Packaged food products

a food product and packaging technology, applied in the field of packaging food products, can solve the problems of not being suitable for subsequent microwave reheating of food products before consumption, metal foil or metal, etc., and achieve the effects of minimizing heat loss, minimizing heating time, and minimizing thermal damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

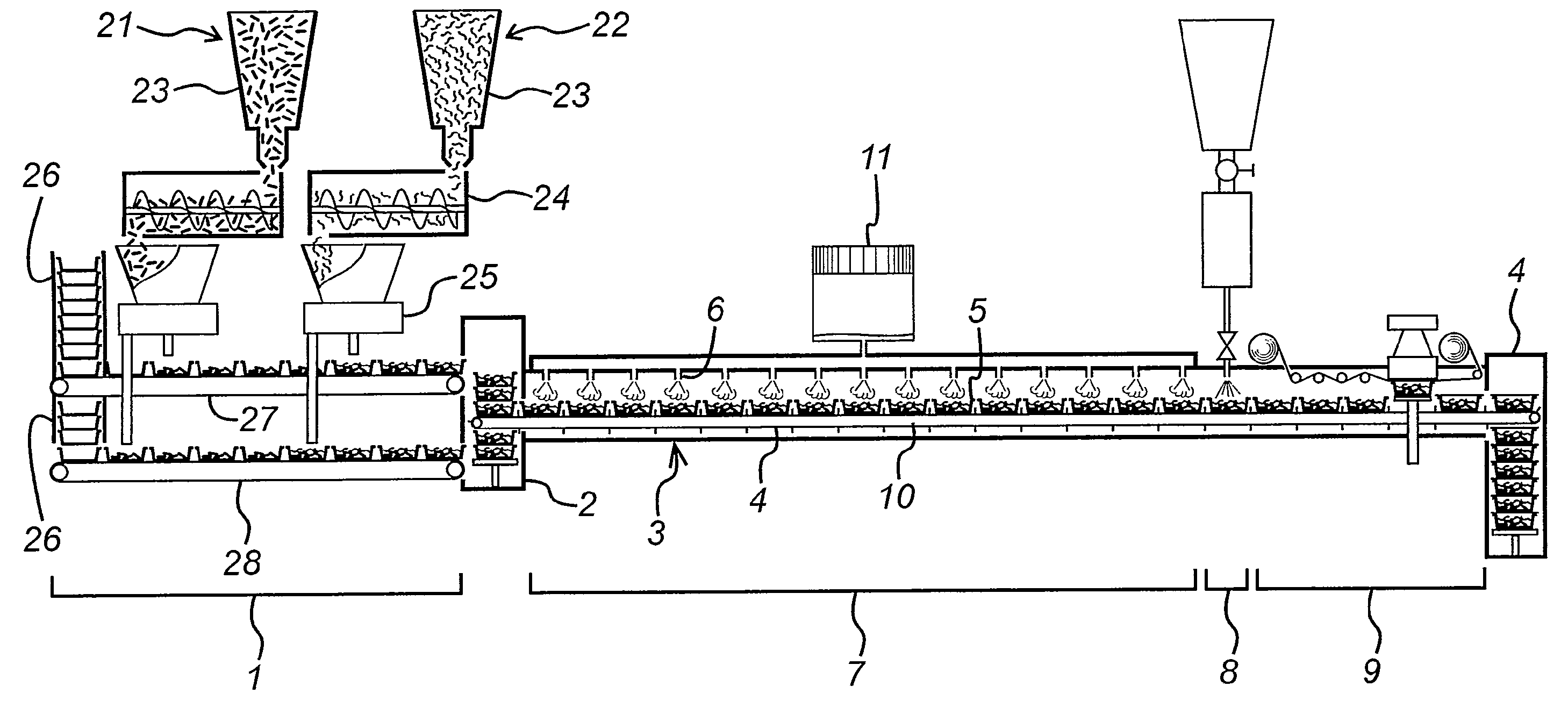

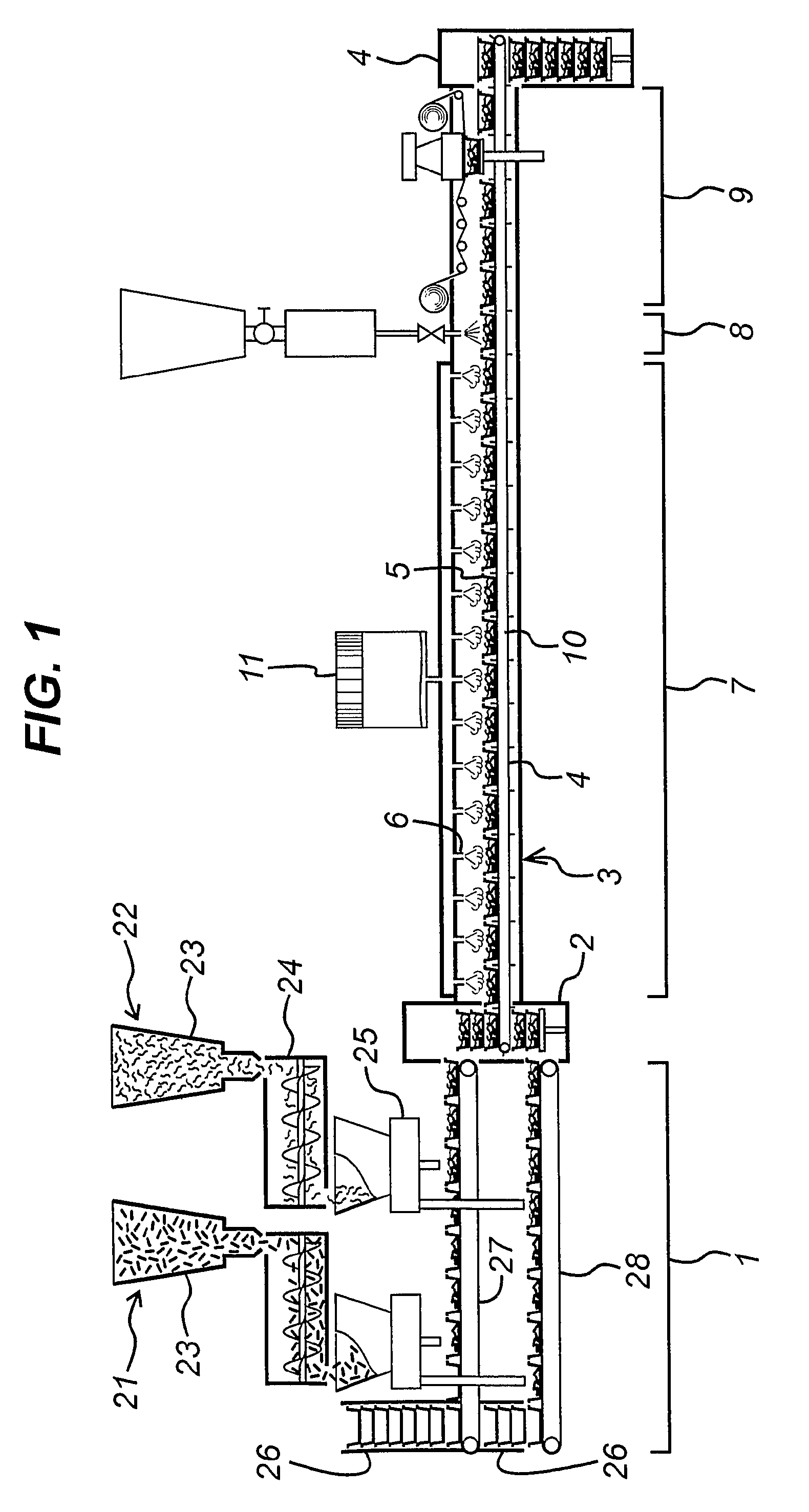

Method used

Image

Examples

reference example 1

