Surface light source and liquid crystal display device using the same

A surface light source and light source technology, applied in the direction of light source, slender light source, lighting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

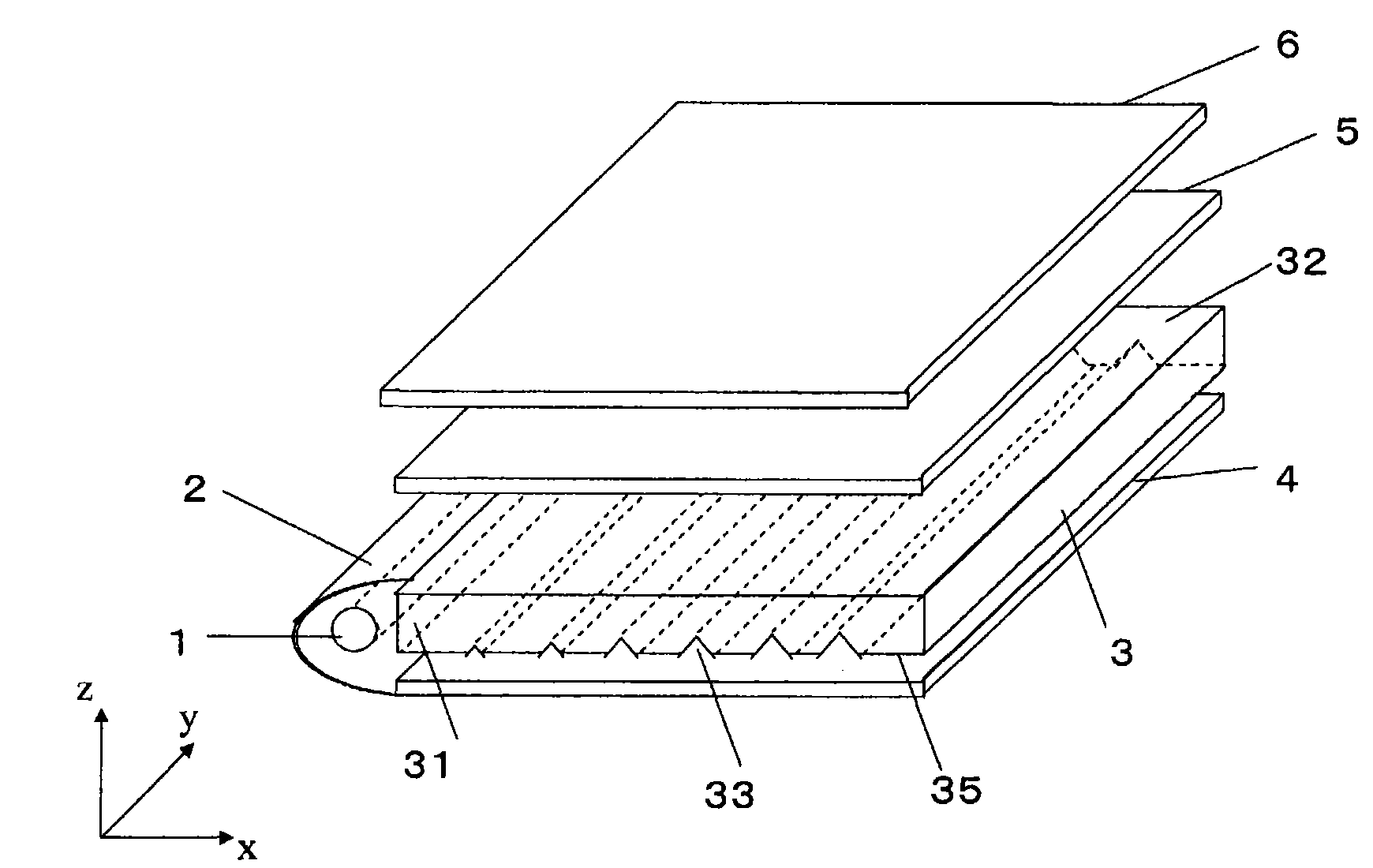

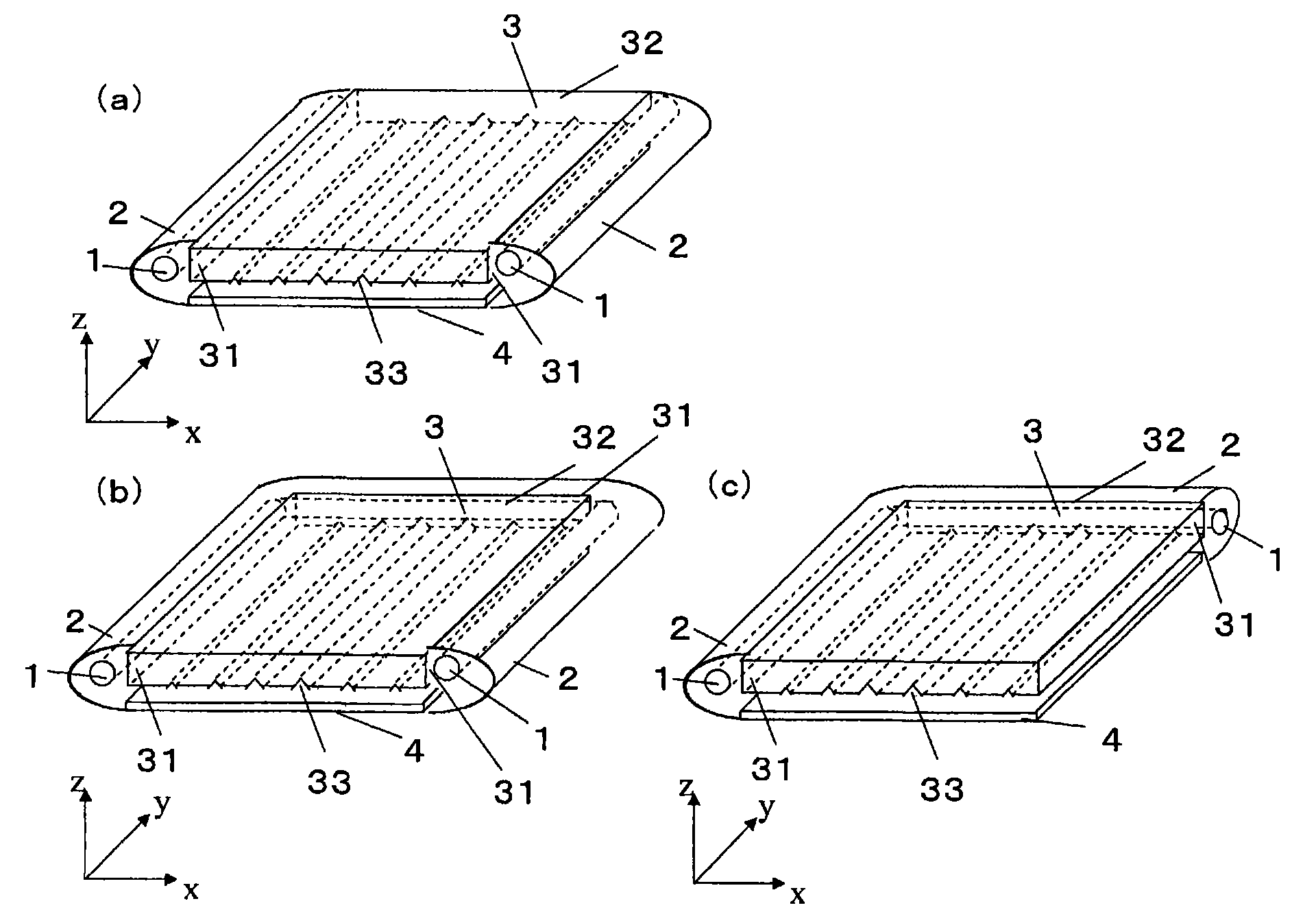

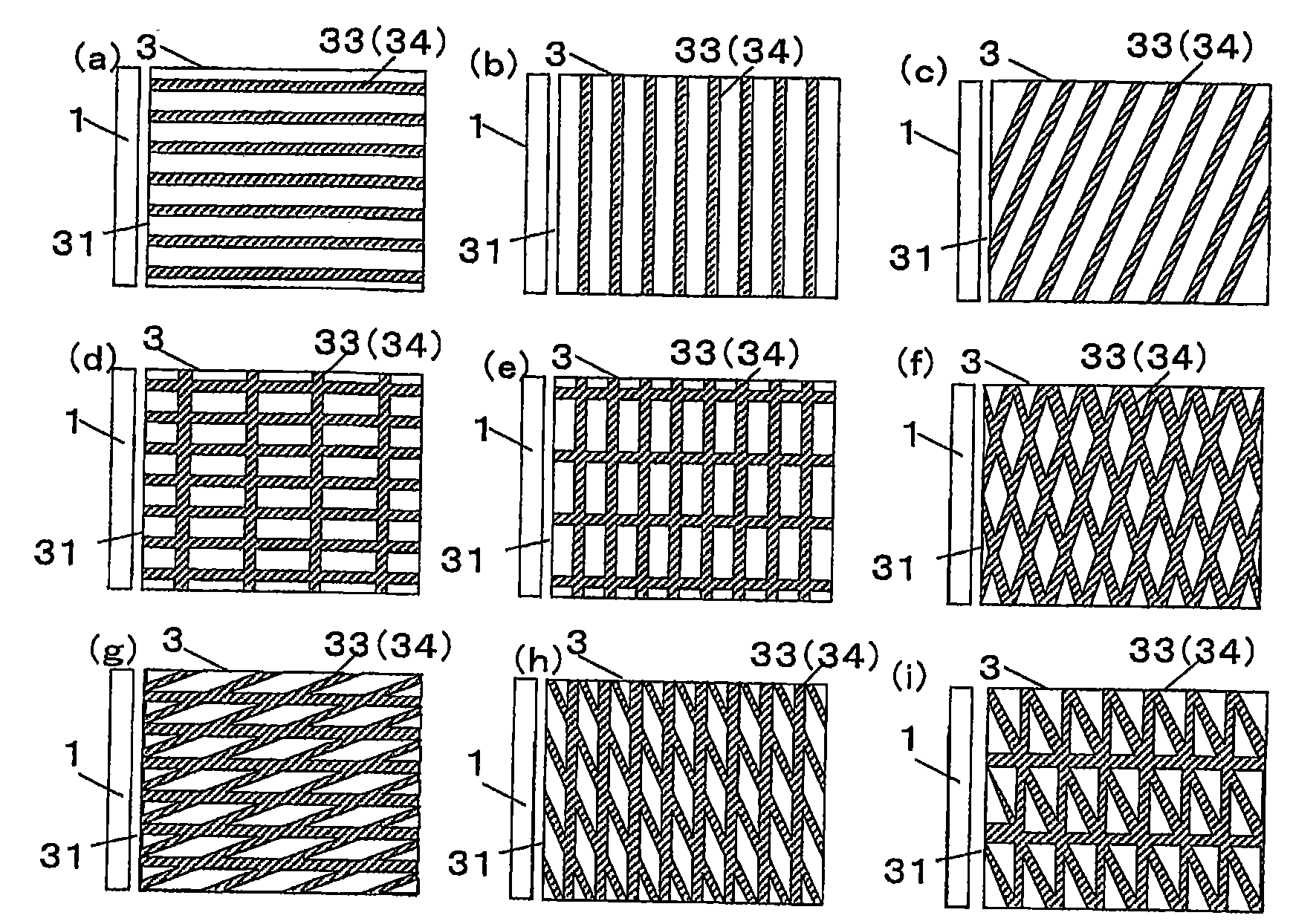

[0368] The light guide A-1 is installed in such a way that the surface without linear grooves is on the observer side, and two cold cathode fluorescent lamps (hereinafter referred to as CCFLs) are respectively installed on the two opposite light incident surfaces. "Lumiraichi" E6SV (manufactured by Toray Co., Ltd.) is installed around as a reflector. On the non-observer side of the light guide 3, a reflective sheet "Lumira" E6SL (manufactured by Toray Co., Ltd.) is provided. On the viewer side of the light guide 3, B-1 is used as the first optical film so that the direction in which the anisotropic diffusivity becomes the largest is