Optical membrane structure and manufacturing method thereof

A technology of optical film and manufacturing method, which is applied in optics, optical components, nonlinear optics, etc., and can solve the problems of affecting test results, appearance defects, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

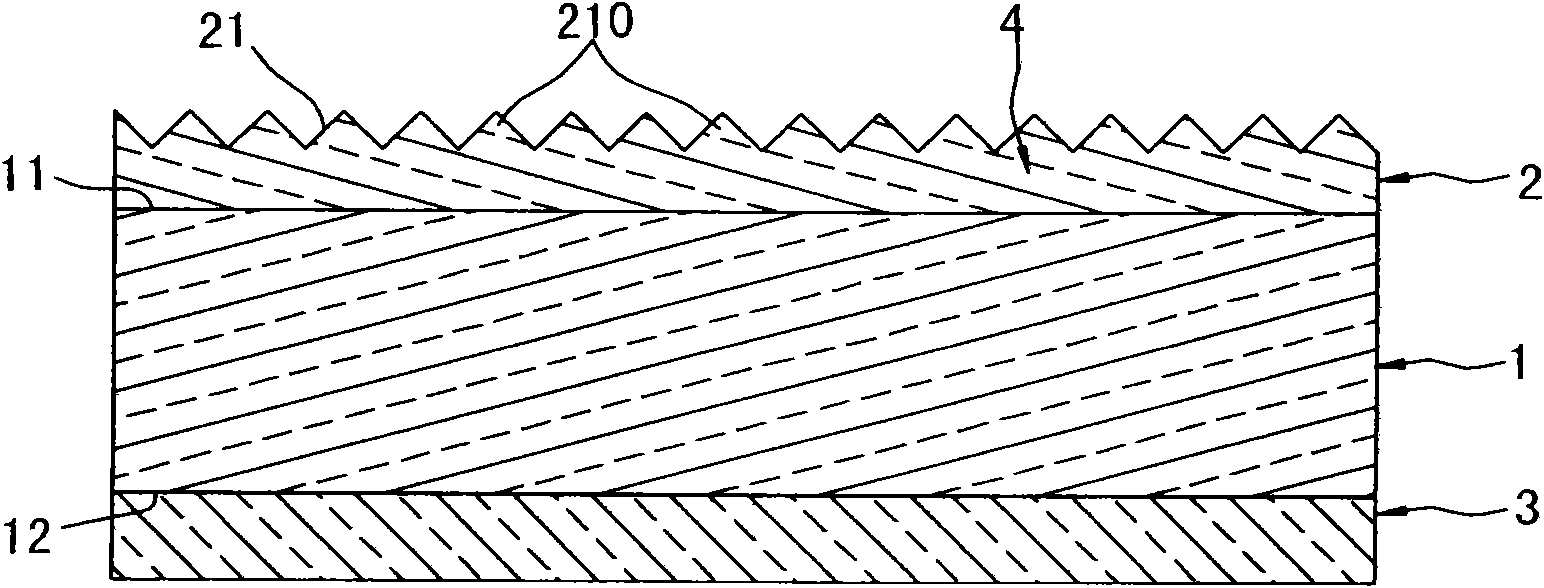

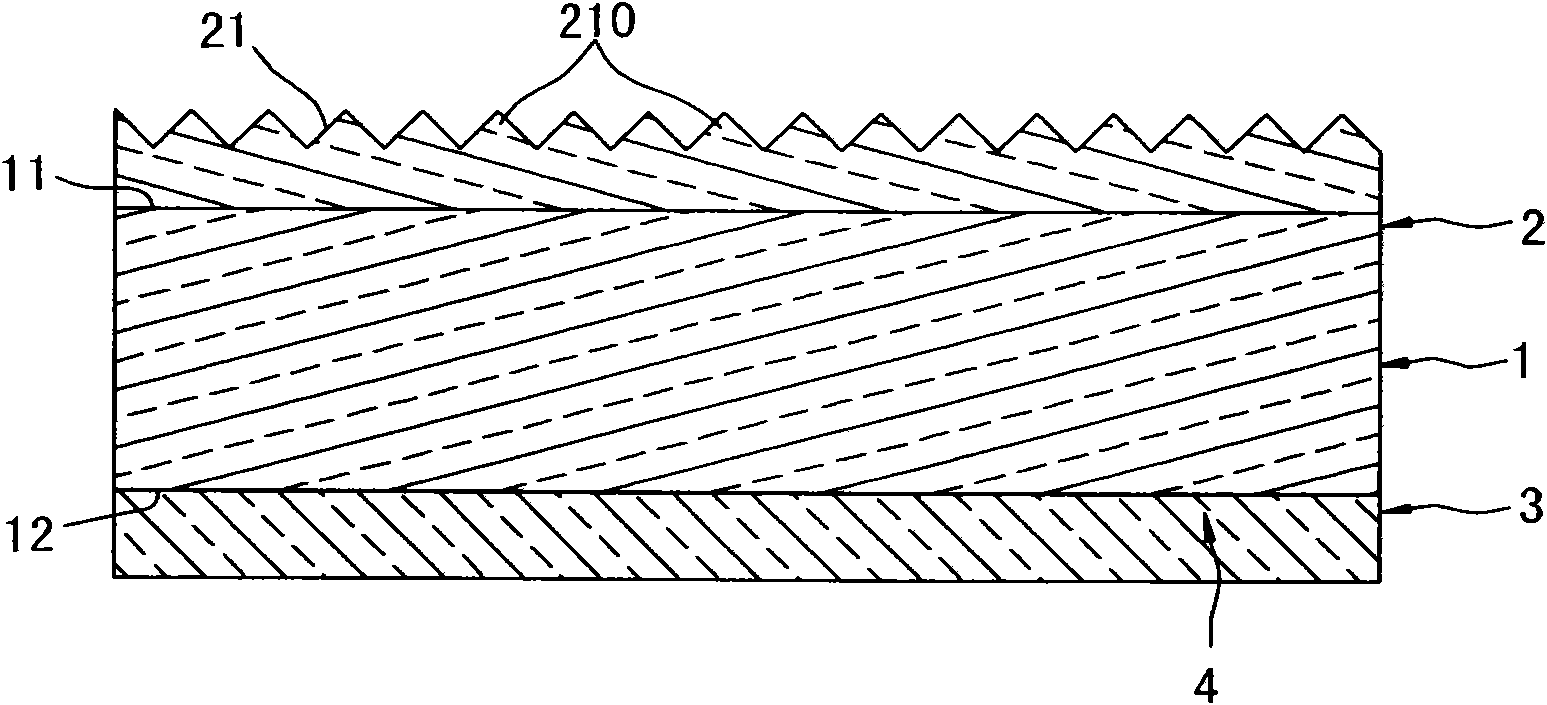

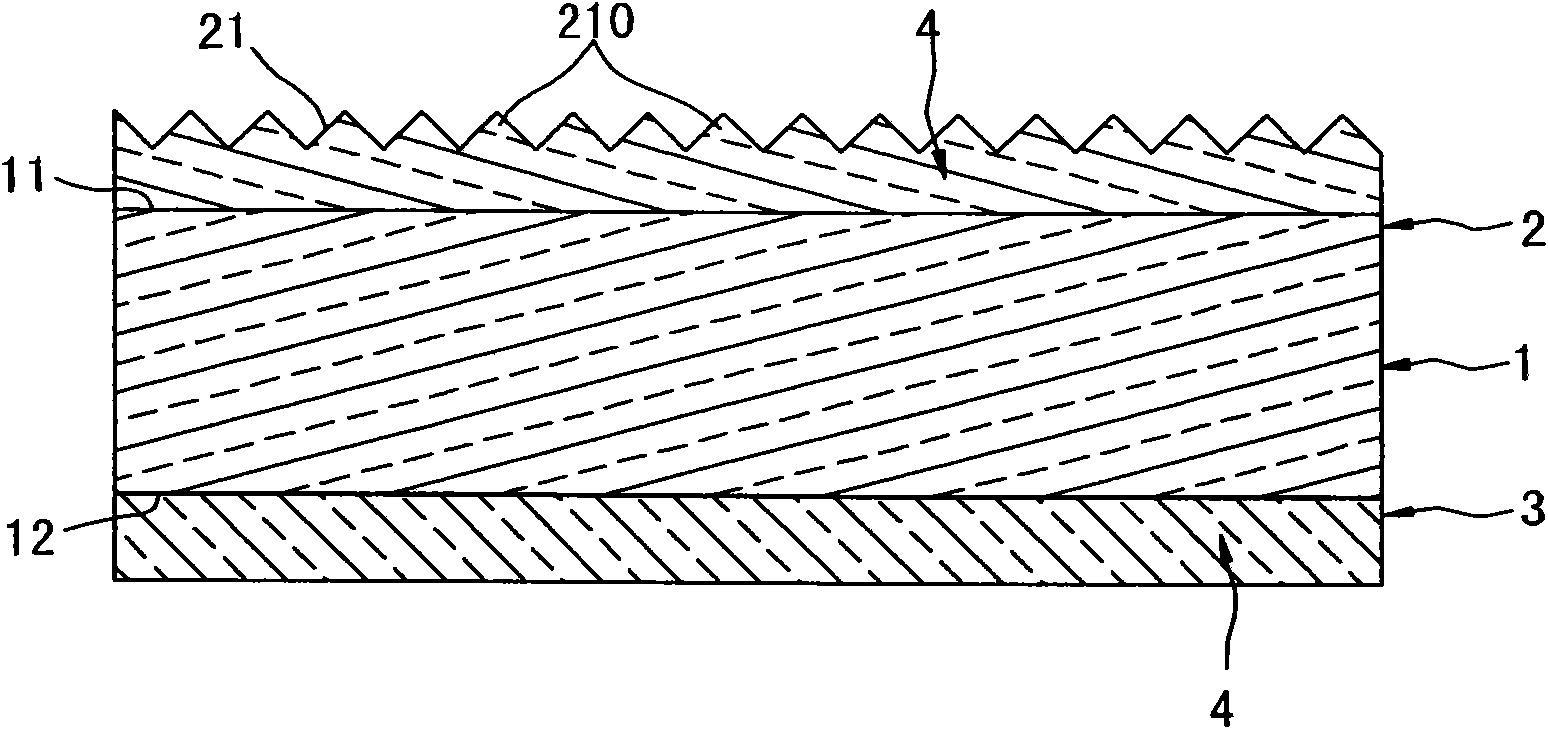

[0033] see figure 1 As shown, it is a schematic view of the first embodiment of the structure of the optical film of the present invention, and its structure includes: a base material layer 1 , a first light-transmitting layer 2 and a second light-transmitting layer 3 . Through the co-extrusion process, the substrate layer 1 , the first and second transparent layers 2 and 3 can be combined into one. Wherein, the substrate layer 1, the first and the second light-transmitting layers 2, 3 are plastic materials, and the plastic materials can be polystyrene (PS), polymethyl methacrylate-polystyrene copolymer (MS) , polycarbonate (PC), polyethylene terephthalate (PET), COP, polypropylene (PP) or acrylic (PMMA) or plastic materials equivalent to the above materials.

[0034] The substrate layer 1 is the main structure of the optical film structure, which has a light-emitting surface 11 and a light-incident surface 12 opposite to the light-emitting surface 11, serving as the bonding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com