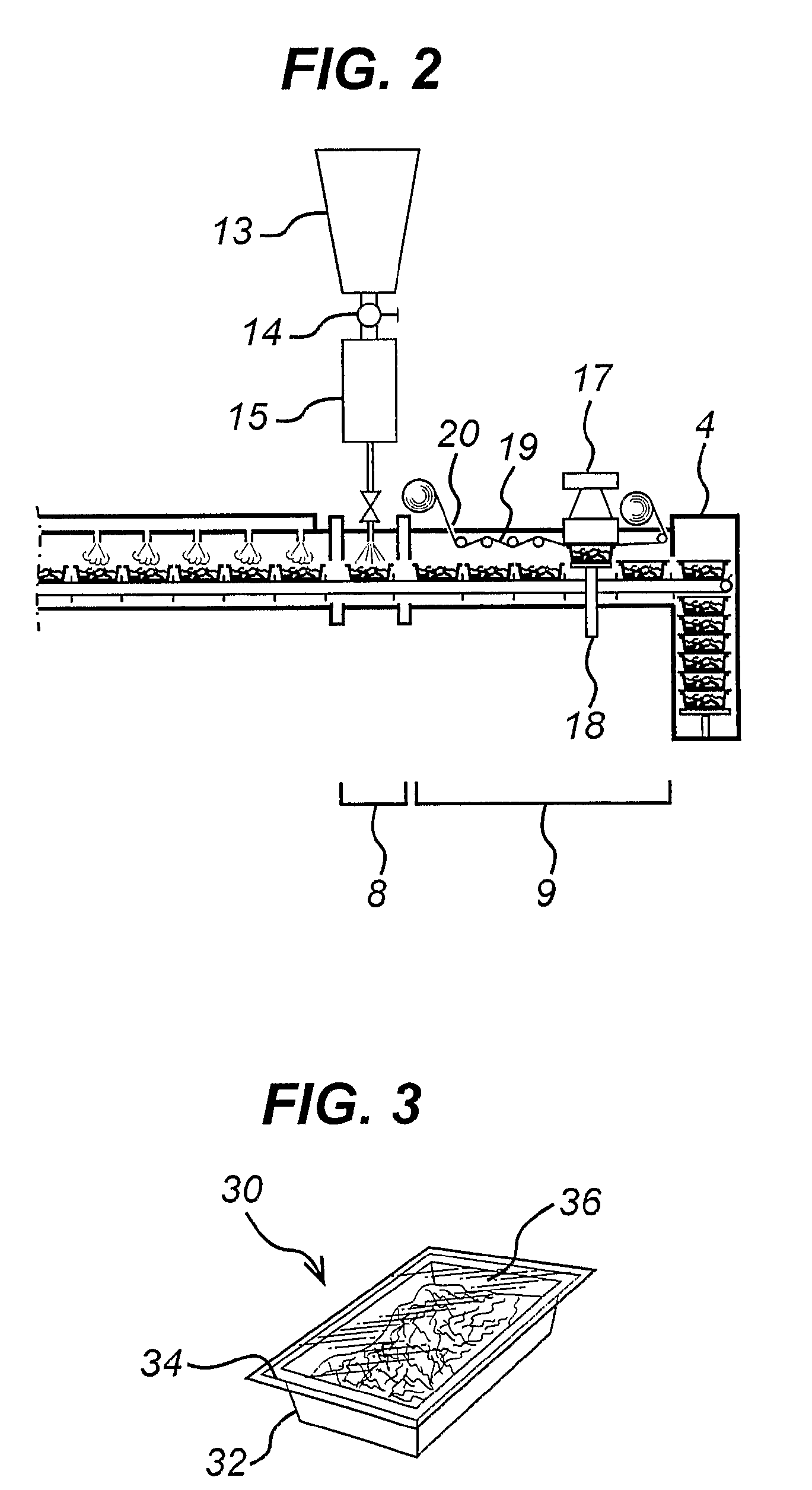

[0067]A bench-top simulation of the method according to the invention was performed as follows. A polypropylene tray was filled to a depth of about 1cm with dry, milled, parboiled long-grain rice having moisture content about 14 wt. %. The tray was introduced into a modified small retort and treated with steam at 135° C. for a time sufficient to achieve Fo of 5 minutes. The tray was then removed from the retort and liquid water at 100° C. was immediately added in an amount just sufficient to bring the total water content of the rice up to 65 wt. %. The tray was then immediately sealed by ultrasonically bonding a polypropylene film over the top of the tray. The tray and contents were then left to equilibrate for 30 minutes to 150 minutes at temperatures in the range 40° C. to 80° C.

[0068]The packaged rice product obtained by this method was ambient stable and had a natural, freshly cooked appearance. It could be reheated for immediate consumption. The reheated product was completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com