Heat Exchange Assembly and Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

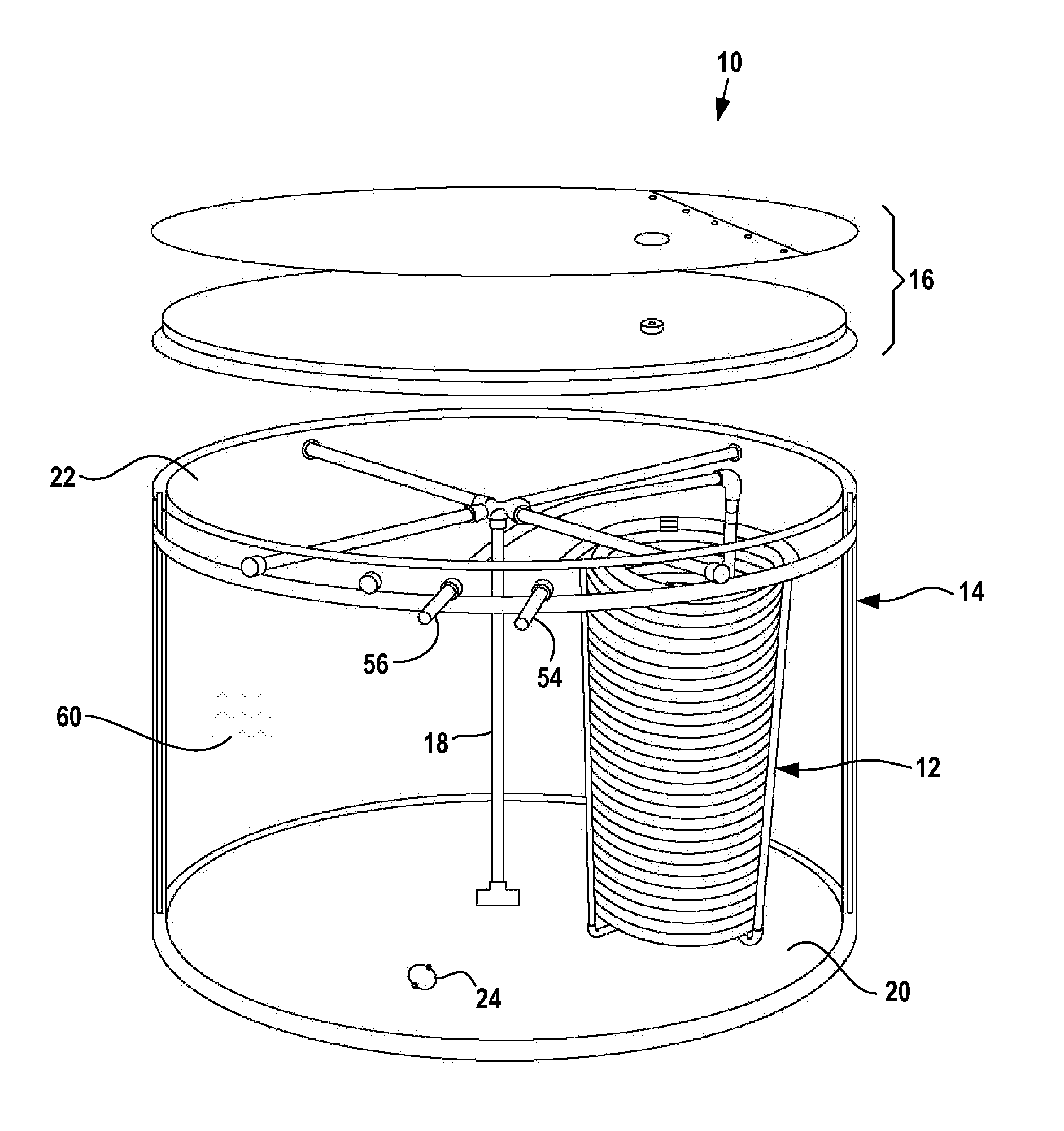

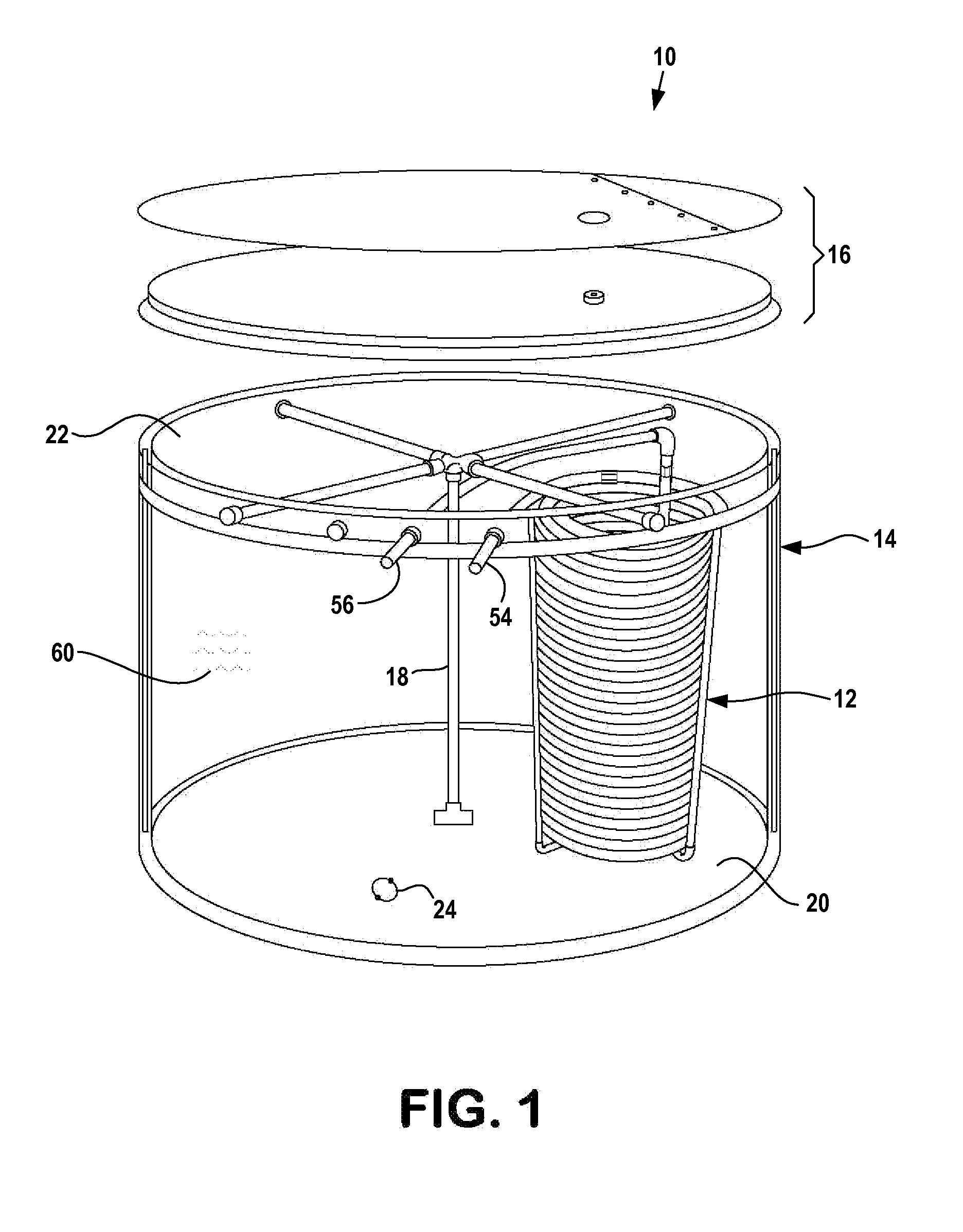

[0021]Heat exchange assembly 10 includes heat exchanger 12 installed in tank 14. Tank 14 may be a conventional insulated water tank having a lid 16 and a brace 18. Brace 18 supports lid 16 when the lid is placed on the tank. Brace 18 extends upward from tank bottom 20 to tank top 22. Drain 24 is located at tank bottom 20 to allow draining tank 14.

