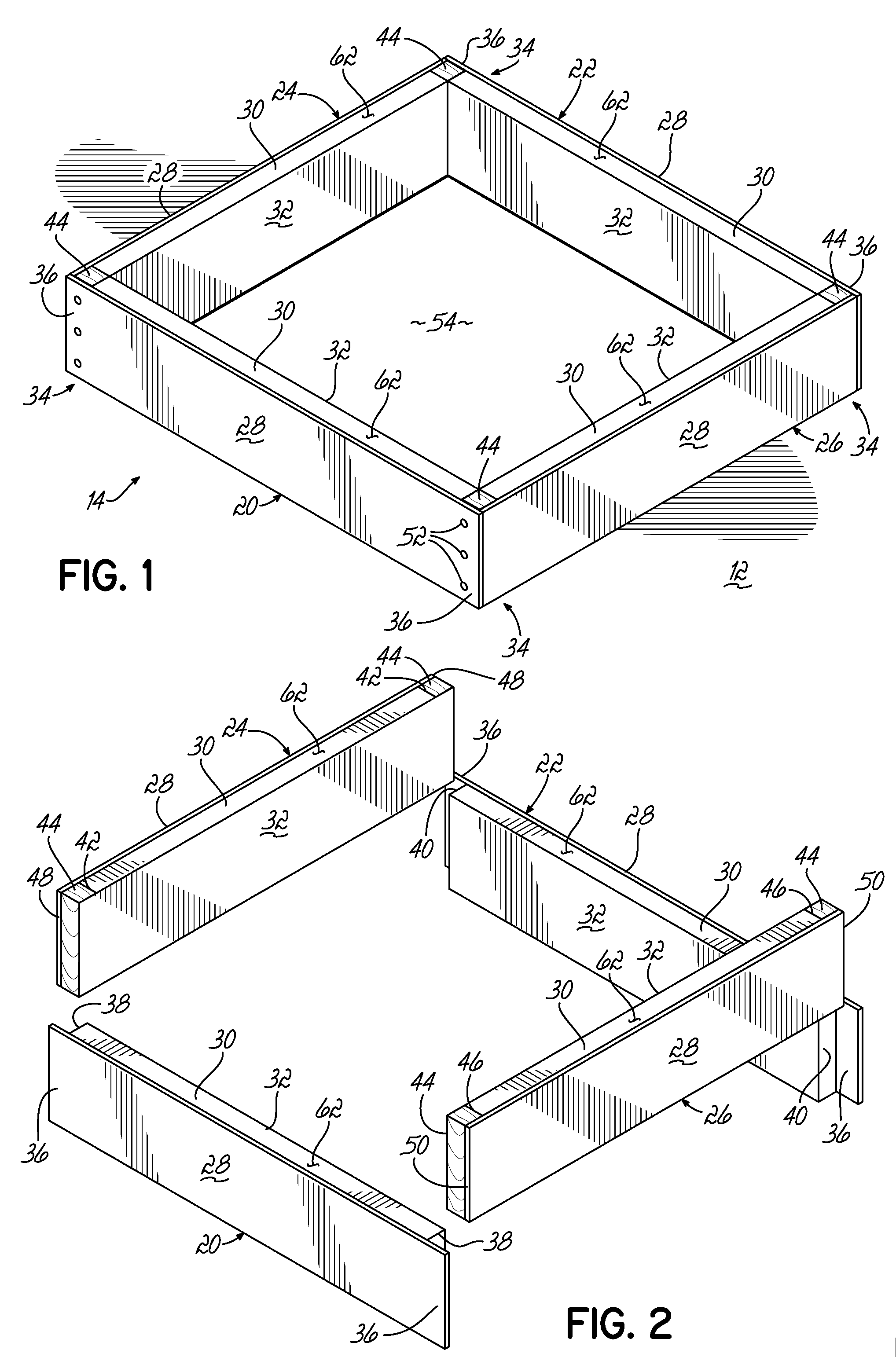

[0013]The curb 14 is formed from structural insulated panels or SIPs 20, 22, 24 and 26. The SIPs each include an outer portion or layer 28 which is designed to receive and hold a fastener, a central foam portion or layer 30 and an inner finished portion or layer 32. The length of the SIPs is determined by the size of the skylight while the height can be about 9 inches or more.

[0014]The outer portion 28 can be formed from any material that will receive and hold a fastener. Typically, it will be a wood based material such as plywood, particle board or OSB or metal. In particular, OSB having a thickness of from about ¼ inch to about ¾ inch can be used, and, in particular, OSB having a thickness of about ½ inch to 7 / 16 inch provides adequate structural integrity. To provide fire retardance a layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com