Rapid compressor cycling

a compressor and speed technology, applied in the direction of refrigeration safety arrangement, refrigeration components, light and heating equipment, etc., can solve the problem of not allowing the refrigerant system to respond to the effect of cycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

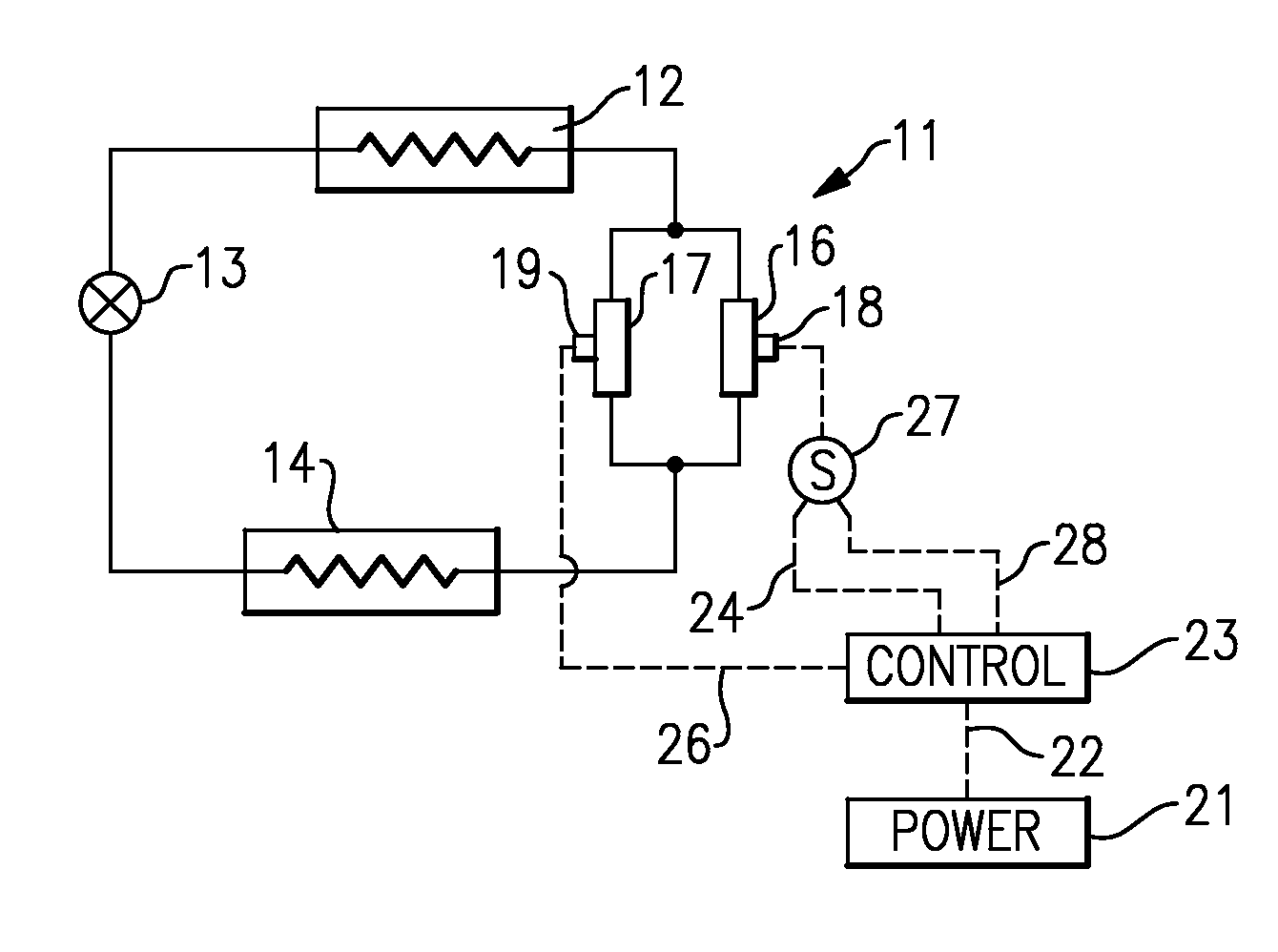

[0015]Shown in FIG. 1 is a basic vapor compression system which includes a compressor assembly 11 a heat rejection heat exchanger (a condenser or a gas cooler) 12, an expansion device 13 and an evaporator 14. In a conventional manner, the refrigerant vapor is compressed in the compressor assembly after which it passes to the heat rejection heat exchanger 12 where the heat is transferred from the refrigerant to a secondary loop fluid such as air, water or glycol. The refrigerant is expanded in the expansion device 13, and the expanded refrigerant that is at lower pressure and temperature then passes to the evaporator 14 where it assimilates heat from an environment, with the resultant refrigerant vapor then passing back to the compressor assembly 11.

[0016]The compressor assembly 11 as shown comprises a pair of compressors 16 and 17 operating in parallel or a so-called tandem configuration. In this regard, it should be understood that the present invention is equally applicable to use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com