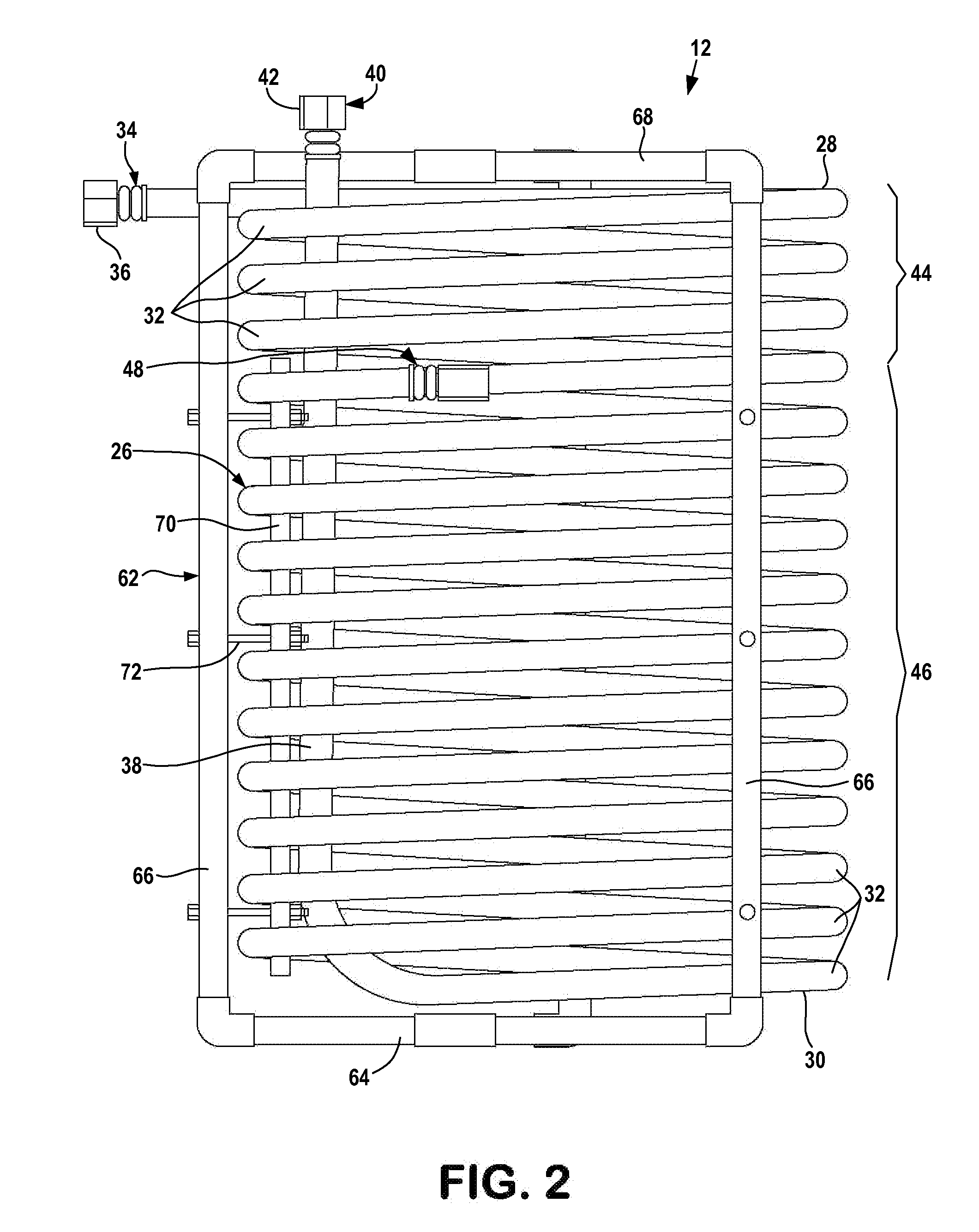

[0022]Heat exchanger 12 is made up of an elongate coiled tube 26 extending generally axially from exchanger top 28 to exchanger bottom 30. Tube 26 forms a number of circular coiled loops 32 that extend from exchanger top 28 to exchanger bottom 30. Tube first end 34 is located at exchanger top 28 and includes a fitting 36. Fitting 36 may be a conventional female pipe threading. The bottom coiled loop 32 of tube 26 is joined to vertical output line 38. Output line 38 extends up through the center of the exchanger beyond exchanger top 28 to a tube second end 40. Tube second end 40 includes a fitting 42 which may be conventional female pipe thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com