System and Method for Utilizing Plastic Conductive Gaskets

a technology of conductive gaskets and plastics, applied in the field of electric conductive plastics, can solve problems such as radiation electrical emissions, and achieve the effects of reducing or eliminating the risk of electrical shorts, reducing or eliminating the probability of gasket failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

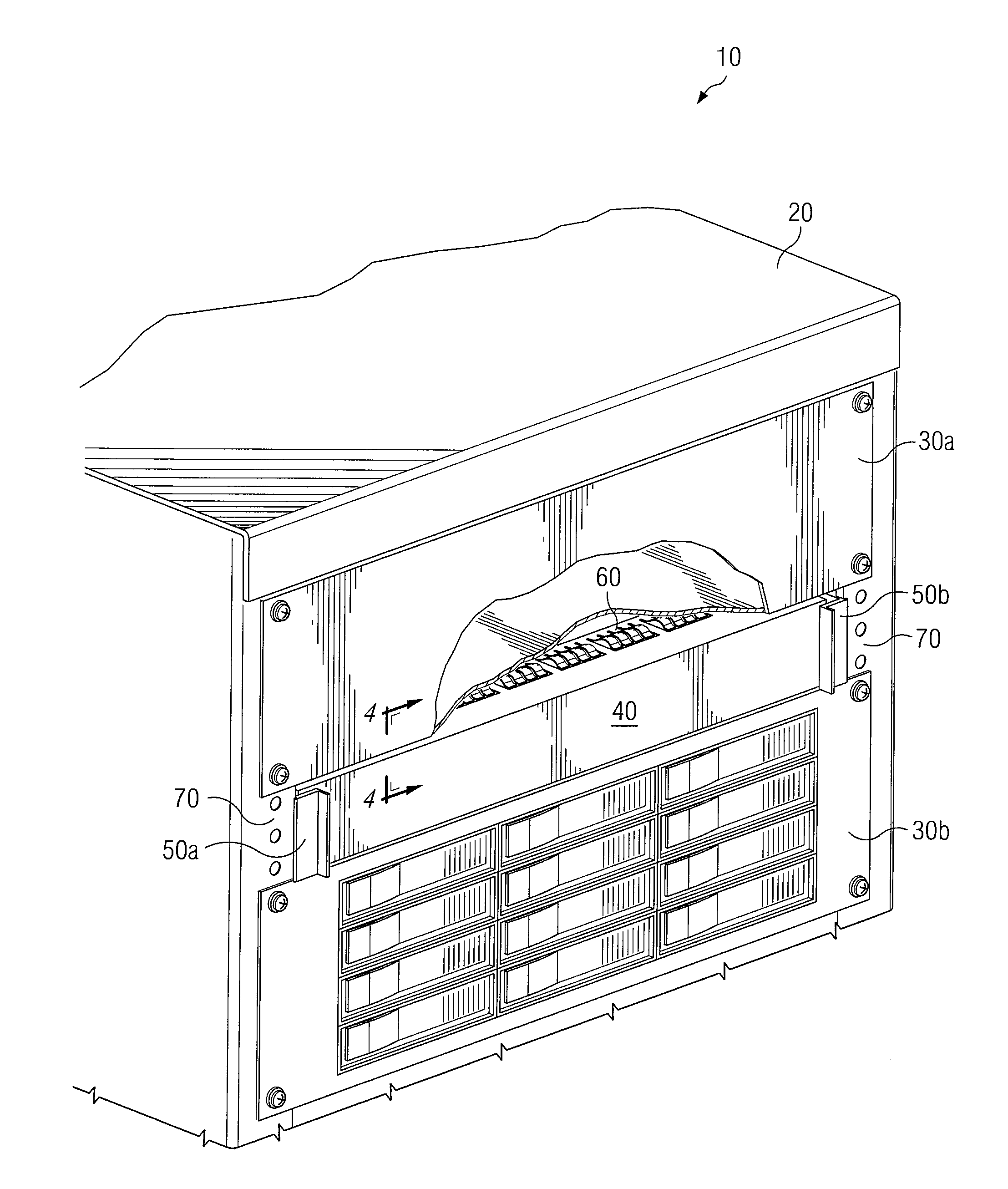

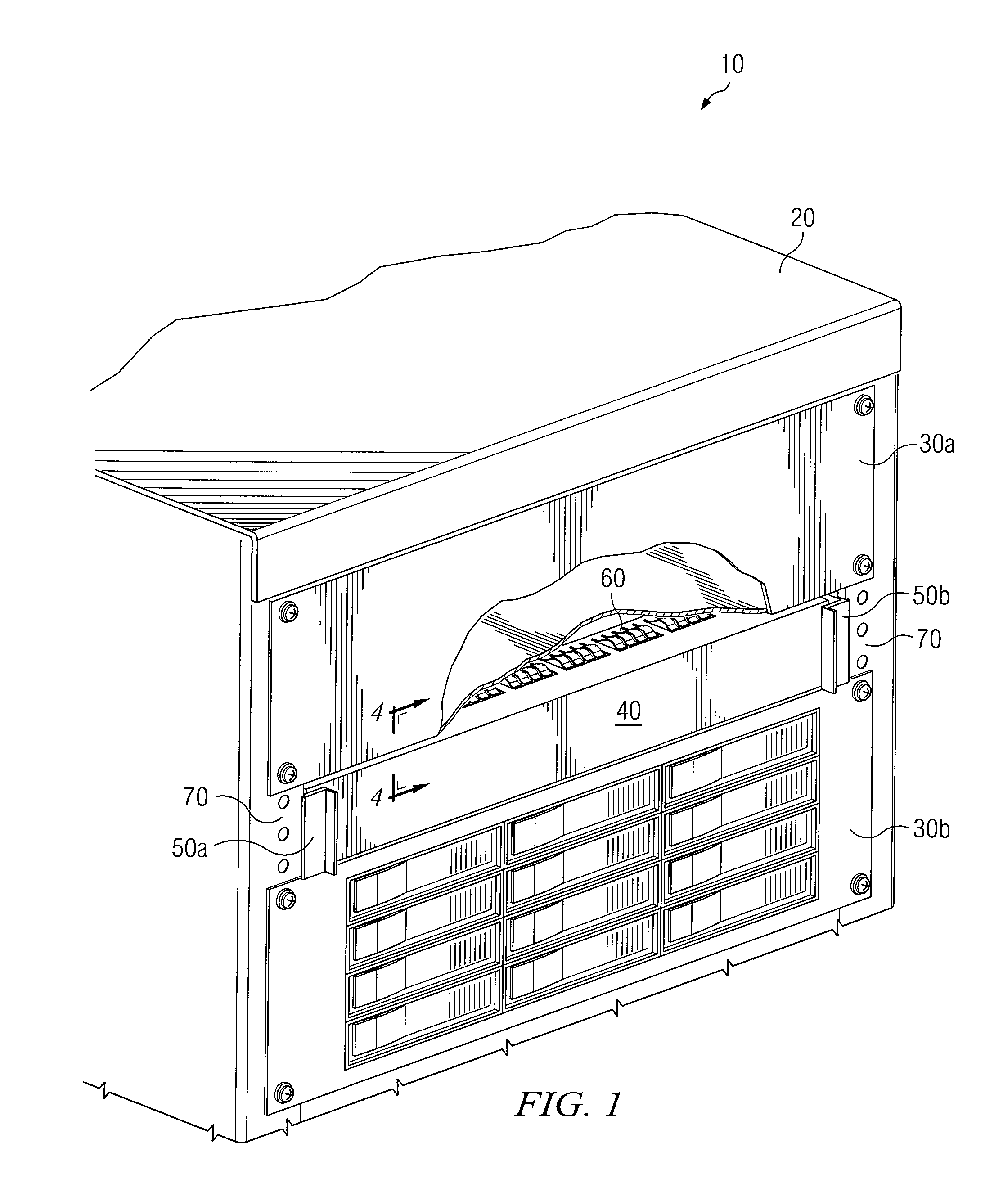

[0012]FIG. 1 illustrates a particular embodiment of a system 10 for using electrically-conductive plastic gaskets to contain electromagnetic radiation in an electrical chassis or cabinet. System 10 includes a housing 20, one or more components 30, a base unit 40, one or more latches 50, gaskets 60, and frame 70. To facilitate the containment of electromagnetic radiation radiated from certain elements of system 10 or the shielding of elements of system 10 from external electromagnetic radiation, gaskets 60, attached to or formed on one or more base units 40 mounted in housing 20, contact an adjacent surface of a neighboring component 30 or base unit 40, thereby creating an electrically-conductive path between the relevant base unit 40 and the adjacent surface. Because gaskets 60 are formed from electrically-conductive plastic, gaskets 60 may, in particular embodiments, be flexible. This flexibility may allow gaskets 60 to bridge gaps of various sizes between base units 30 and adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com