Light emission device and display device using the same

a technology of light emission device and display device, which is applied in the manufacture of electric discharge tubes/lamps, electric discharge tubes, cold cathodes, etc., can solve the problems of inefficient electric field generated between the gate electrode and the cathode electrode, and achieve the effect of improving electron emission characteristics, efficient generating electric fields, and increasing electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

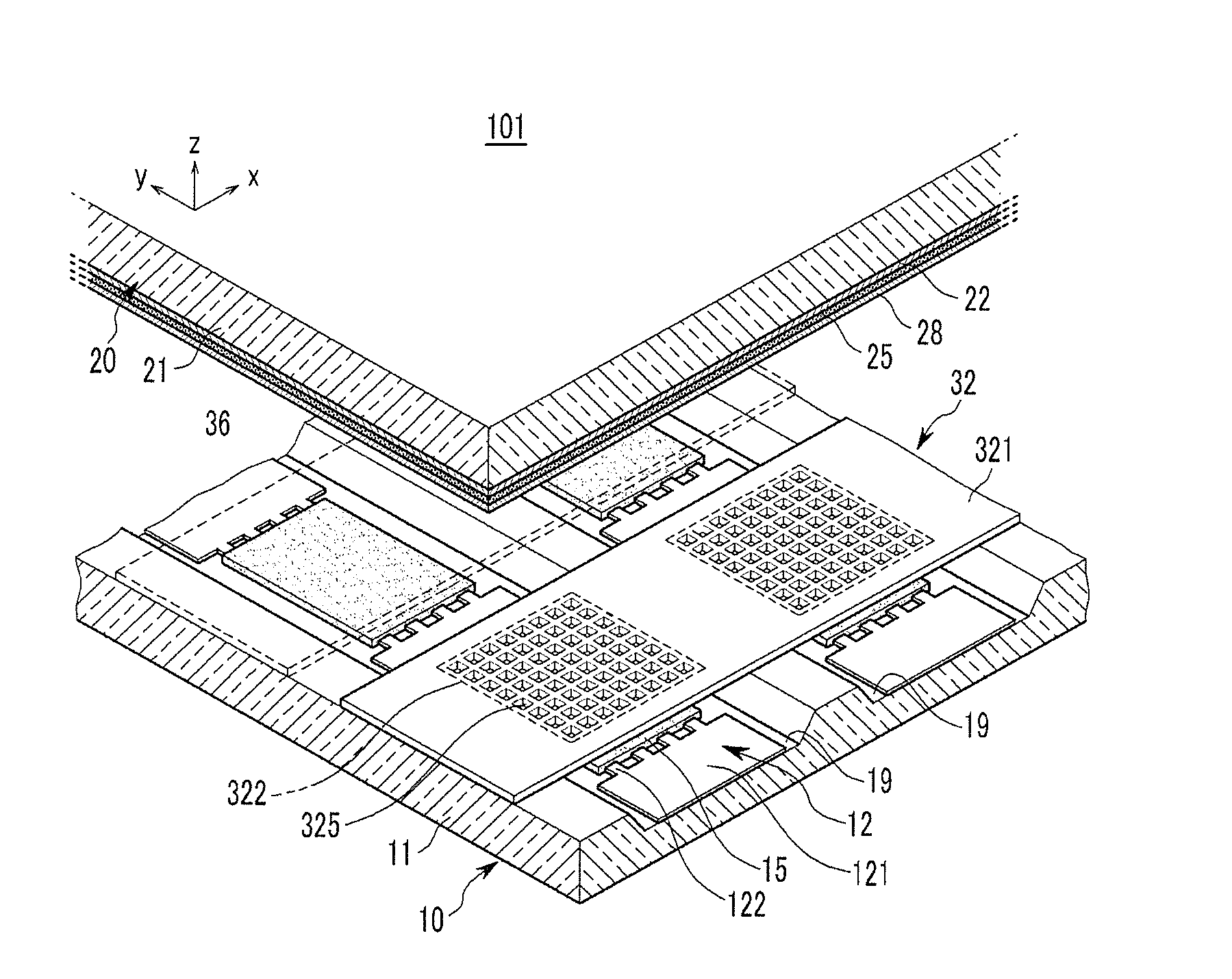

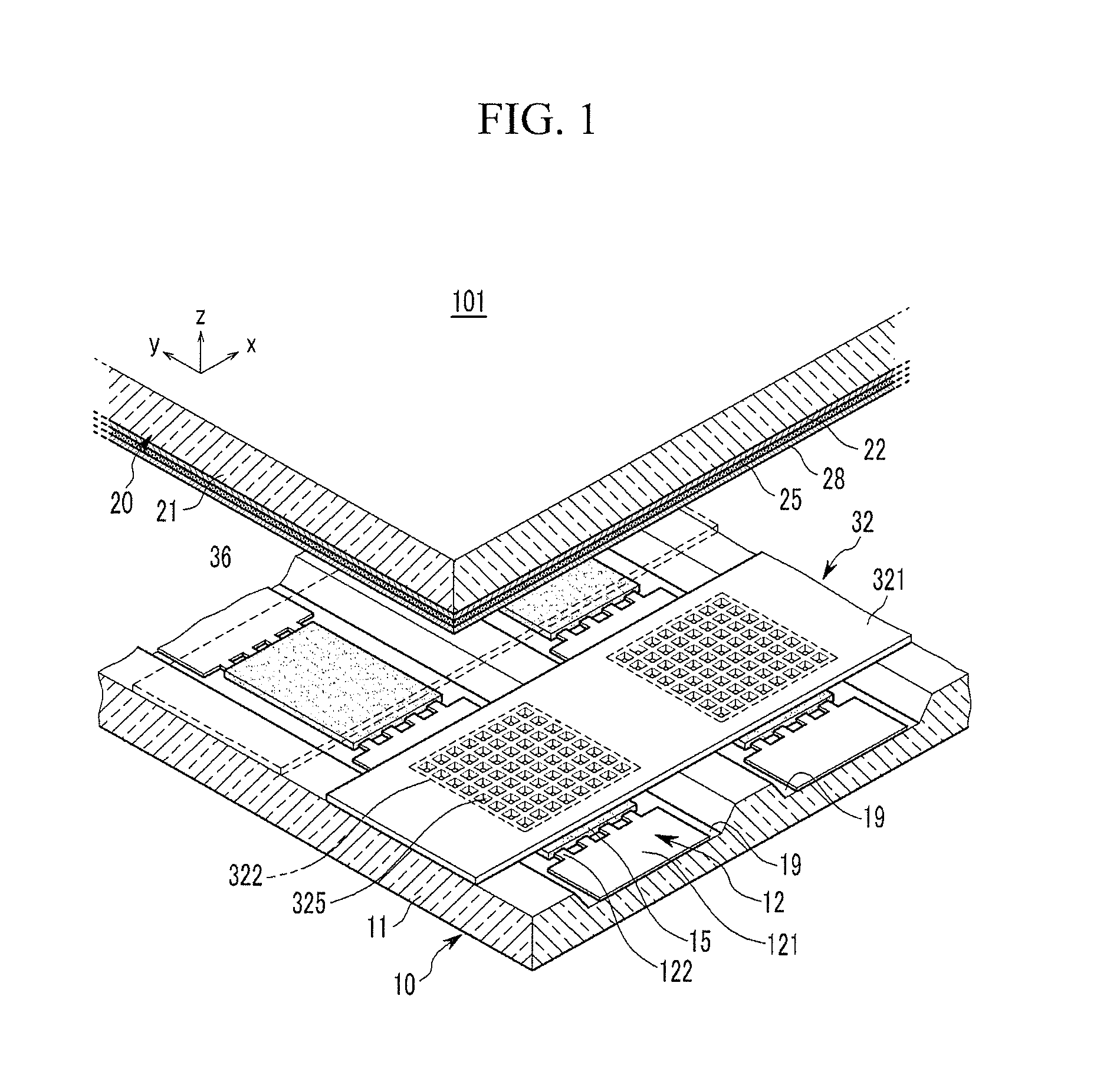

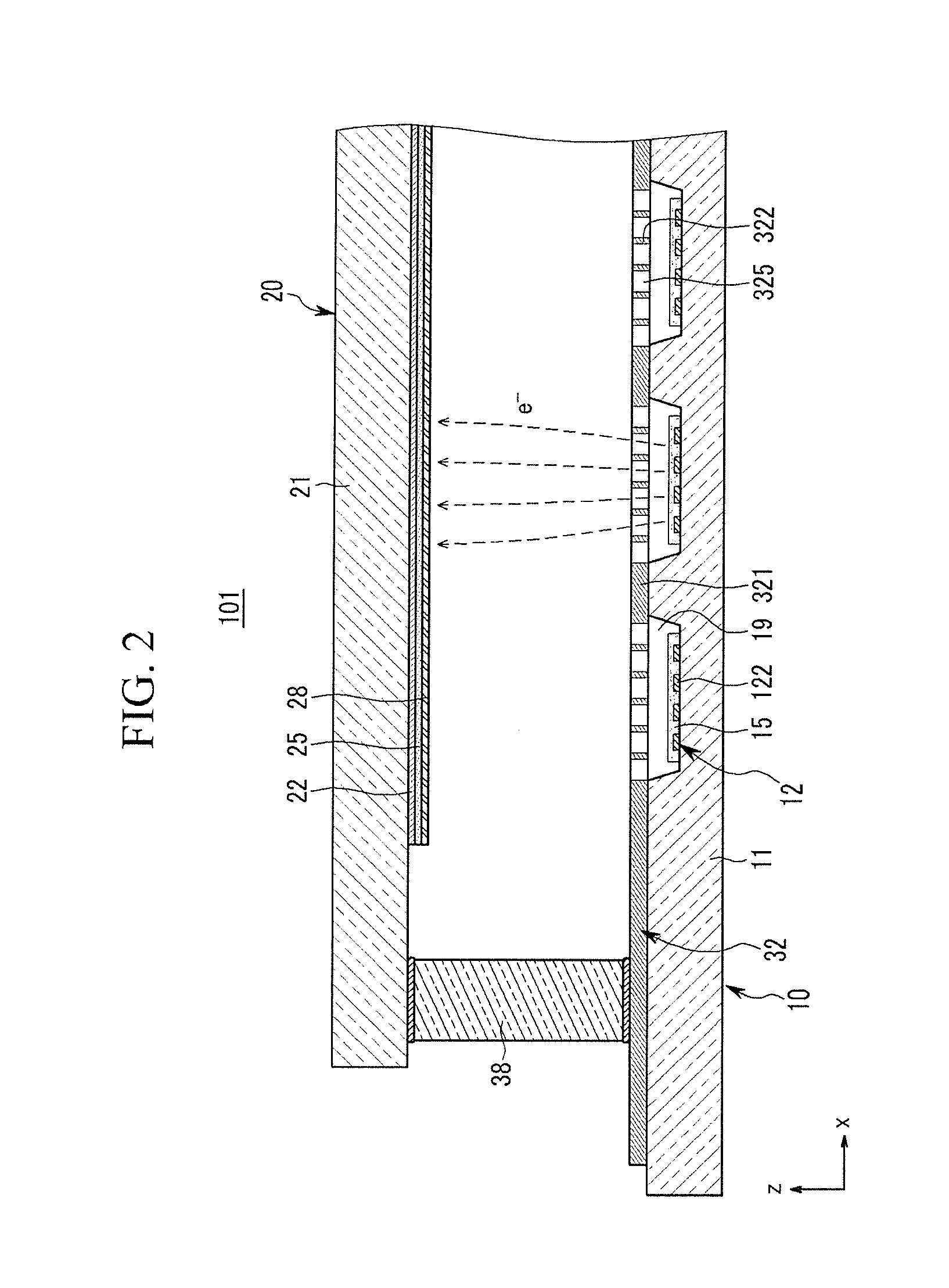

[0035]Hereinafter, referring to FIGS. 1 to 3, a light emission device 101 will be described.

[0036]As shown in FIG. 1, the light emission device 101 includes a first substrate assembly 10, a second substrate assembly 20 facing the first substrate assembly 