Variable focus liquid filled lens apparatus

a liquid-filled lens and variable focus technology, applied in the field of consumer ophthalmic lenses, can solve the problems of loss of stereopsis (depth perception), drop in reading speed and comprehension rate, and hasten the onset of fatigu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The following preferred embodiments as exemplified by the drawings are illustrative of the invention and are not intended to limit the invention as encompassed by the claims of this application.

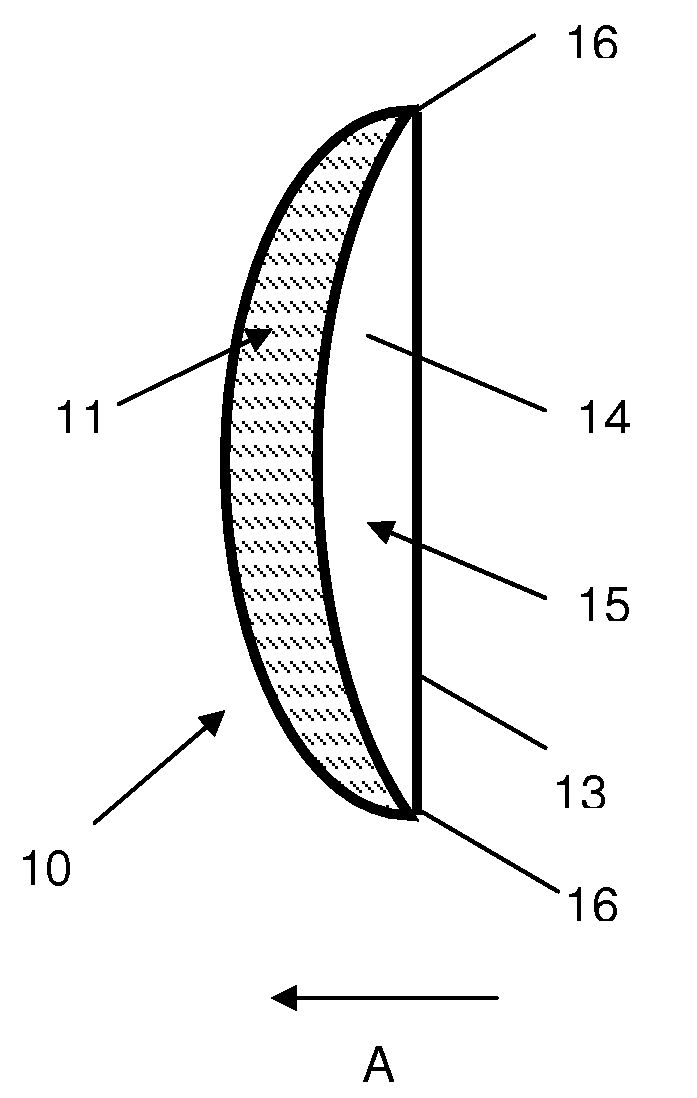

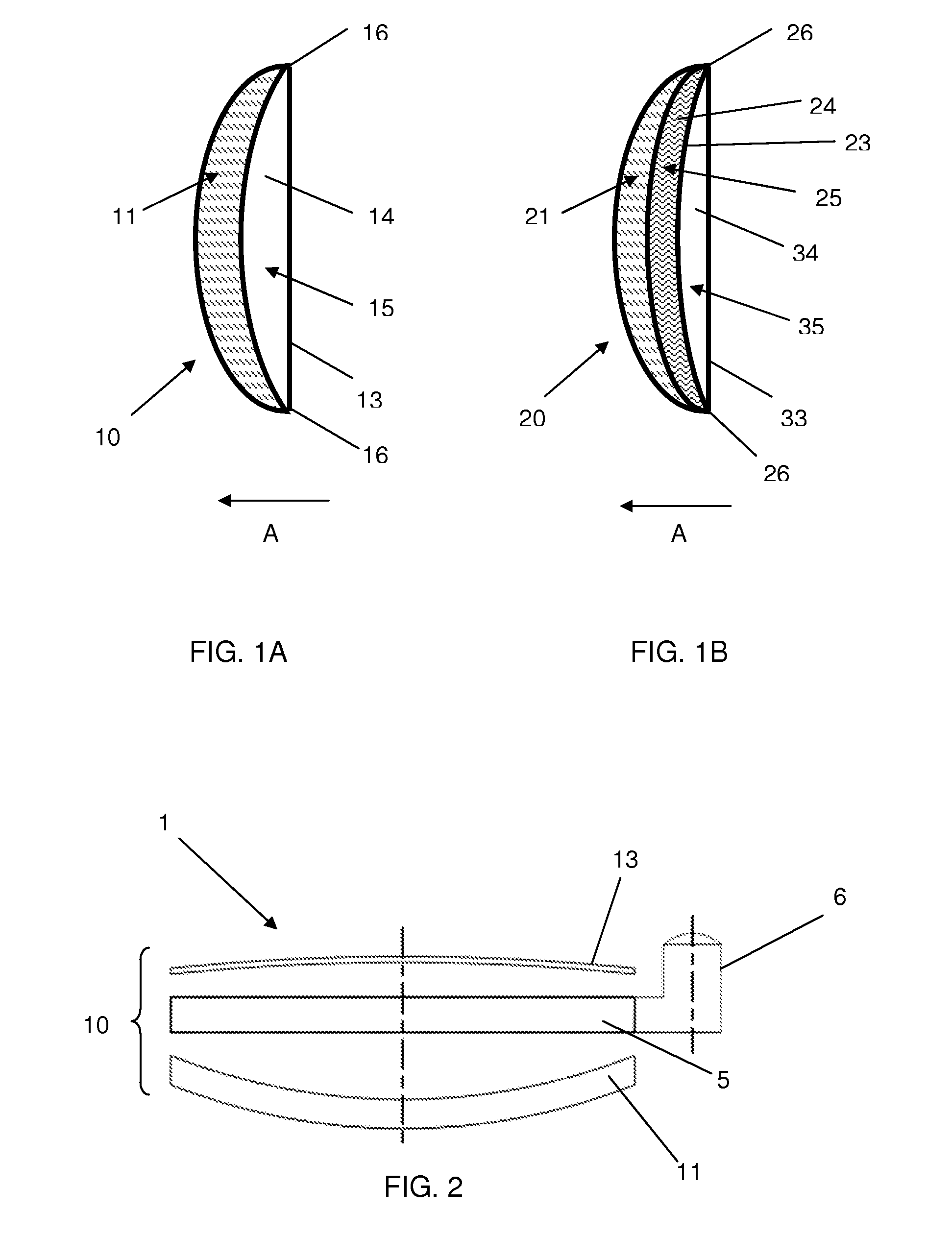

[0024]FIG. 1A shows a cross-sectional view of a first preferred embodiment of the optical apparatus, in the form of a variable focus lens 10, through which a wearer peers in the direction of arrow A. Lens 10 is a composite of two optic components, an anterior (i.e., front, with respect to the wearer) optic 11 that is substantially rigid and a posterior (i.e., back, with respect to the wearer) optic 15 that is a liquid.

[0025]Anterior optic 11 is a substantially rigid lens preferably made of a rigid, transparent substrate, such as a clear plastic or poly carbonate, glass plate, transparent crystal plate, or a transparent rigid polymer, for example, Polycarbonate of Bisphenol A or CR-39 (Diethylene glycol bisallyl carbonate). Anterior optic 11 may be made of an impact resistant polymer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com