Core assembly for winding sheet and winding method

a technology of core assembly and winding method, which is applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of high structural cost, difficult adjustment of outer diameter of the core assembly, and failure to keep high precision of the inner diameter of the sheet roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

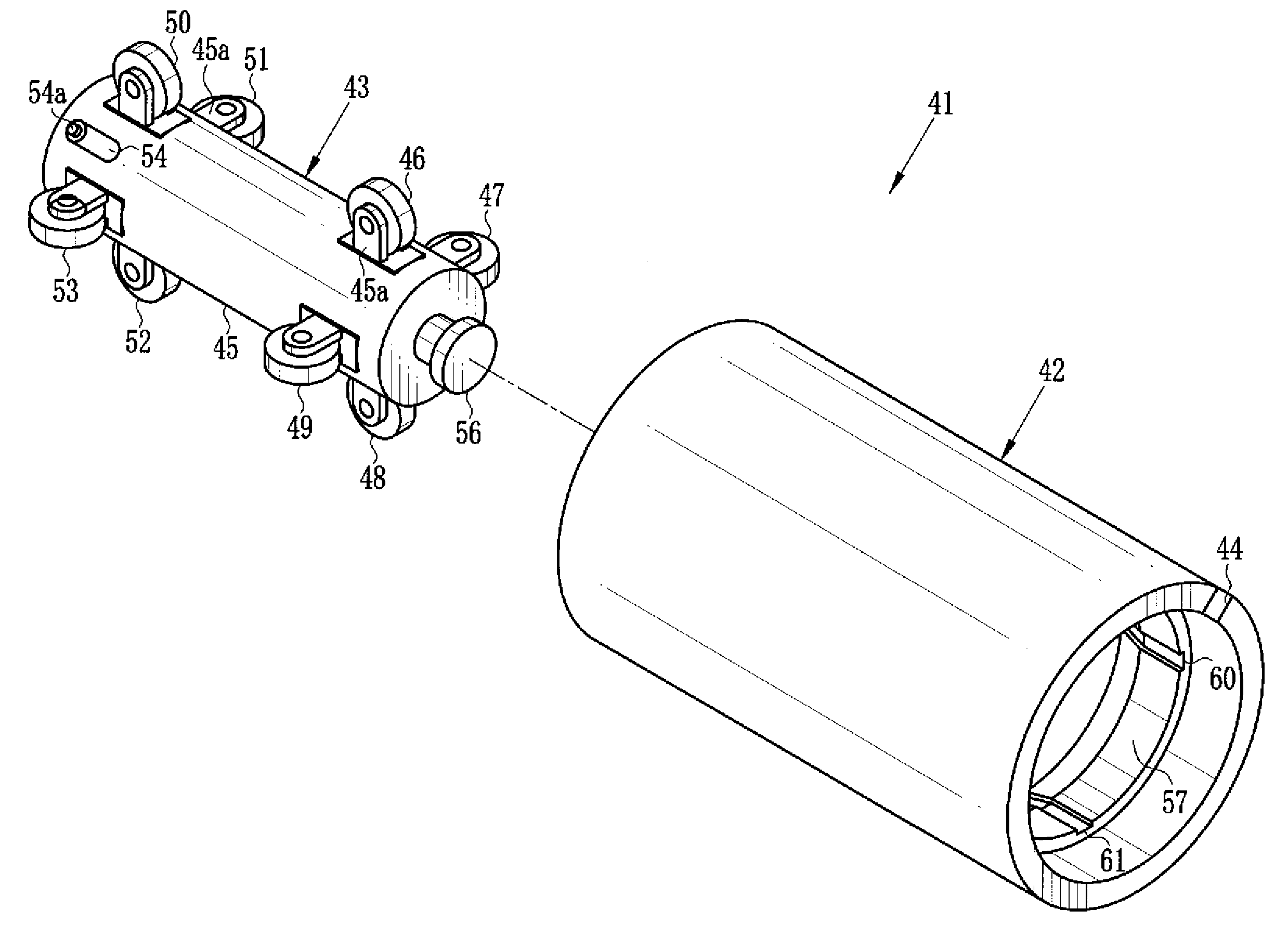

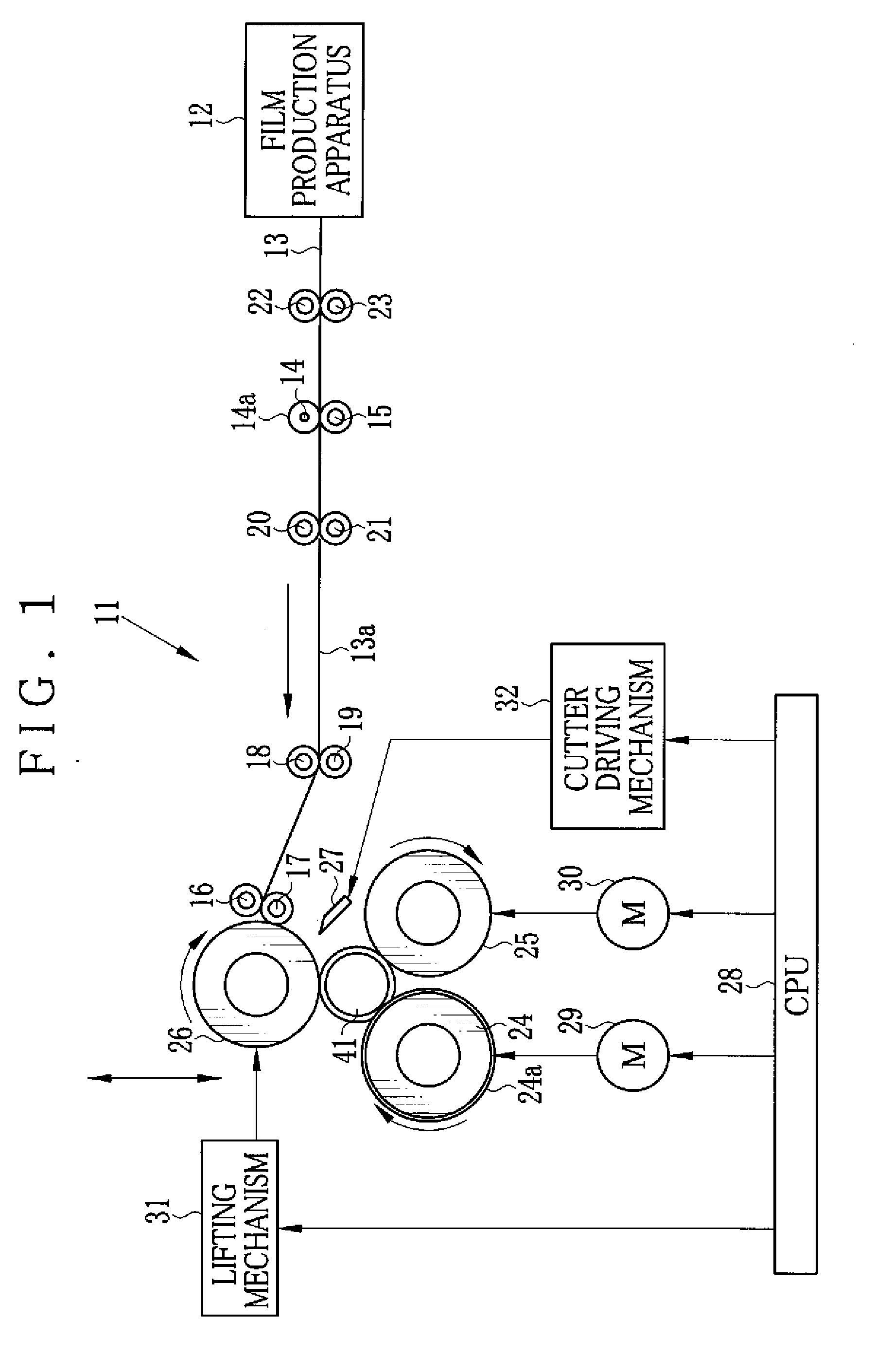

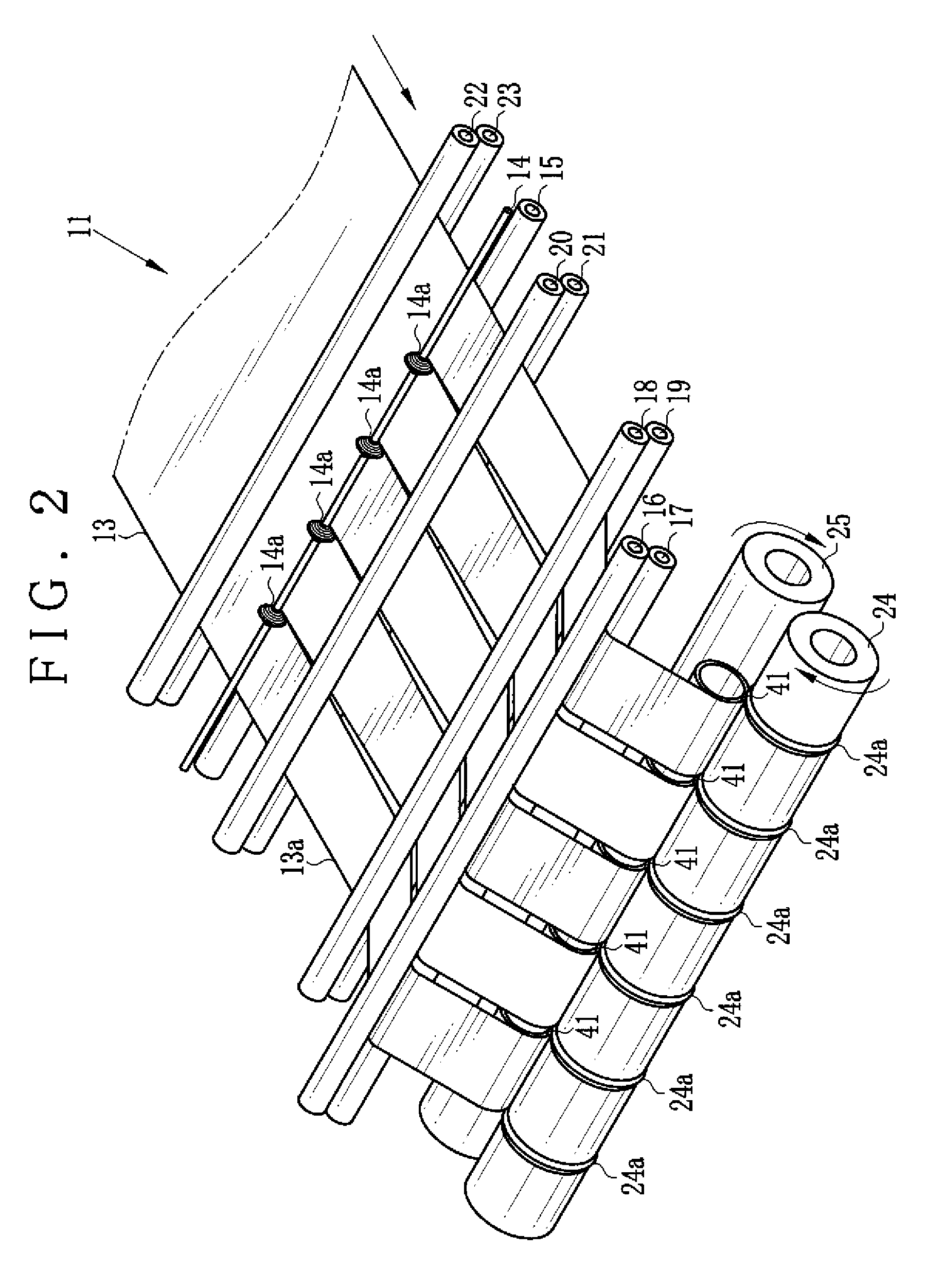

[0043]In FIGS. 1 and 2, a film winding system 11 or a film winding line is connected with a film production apparatus 12. Film web 13 is produced by the film production apparatus 12 continuously. A plurality of continuous sheets 13a or continuous film of a strip shape are formed by slitting the film web 13. In the film winding system 11, a core assembly 41 or spool assembly or a winder winds the continuous sheet 13a to obtain a sheet roll 71 or film roll. See FIG. 8.

[0044]The film winding system 11 includes a slitting roller 14, a blade receiving roller 15, guide rollers 16, 17, 18, 19, 20, 21, 22 and 23, surface rollers 24 and 25, a rider roller 26, a cutter 27, a CPU 28, motors 29 and 30, a lifting mechanism 31 and a cutter driving mechanism 32. In FIG. 2, elements are clarified in a simplified manner, so the rider roller 26, the cutter 27, the CPU 28, the motors 29 and 30, the lifting mechanism 31 and the cutter driving mechanism 32 are not illustrated.

[0045]A plurality of blades...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com