Molding apparatus and method with heat recovery

a technology of molding apparatus and heat recovery, which is applied in the direction of lighting and heating apparatus, stationary tubular conduit assemblies, indirect heat exchangers, etc., can solve the problems of increasing the temperature of water and cooling of molded products, and achieves the effects of saving energy, facilitating heating raw materials, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

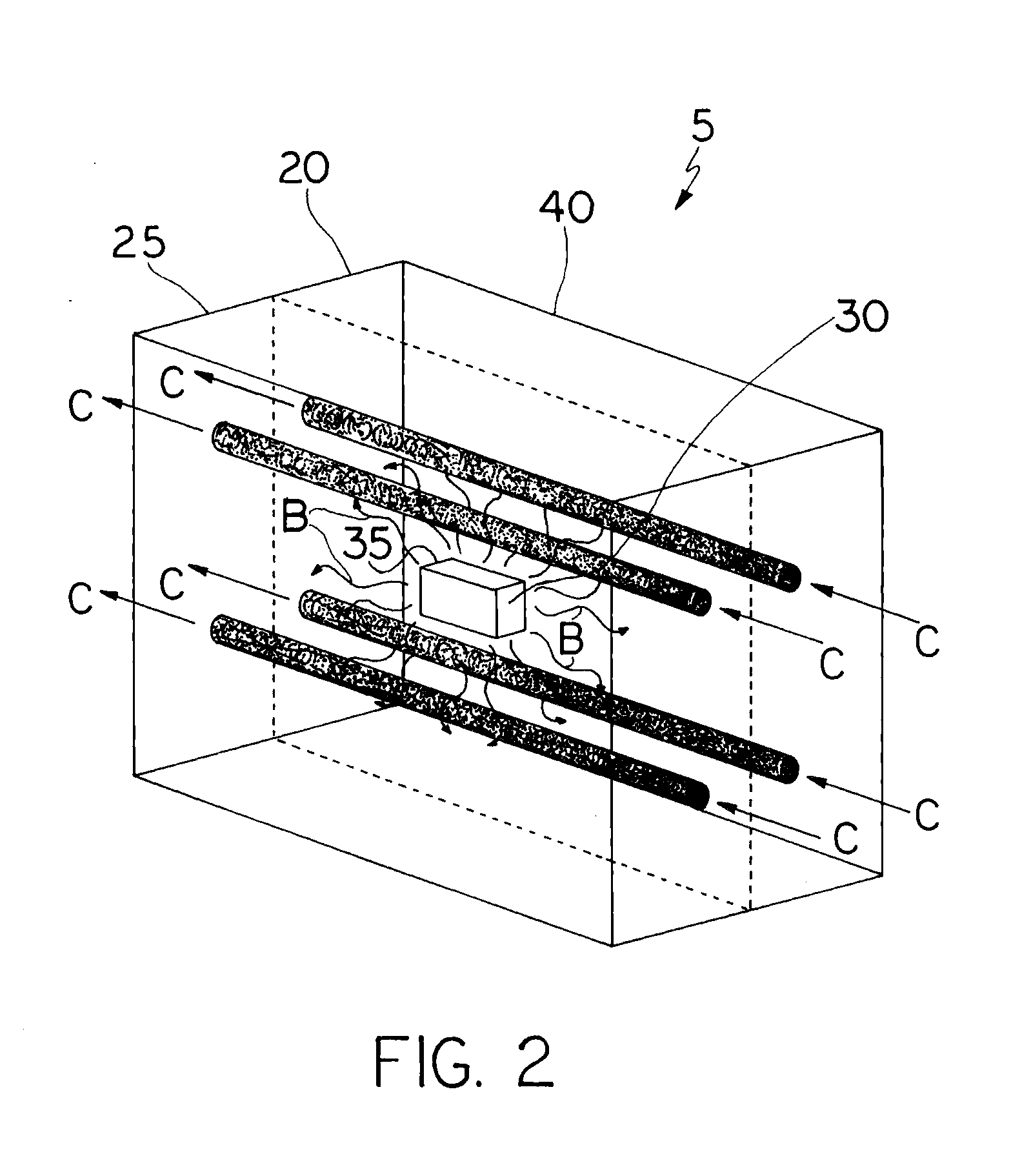

[0021]This invention relates to a molding apparatus, especially molding presses, and methods facilitating recapture and reuse of heat produced in the course of molding a product. More specifically, this invention provides apparatus and methods for recapturing heat produced in the course of fabricating a molded product and circulating the recaptured heat to raw material awaiting molding, to heat these materials prior to molding them, thereby reducing the amount of heat required during the actual molding process. Accordingly, this invention provides apparatus and methods for conserving energy in molding processes, thereby making the processes more energy and cost efficient.

