Material supply for a tablet pressing machine, a tablet pressing machine and a cleaning method for a tablet pressing machine

a tablet pressing machine and cleaning method technology, applied in the field of tablet pressing machines, can solve the problems of limited development of material supplies for generic tablet pressing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

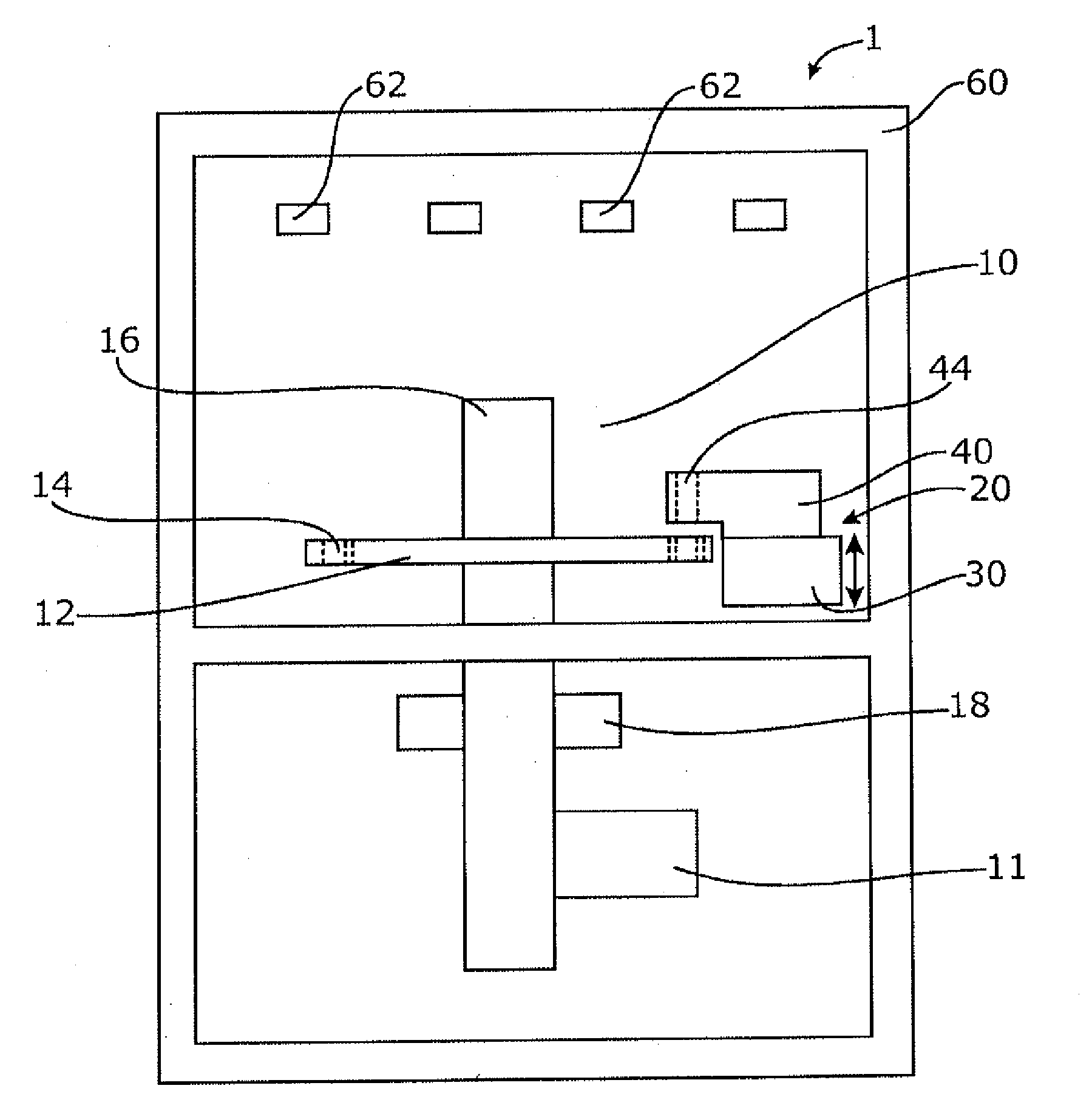

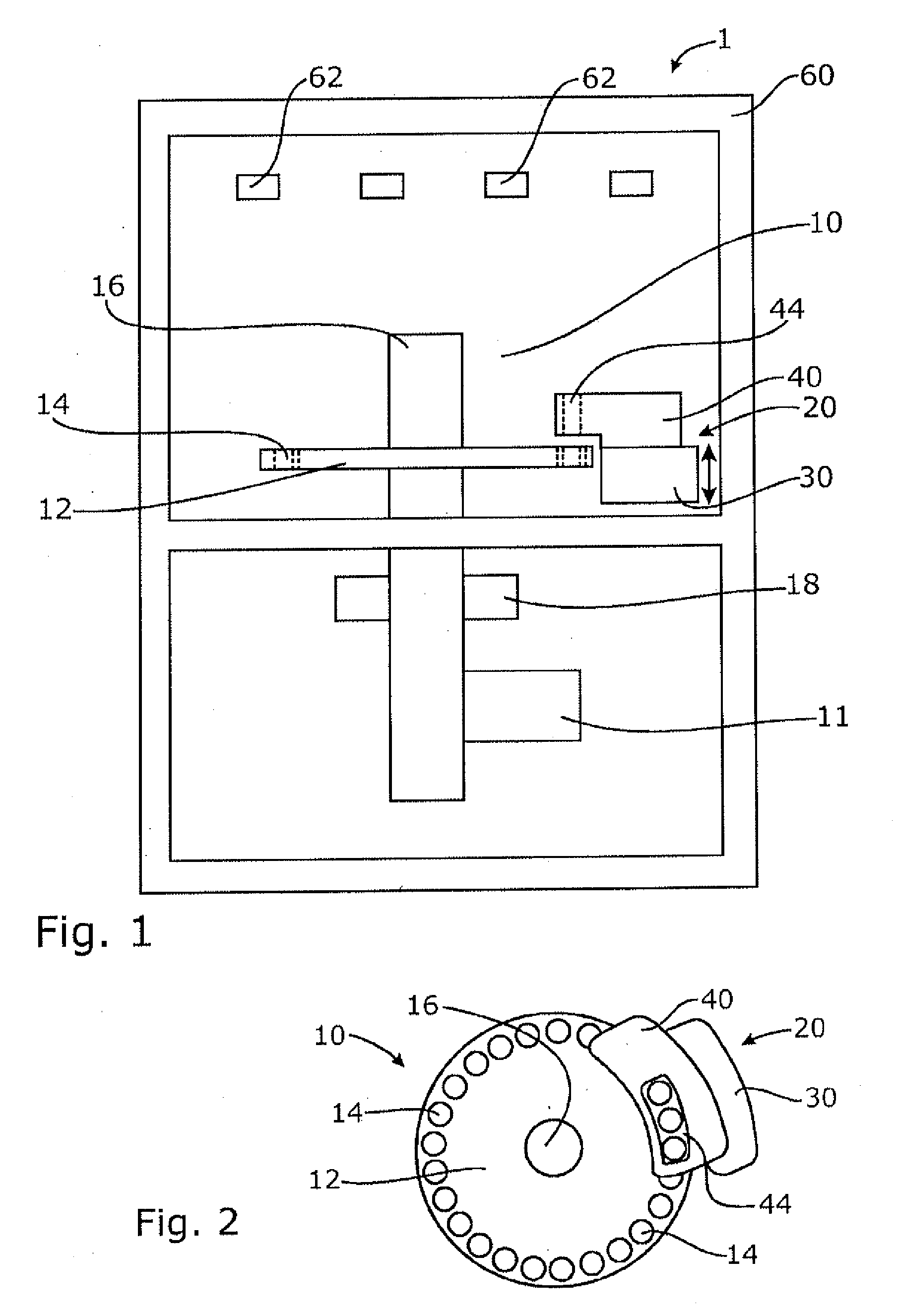

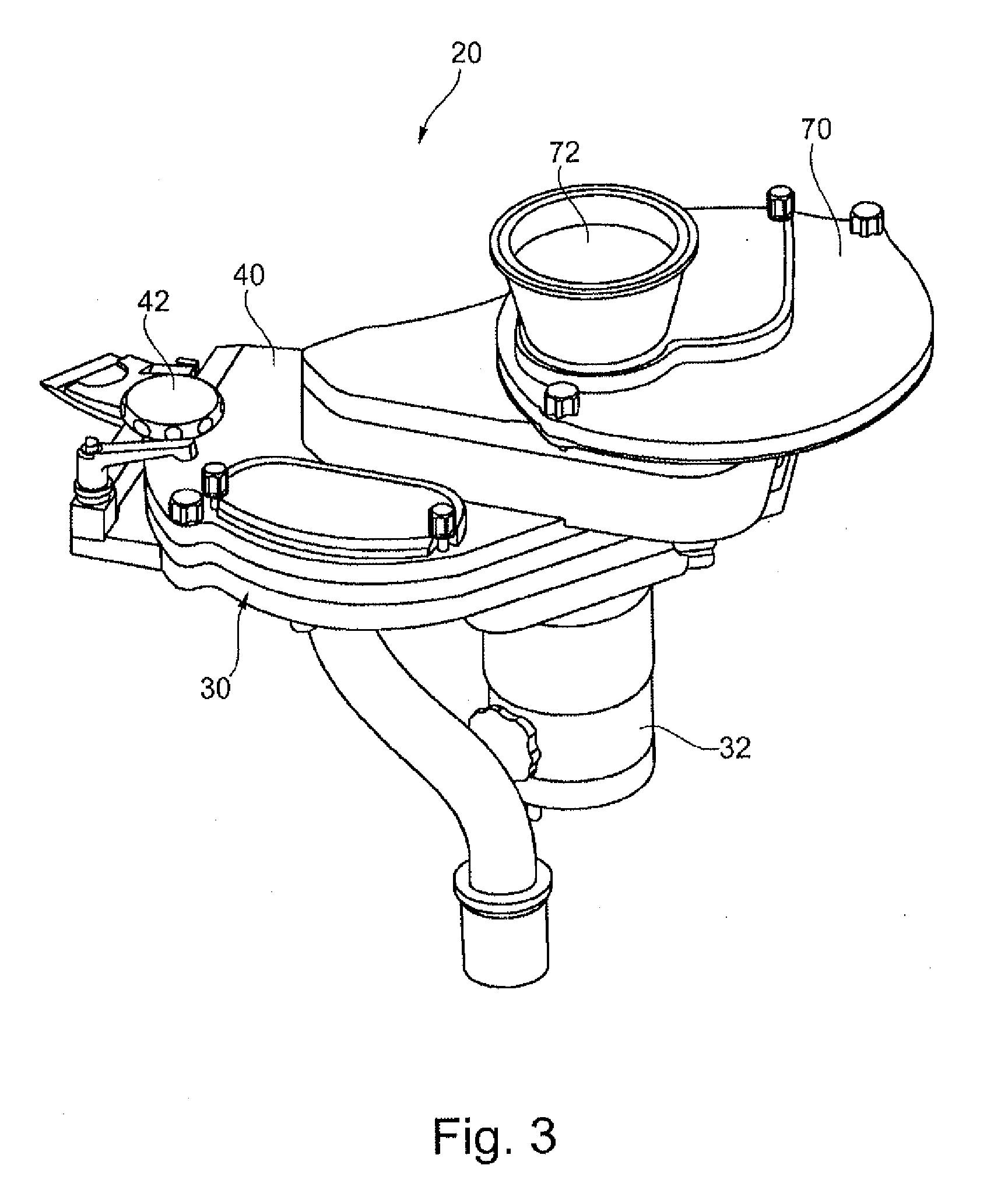

[0036]A tablet pressing machine 1 according to the invention can be seen from FIG. 1 in a simplified sectional illustration. The tablet pressing machine 1 has a rotor 10 which comprises a spindle 16 which is rotatably mounted in a bearing 18 in the frame 64 of the tablet pressing machine 1. The frame 64 can consist for example of a tube frame which gives the tablet pressing machine 1 the necessary mechanical stability. In addition, the rotor 10 comprises a matrix disc 2 in which a plurality of matrices 14 are arranged, spaced equally apart. Here, the matrices 14 can be formed directly as a recess in the matrix disc 12, but they may also be constructed as separate parts which are inserted into recesses, constructed in a complementary manner, in the matrix disc 12 (as illustrated). The matrix disc 12 is preferably formed in a single piece, but it is also readily possible to use matrix discs which are formed in several parts. The spindle 16 of the rotor 10 is driven by means of a motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com