10, and a sealing member 38 (shown in FIG. 2) that is disposed at edges (edge portions) of the first substrate assembly 10 and the second substrate assembly 20 to bond and seal the two substrate assemblies 10 and 20 to each other. The inner space formed by the first substrate assembly 10, the second substrate assembly 20, and the sealing member 38 is evacuated to be in a vacuum state maintained at a vacuum degree of about 10−6 Torr.

[0037]The first substrate assembly 10 includes a substrate or substrate body (hereinafter, referred to as “first substrate body 11”), a first electrode 12, an electron emission unit (emission region) 15, and a second electrode 32. Here, the first electrode 12 is a cathode electrode (cathode) and the seco...

second embodiment

[0066]Hereinafter, referring to FIG. 4, a light emission device will be described.

[0067]As shown in FIG. 4, in the second embodiment, a first electrode 13 of the light emission device includes (or only includes) single line parts 131 positioned at both ends of the first electrode 13, respectively, and a branch line part 132 connecting both single line parts 131. Further, in one embodiment, an electron emission unit 16 formed just above the branch line part 132 of the first electrode 13 is formed to have a stripe pattern to extend along the branch line part 132 of the first electrode 13 such that the electron emission unit 16 extends through a region crossing the second electrode 32 (shown in FIG. 1) and regions not crossing the second electrode 32.

[0068]By this configuration, the light emission device 101 can further facilitate a process of arranging the first electrode 13 and the second electrode 32 with each other (without an extra alignment) while increasing or maximizing emissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com