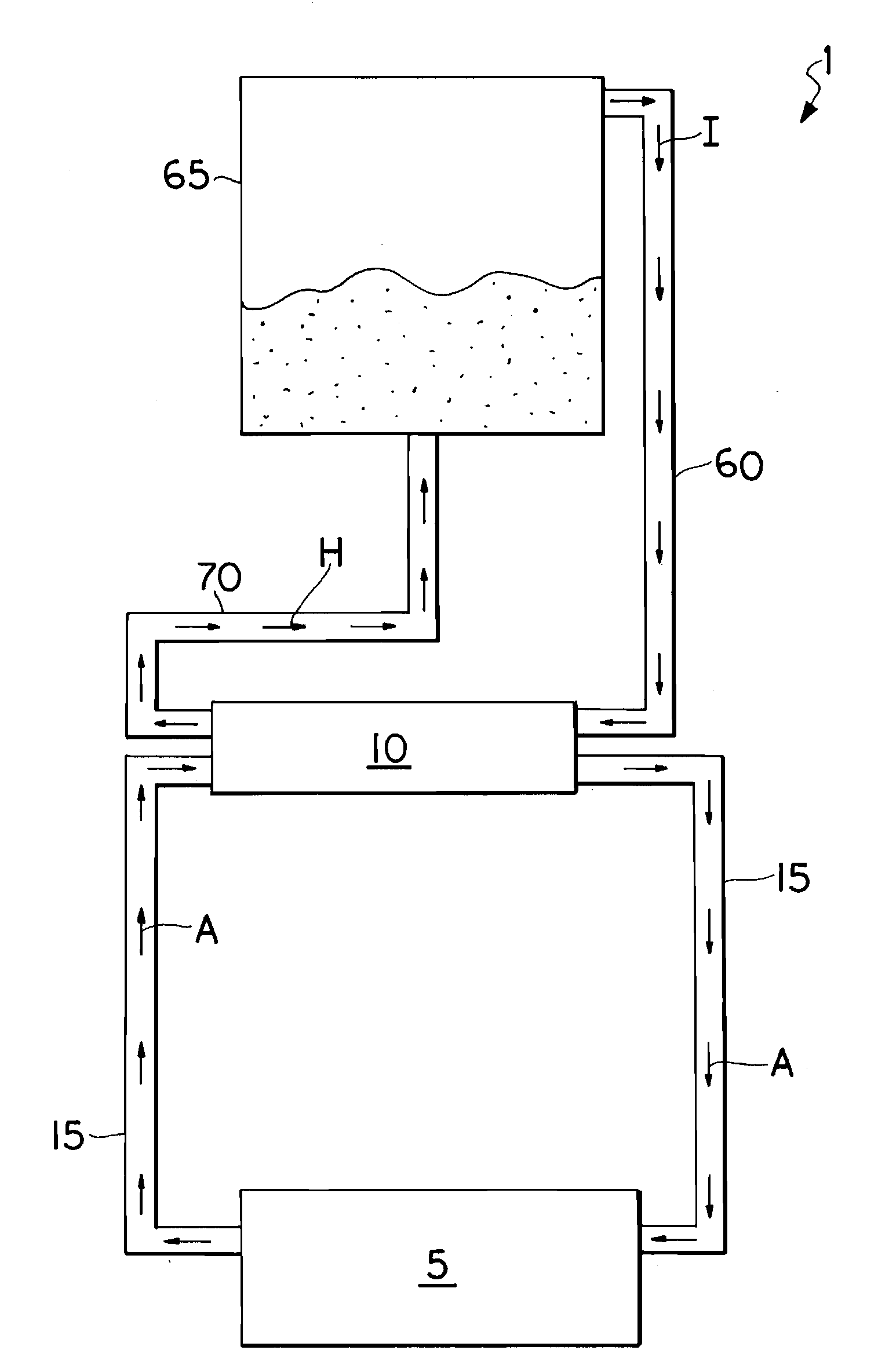

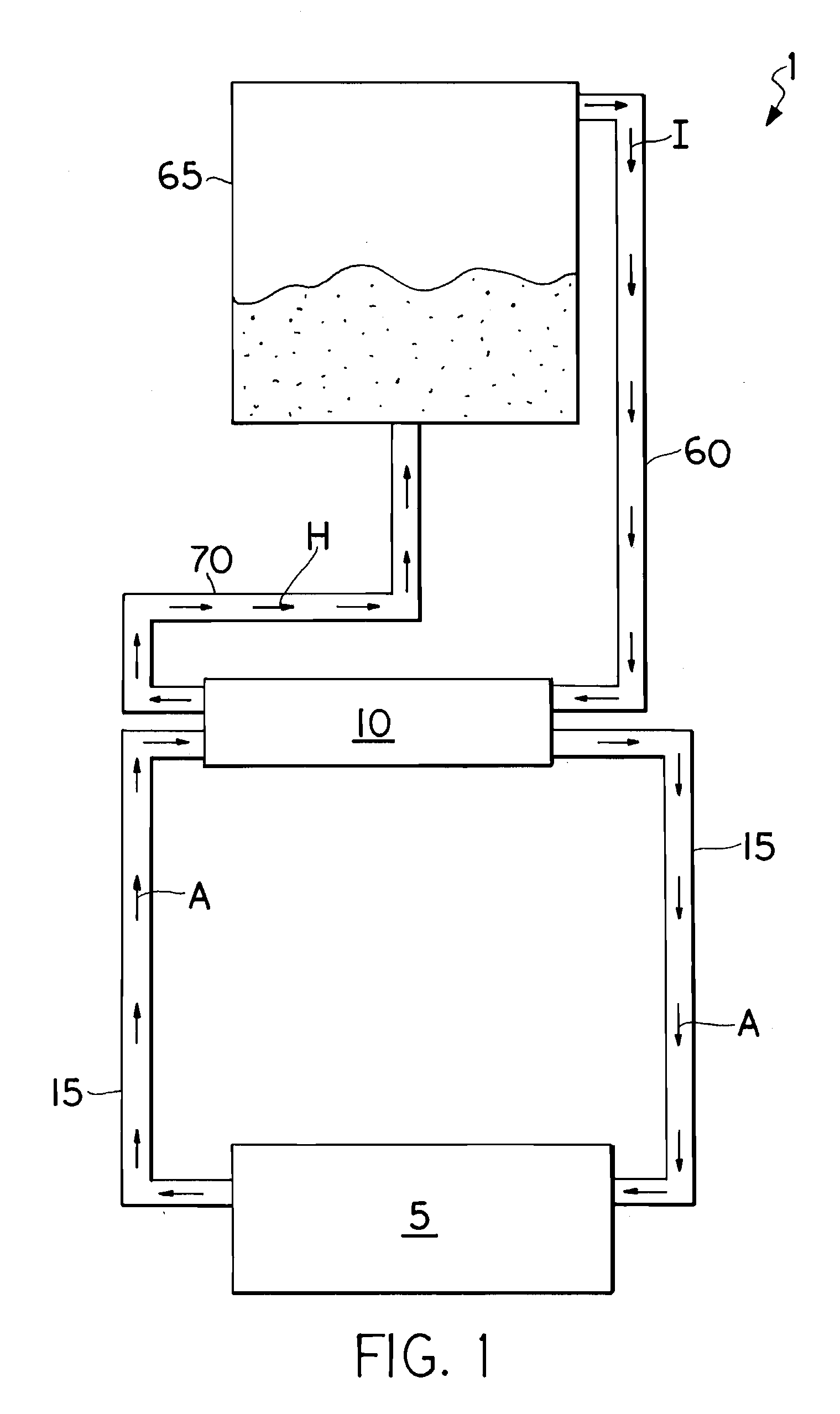

[0022]Referring to FIG. 1, a schematic, generic representation of apparatus manifesting aspects of the invention is generally indicated by reference number 1. In this embodiment of the invention, the apparatus includes, at least, a molding apparatus, desirably a molding press, illustrated schematically as 5, a heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| moldable | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com