Vertical air compliant hemming head

a hemming head and vertical air technology, applied in the field of hemming sheet metal, can solve the problems of imperfect hemming of the workpiece, insufficient springs alone, and robots that are not composed of a perfectly rigid body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The joining of a pair of panel edges by hemming is conventional and described herein by way of providing background as to the application of the hemming operation using the hemming apparatus 10 according to the invention herein. Further, the robot machine, including the robot arm and the robot hand, are also well known in the art and their description is omitted.

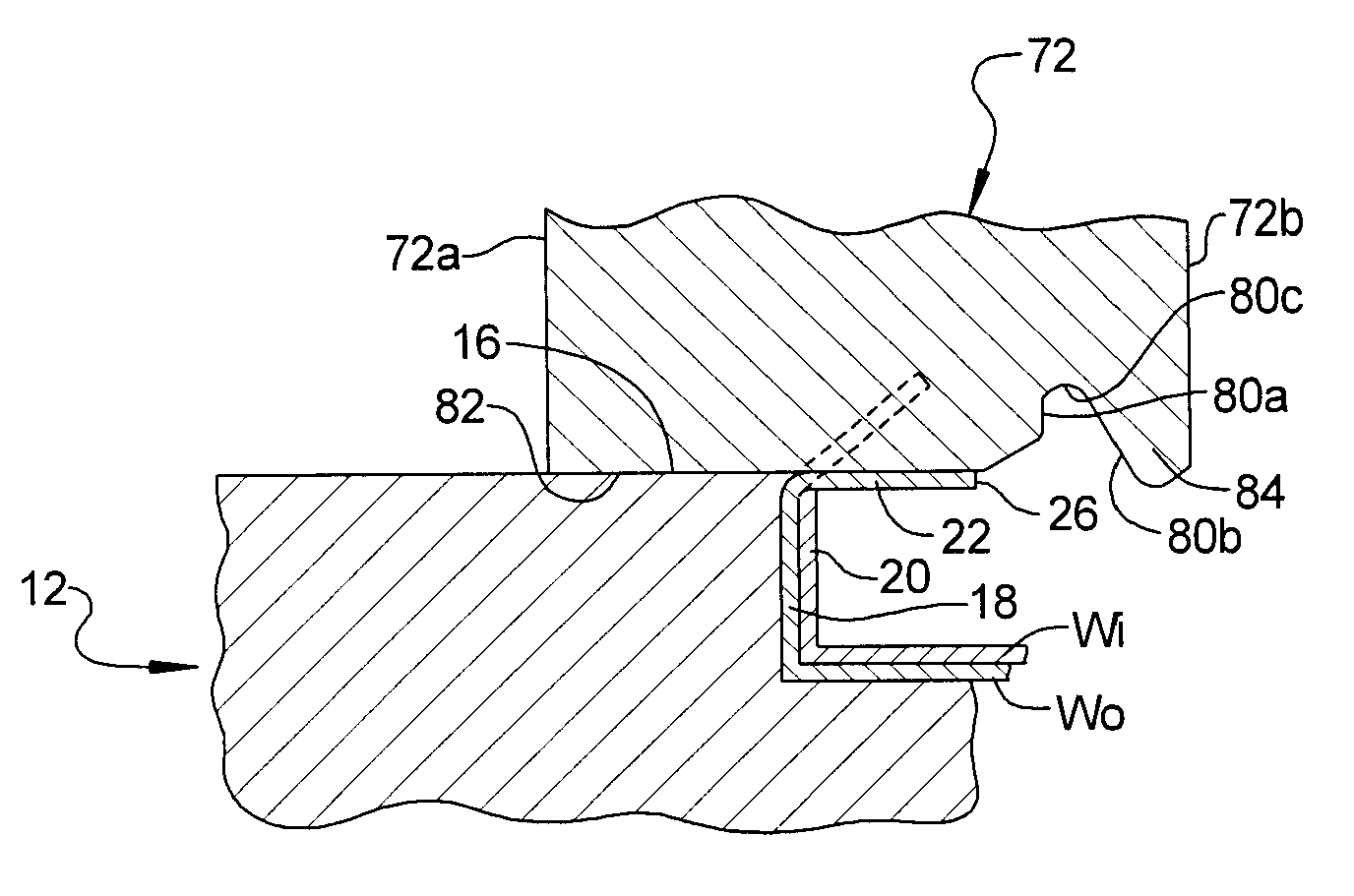

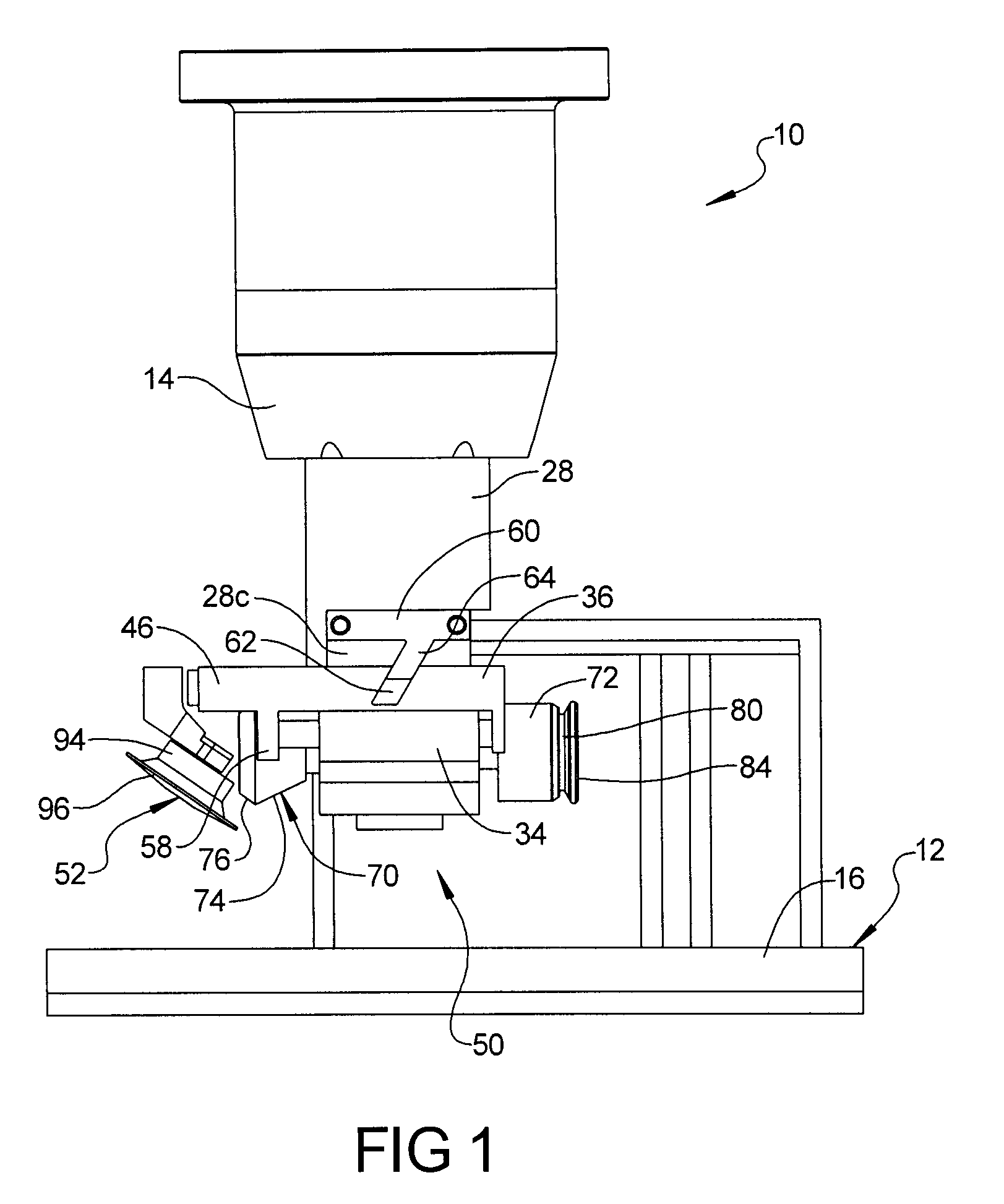

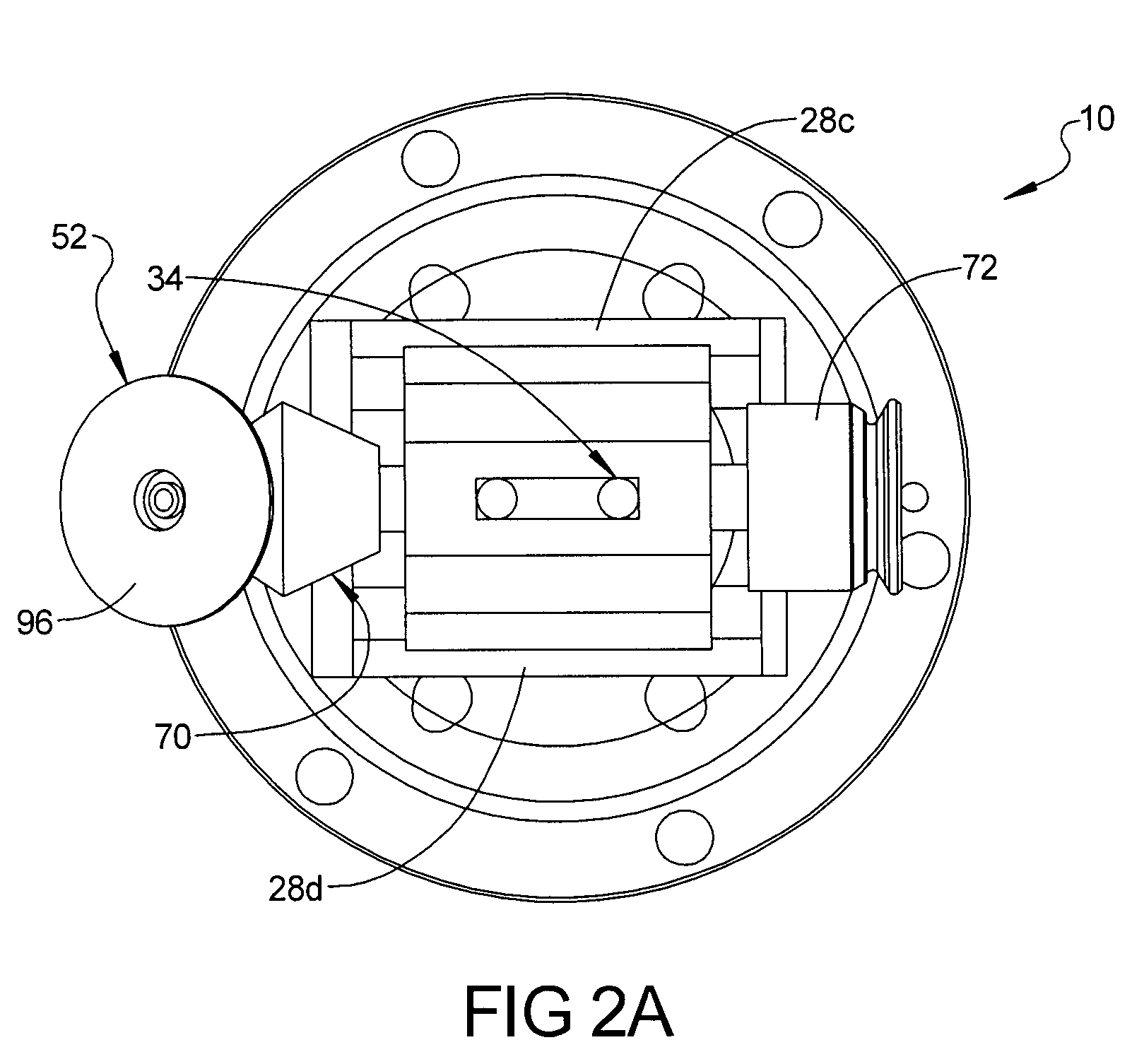

[0052]Referring now to the drawings, FIG. 1 is an environmental elevation view of a roller-type hemming apparatus 10 according to this invention positioned above a support frame 12 that is adapted to support a workpiece W. The hemming apparatus 10 includes a hemming head 14 that is operably connected to a work arm, such as provided on a multi-axis controllable robot hand, and is constrained for movement along a predetermined travel path around the frame 12 and relative to the workpiece W. The frame 12 is configured to nest or otherwise support the specific workpiece and includes a support anvil 16 that supports a roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com