Foam-concrete rebar tie

a technology of foam-concrete rebar and rebar ties, which is applied in the direction of building reinforcements, constructions, building components, etc., can solve the problems of poor tension of concrete and prior art failure to present a proper system, apparatus and method for properly positioning and orienting rebar at a proper position, so as to prevent rotational and longitudinal movement and add rigidity to the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]This application claims priority to U.S. patent application Ser. No. 12 / 047,036 filed Mar. 12, 2008.

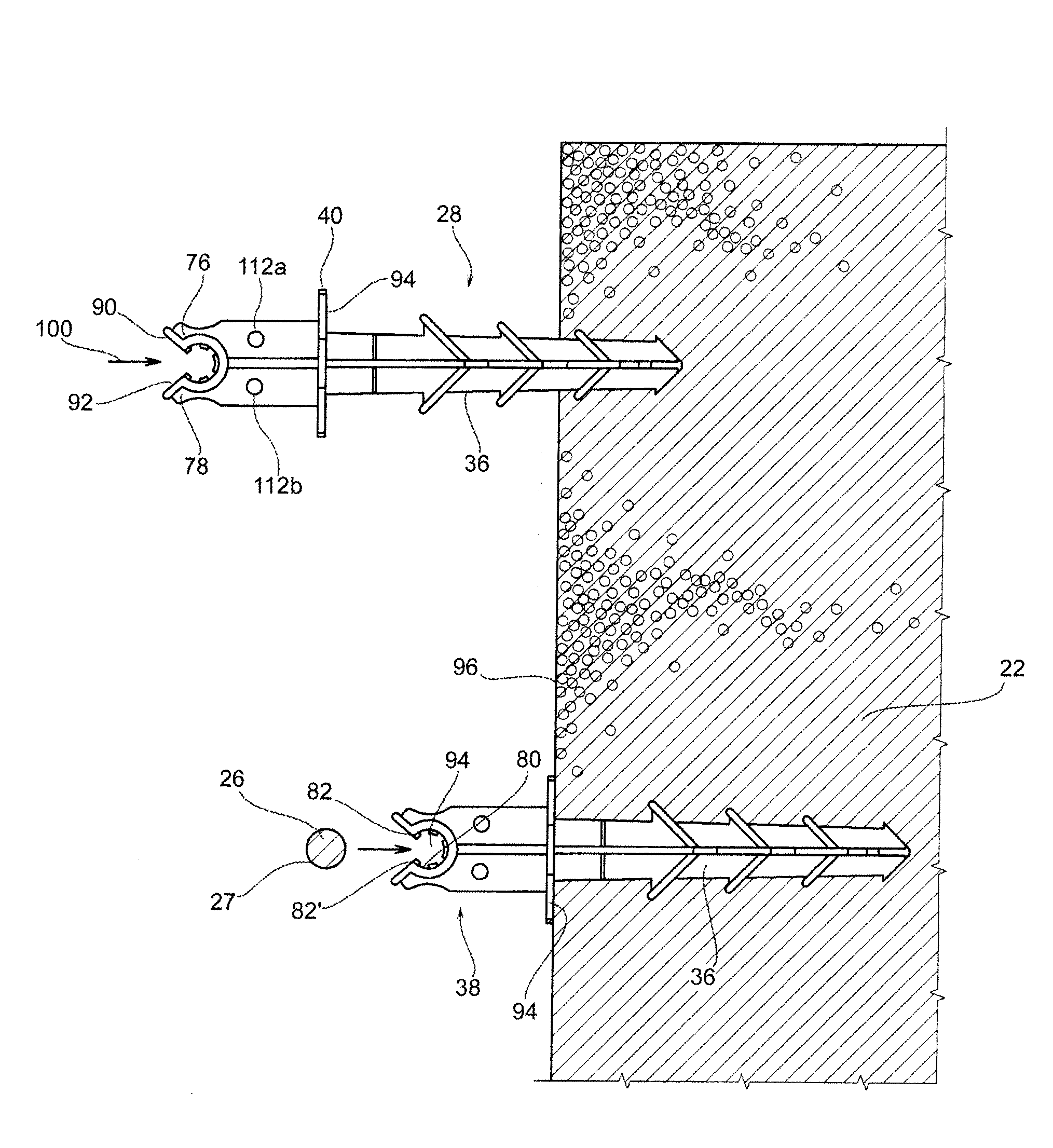

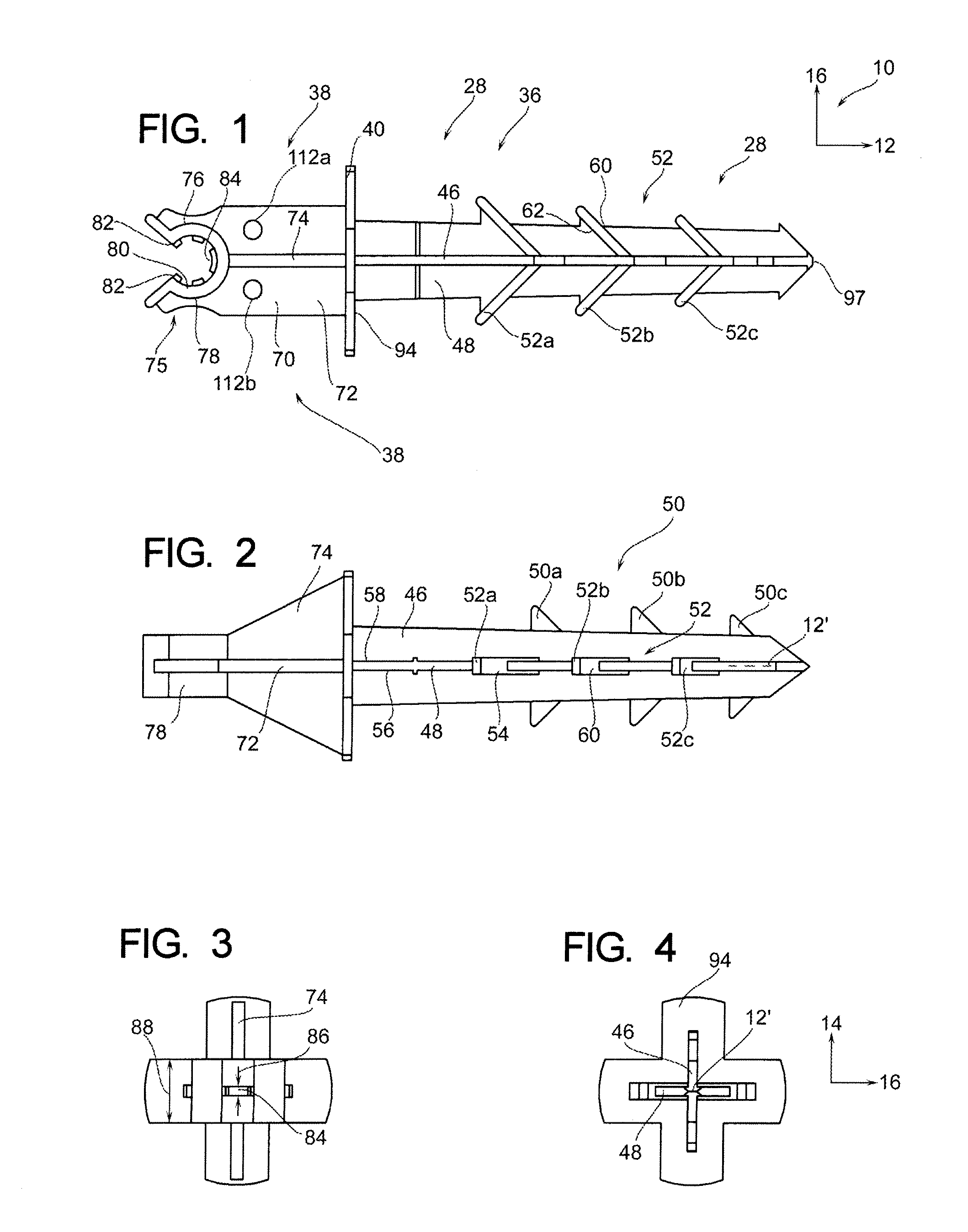

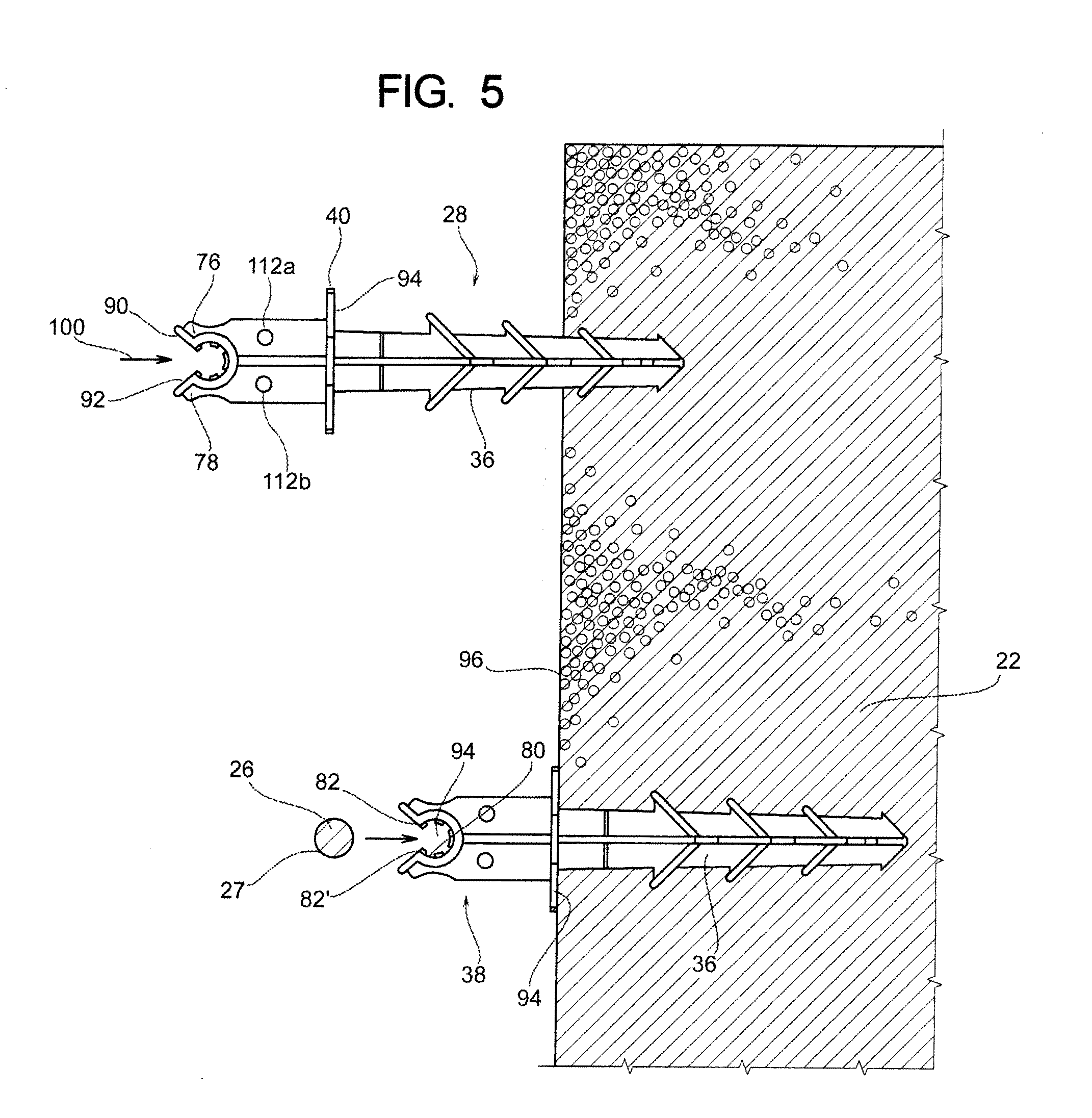

[0022]As shown in FIG. 7, there is an environmental view of a foam concrete structure 20. In general, the foam concrete structure 20 comprises a foam material 22 and a concrete portion 24. Further comprising the foam concrete structure 20 are tensile stress members such as rebar 26 and rebar-holding members 28. Further, in one form of manufacture, an outer mold member 30 can be utilized to hold the concrete 24 in its position while in an uncured state. This outer mold member 30 can either be a part of the veneer of the structure, or be removed from the concrete perimeter 24 once the concrete cures or otherwise is sufficiently rigid to hold its stationary form.

[0023]Therefore, it can be appreciated that the tensile stress member 26, which is most commonly rebar at the time of this writing, is positioned at a substantially center region 32 within the concrete perimeter 24. This po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com