Lid-container for independent mixing and a method for its application

a lid-container and independent mixing technology, applied in the field of aseptic sealing of bottles, flasks, food, pharmacology and medicine, can solve the problems of not being able to avoid exposure to the environment, not being able to ensure reliable isolation of the contents of the vessel, and not being able to apply the known design, so as to maintain the effect of dynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Information Confirming the Possibility of Realizing the Invention:

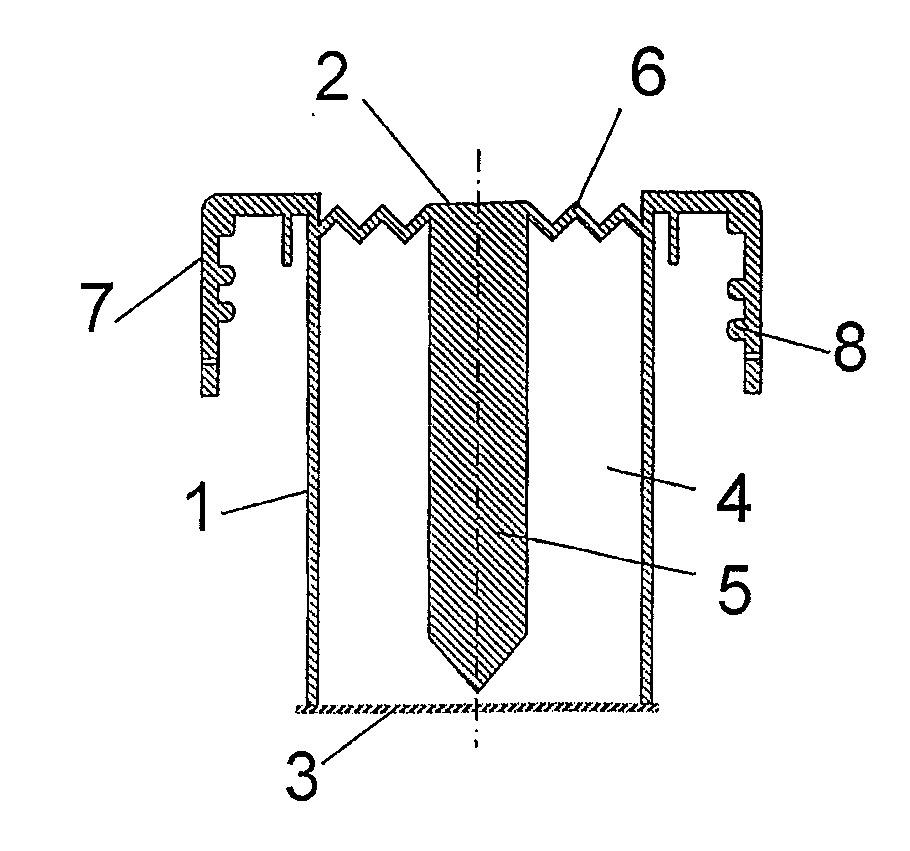

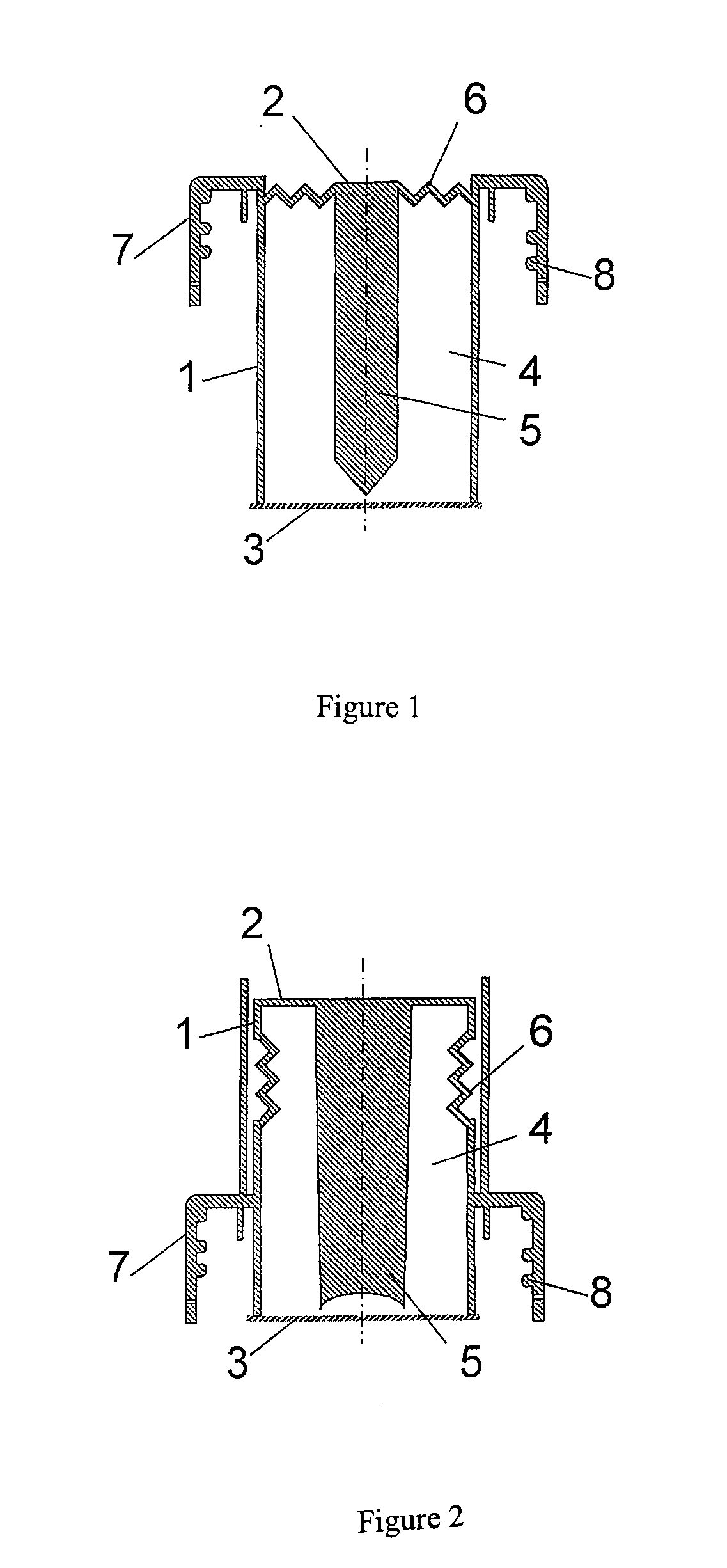

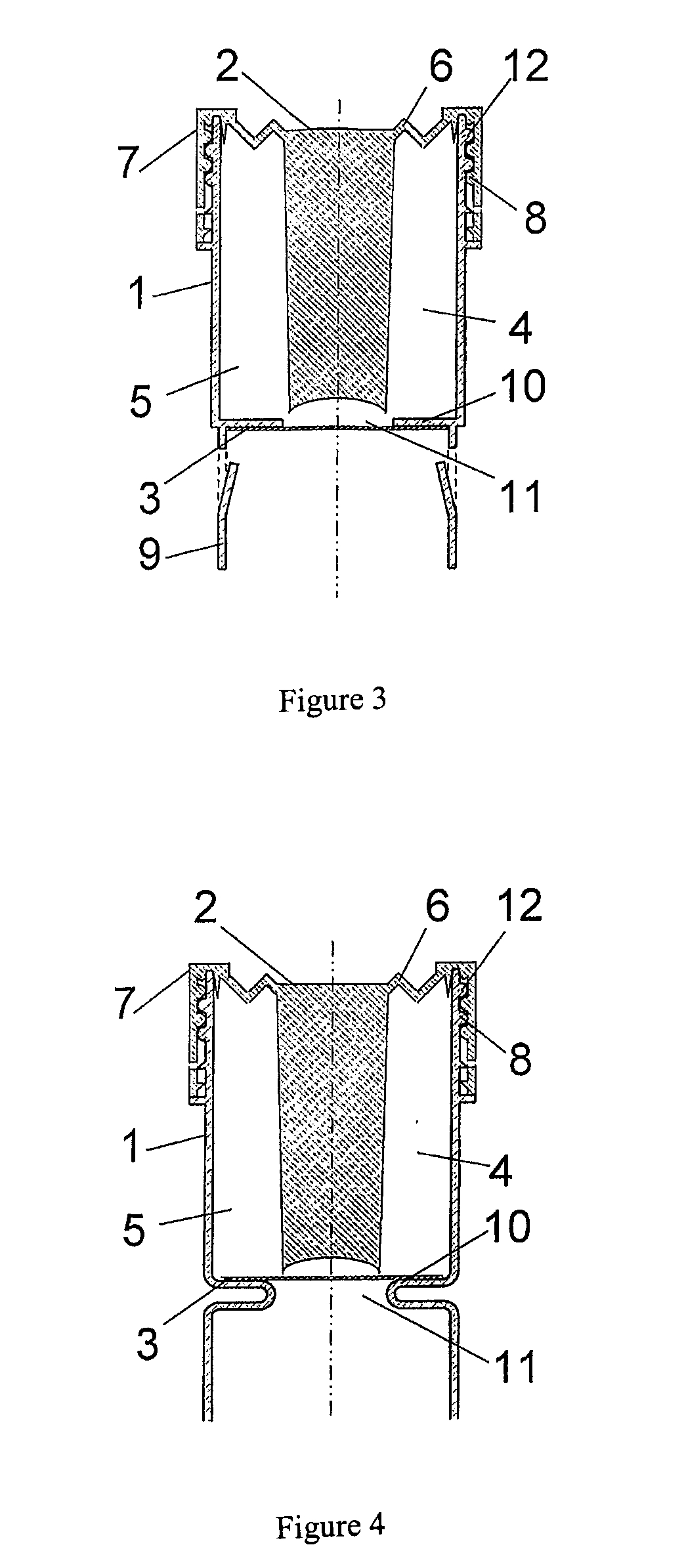

[0041]The lid-container for independent mixing comprises a body in the form of side walls 1 with a bottom 2, and a sealing plane 3, and is an integral product with a mechanism for connecting to a vessel rim. The sealing plane 3 is located in the lower end section of the side walls and made as a film 3 that is hermetically attached to the side walls 1 along the entire contour and creates an enclosed and sealed inside space 4 with an insert 5. The bottom 2 can have corrugation 6 or the side walls 1 can have corrugation 6. The bottom 2 and the side walls 1 can have corrugation 6 separately or together. In any of the embodiments, between the bottom and the sealing film 3, there is an insert 5 which interacts with the bottom 2, and there is a circular shell 7 with a female thread 8 attached to the side walls , for attachment to a vessel neck rim.

[0042]In addition, one embodiment of the lid-container installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com