parallel to the longitudinal direction of the linear groove of the light guide 3 (that is, θ5=0 °) configuration. C-1 is used as the second optical film on the first optical film B-1 so that its prism length direction is parallel to the direction in which the anisotropic diffusivity of the optical film B-1 becomes maximum (that is, θ6=0°). Mode s...

Embodiment 1-2

[0371] Except having used B-2 as a 1st optical film, it carried out similarly to Example 1-1, and produced the surface light source.

[0372] After lighting for 10 minutes, measure the brightness of 25 points in the surface light source (refer to Figure 18 (a)), it was found that the central brightness is 6950cd / m 2 (Evaluation A), the uniformity U was 81% (Evaluation A), and it was found that the center brightness and the uniformity U were good. In addition, the emission angle distribution from the central part of the surface light source was measured, and the viewing angle was found to be 30° in the vertical direction (evaluation A) and 45° in the horizontal direction (evaluation A), showing good viewing angle characteristics (see Table 4).

Embodiment 1-3

[0374] Except having used B-3 as a 1st optical film, it carried out similarly to Example 1-1, and produced the surface light source.

[0375] After lighting for 10 minutes, measure the brightness of 25 points in the surface light source (refer to Figure 18 (a)), it was found that the central brightness is 6690cd / m 2 (Evaluation C), the uniformity U was 85% (Evaluation A), and it was found that the center brightness and the uniformity U were good. In addition, the emission angle distribution from the center of the surface light source was measured, and the viewing angle was found to be 32° in the vertical direction (evaluation A) and 47° in the horizontal direction (evaluation A), showing good viewing angle characteristics (see Table 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Center brightness | aaaaa | aaaaa |

| Center brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com