Brightness enhancement film and backlight module

a technology of enhancement film and backlight module, which is applied in the direction of instruments, waveguides, lighting and heating apparatus, etc., can solve the problems of reducing the accumulation of light, unable to diffuse light evenly on the display, and not having the function of accumulating light, so as to avoid moire effect and improve brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

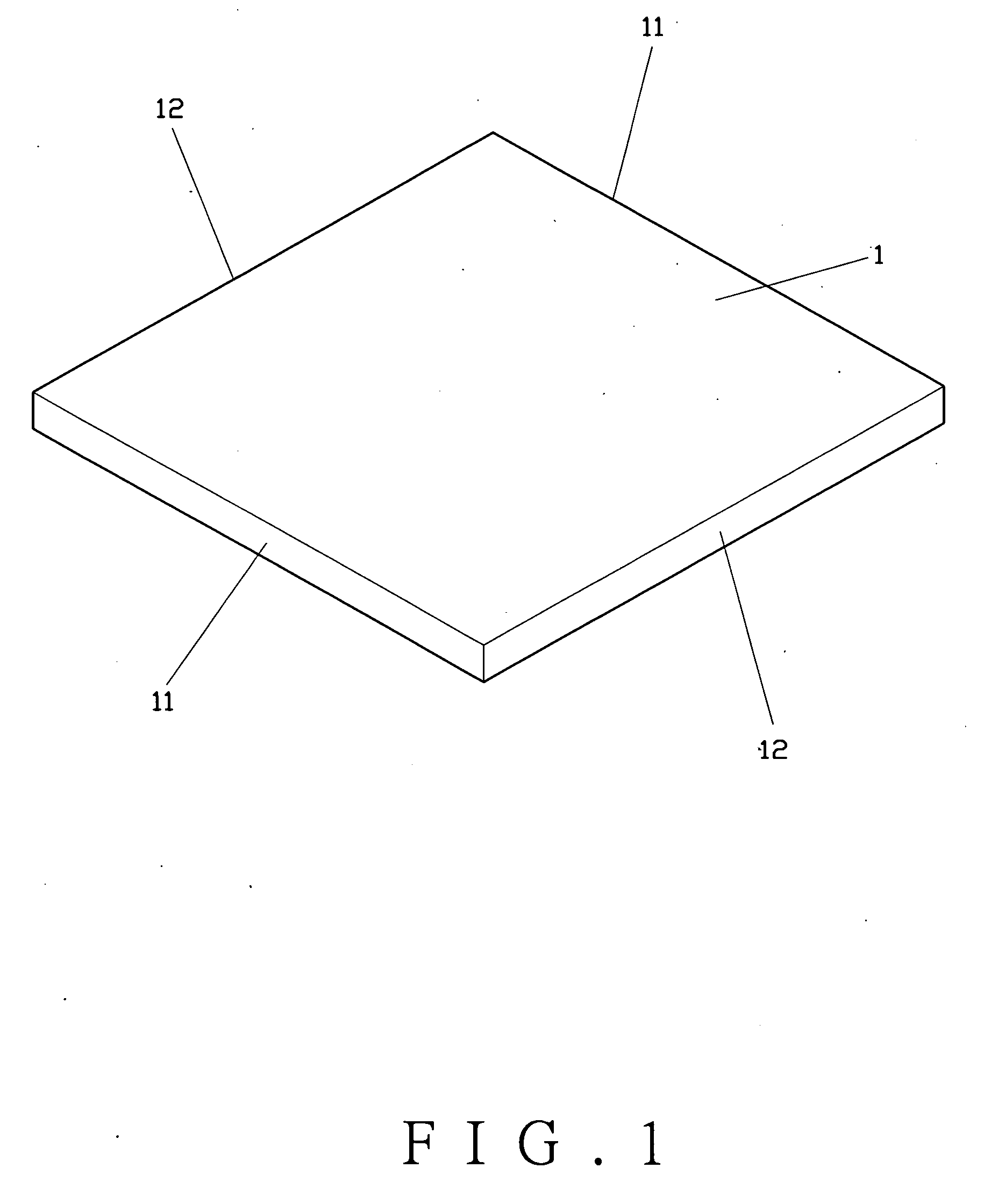

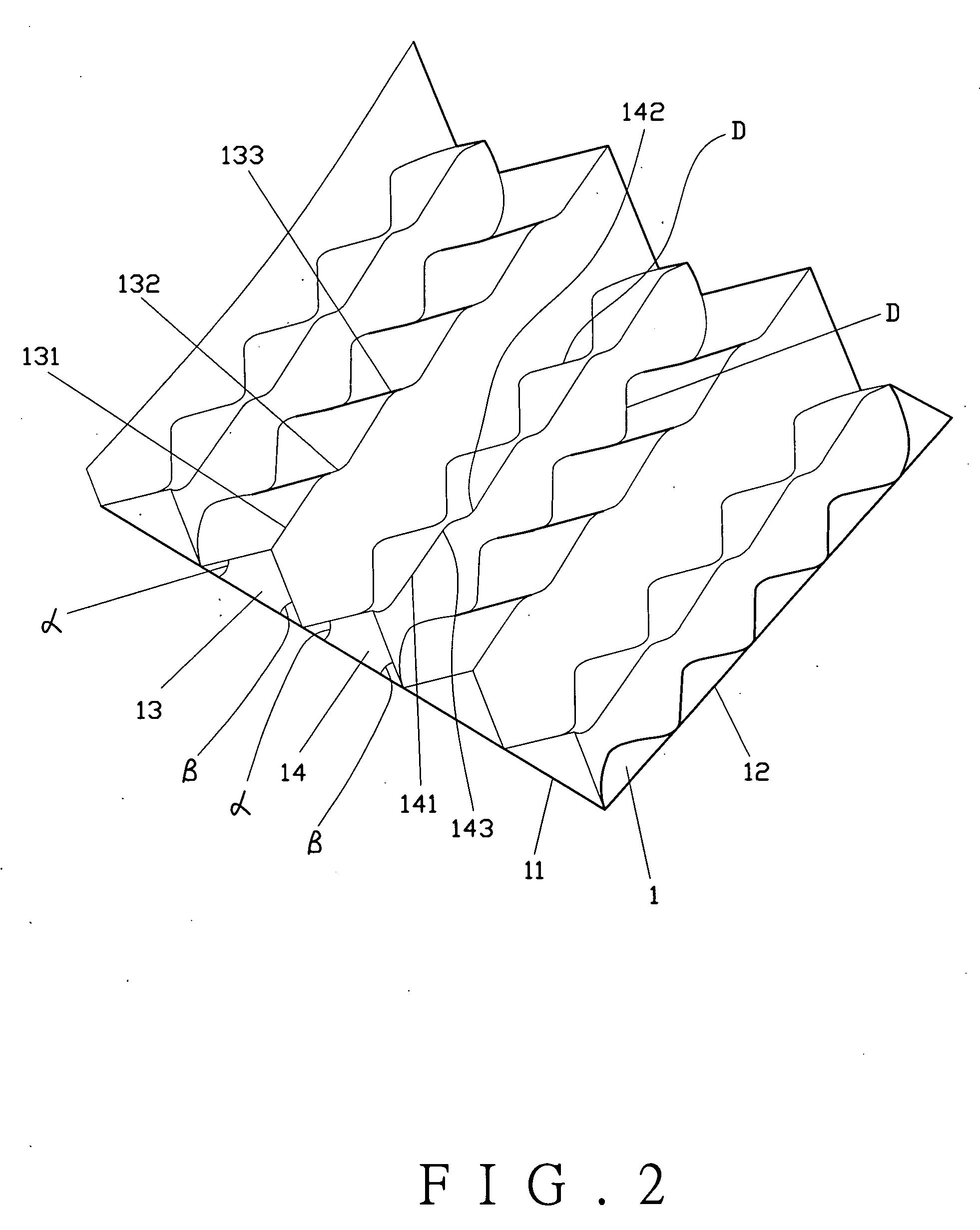

[0035]As shown in FIGS. 1 and 2, a brightness enhancement film 1 of the present invention comprises a pair of first sides 11 corresponding to each other, a pair of second sides corresponding to each other, and a number of first micro-reflectors 13 and second micro-reflectors 14 disposed side by side. Each of the first micro-reflectors 13 has a crest line 131, and each of the second micro-reflectors 14 has a crest line 141. The first micro-reflectors 13 have first average height and width which are different from second average height and width of the second micro-reflectors 14. The first average height of the first micro-reflectors 13 means the average value of the perpendicular heights of the micro-reflectors 13. The second average height of the second micro-reflectors 14 means the average value of the perpendicular heights of the second micro-reflectors 14. The first average width of the first micro-reflectors 13 means the average value of the width taken from the cross-section at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com