Tool set for tucking bedsheets

a bedsheet and tool set technology, applied in the field of beds, can solve the problems of preventing the bedsheet from being properly tucked, affecting the tucking process, so as to reduce the amount of insertion of the lifter, stabilize the mattress lifter, and reduce the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

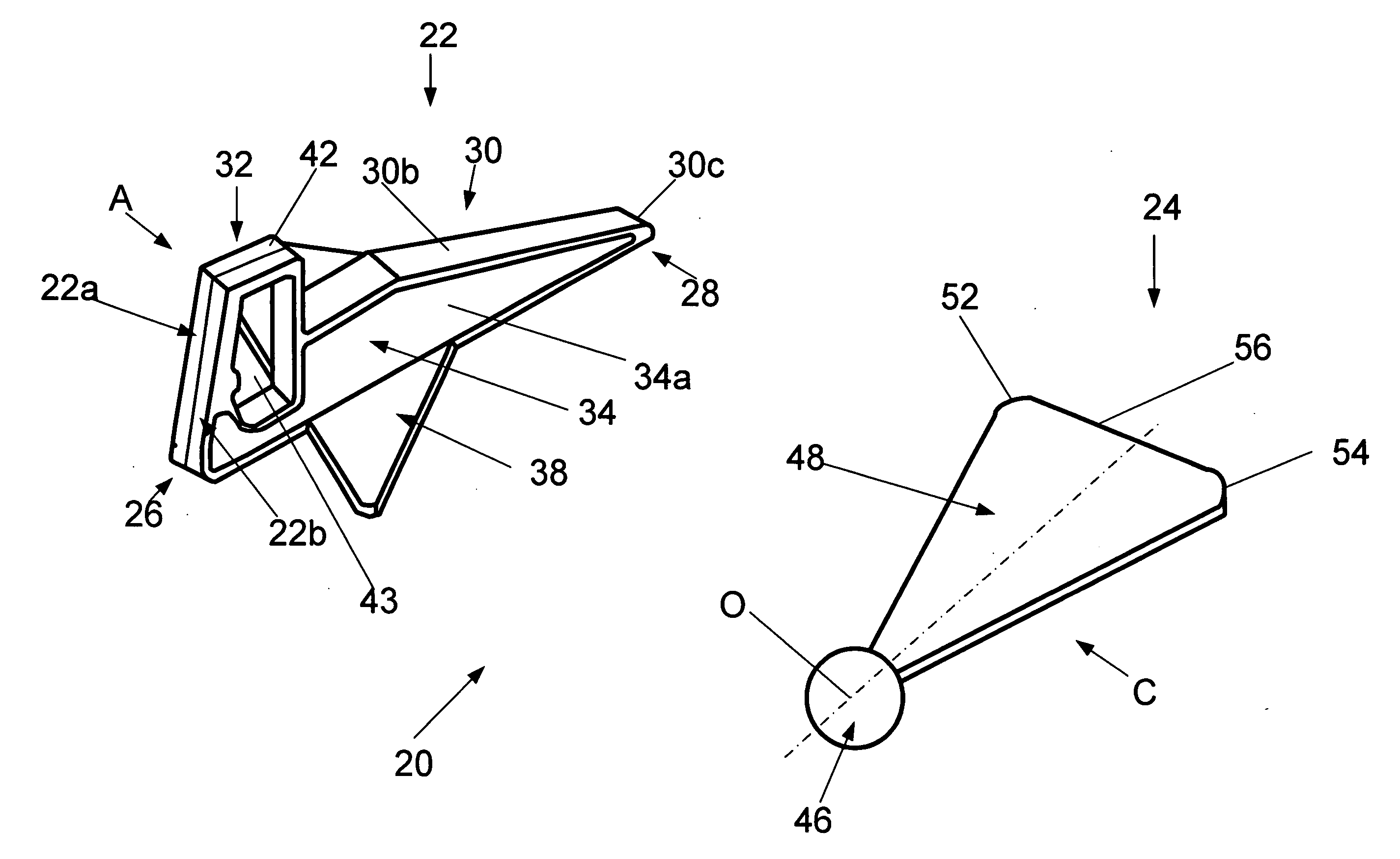

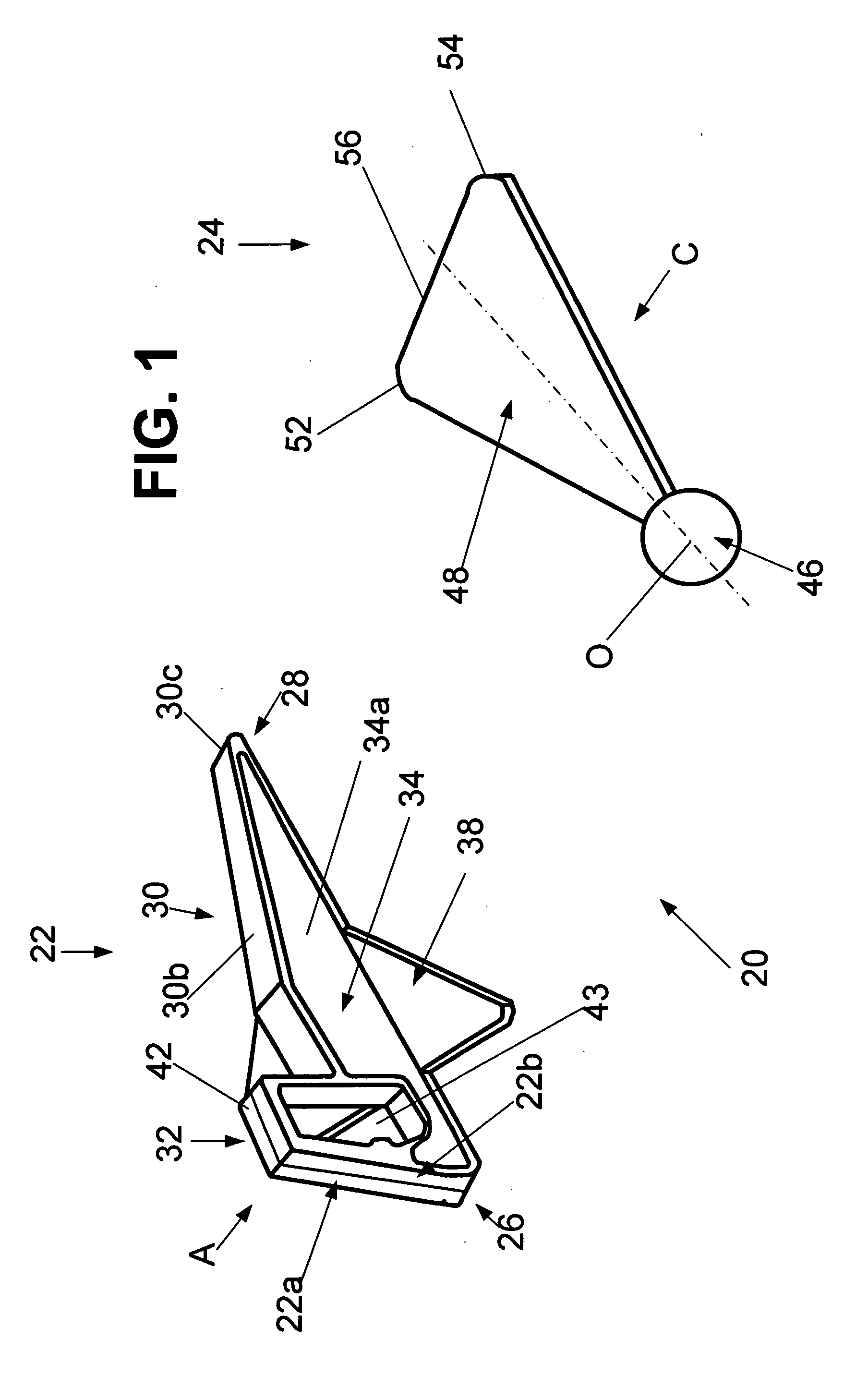

[0019]As shown in FIG. 1, which is a three-dimensional view of a bed tucking tool kit of the present invention, the kit, which is designated by reference numeral 20, consists of at least one mattress lifter 22 and at least one bedsheet tucker 24.

