Use of pure carbon dioxide as an inerting and flow medium in powder injection systems for use in pulverized coal gasification under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

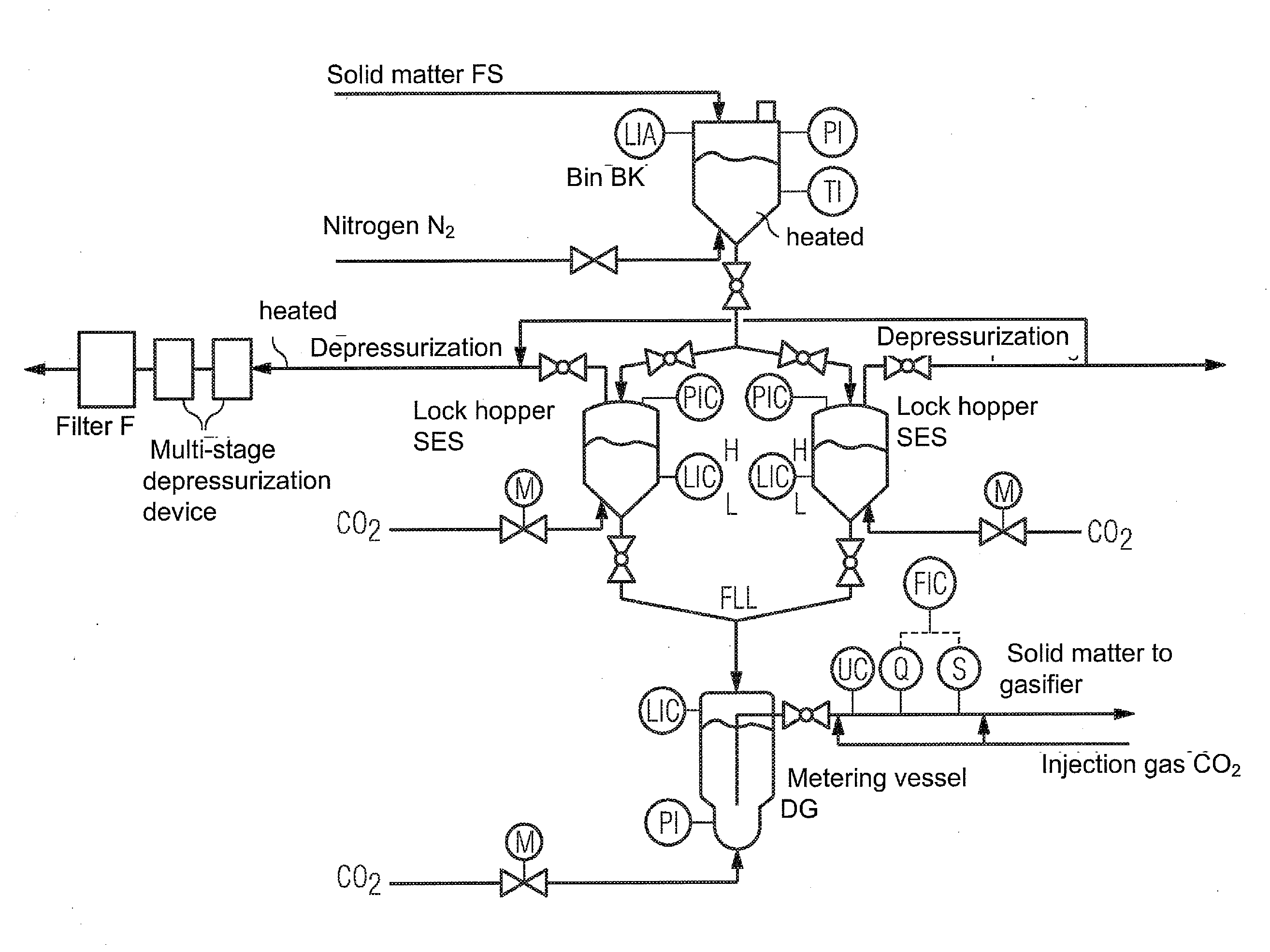

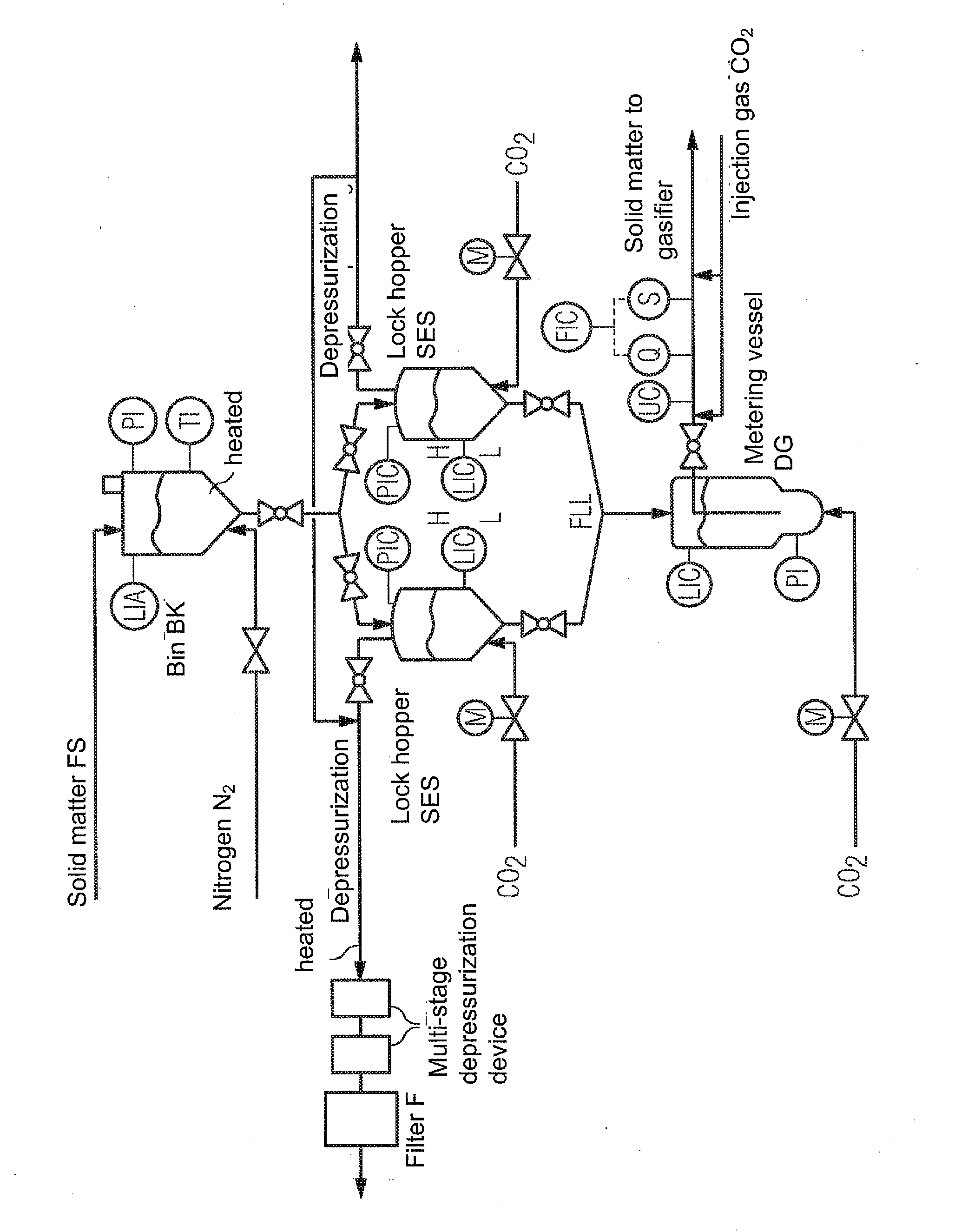

[0010]Heated nitrogen N2 can be fed as an inerting and disaggregating medium to a bin BK for storing solid matter FS such as pulverized coal, which bin is at ambient pressure and can be heated. The solid matter can be fed via a conveying device to a feed lock hopper SES which is at a high operating pressure of e.g. 40 bar. Carbon dioxide CO2 can be supplied to the feed lock hopper as an inerting and conveying medium at a temperature above the threshold to the two-phase region at high operating pressure. In the upper region of the feed lock hopper the depressurization gas is drawn off, expanded to ambient pressure via a multi-stage depressurization device mEV and de-dusted in a downstream filter F at ambient pressure. The solid matter is transferred by gravity flow from the feed lock hoppers to the metering vessel DG via an adequately dimensioned downcomer. Two to four lock hoppers are used for each particulate feed system.

[0011]Carbon dioxide is used as a fluidizing gas. A partial f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com