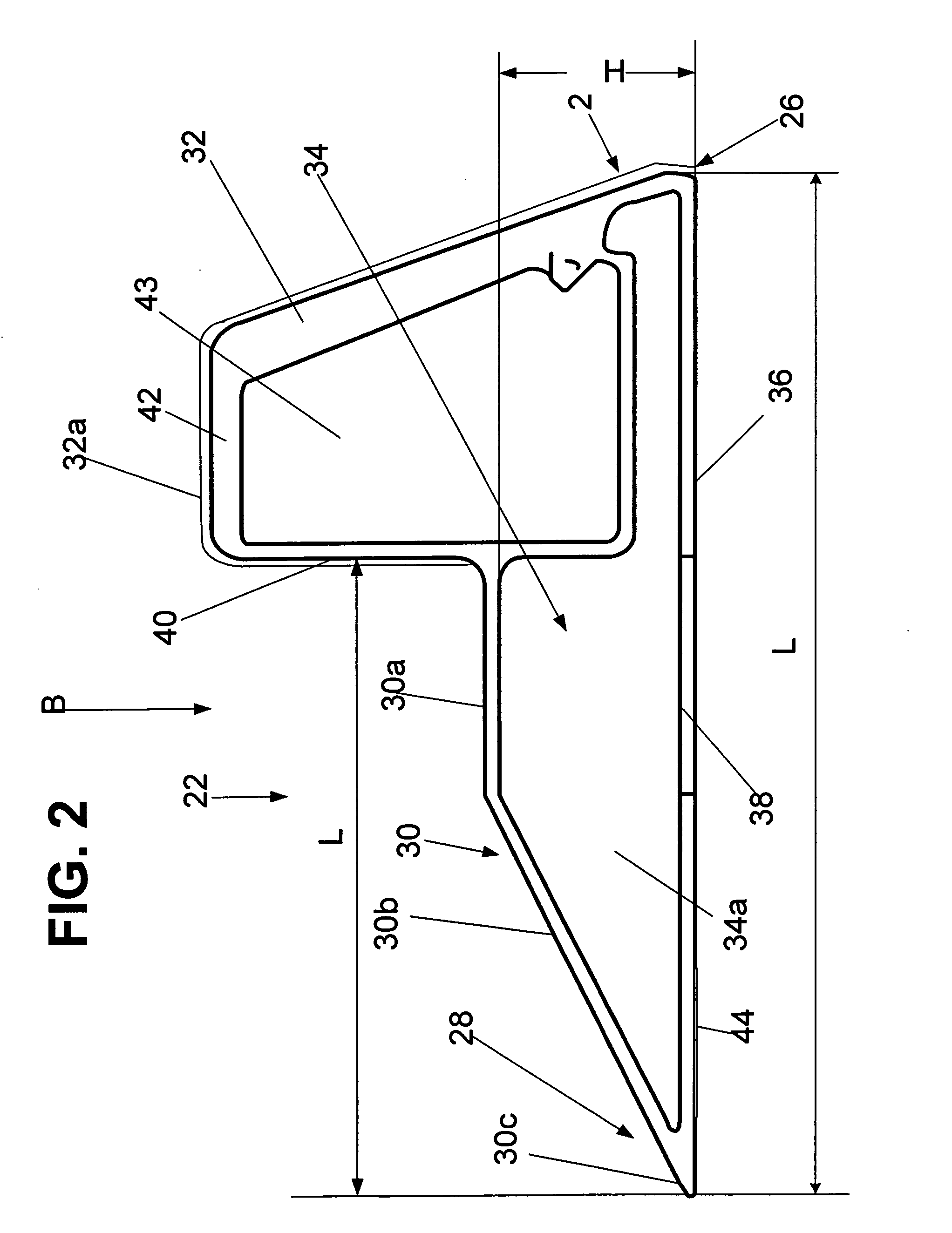

[0020]Let us first consider the mattress lifter 22 (hereinafter referred to as “lifter”). FIG. 2 is a-side view of the lifter 22 in the direction of arrow A in FIG. 1, FIG. 3 is a top view of the lifter 22 in the direction of arrow B in FIG. 2, and FIG. 4 is a three-dimensional view of the lifter 22 inserted into the interface F between a boxspring mattress M1 and a bed mattress M2 (the bedsheet is not shown in FIG. 4).

[0021]Preferably, the lifter 22 is a hollow plastic body molded from two halves 22a and 22b connected, e.g., glued or thermally bonded, to each other side by side along a split line 22c (FIG. 1). The lifter 22 has a proximal end 26, which is located on the side of the user (not shown), and a distal end 28 (FIG. 1), which is on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com