Rankine cycle system

a cycle system and cycle technology, applied in steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of large amounts of waste heat simply dumped into the atmosphere, oxides and particulates may be emitted, and conventional heat recovery systems do not operate with sufficient efficiency to make energy recovery cost-effective,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

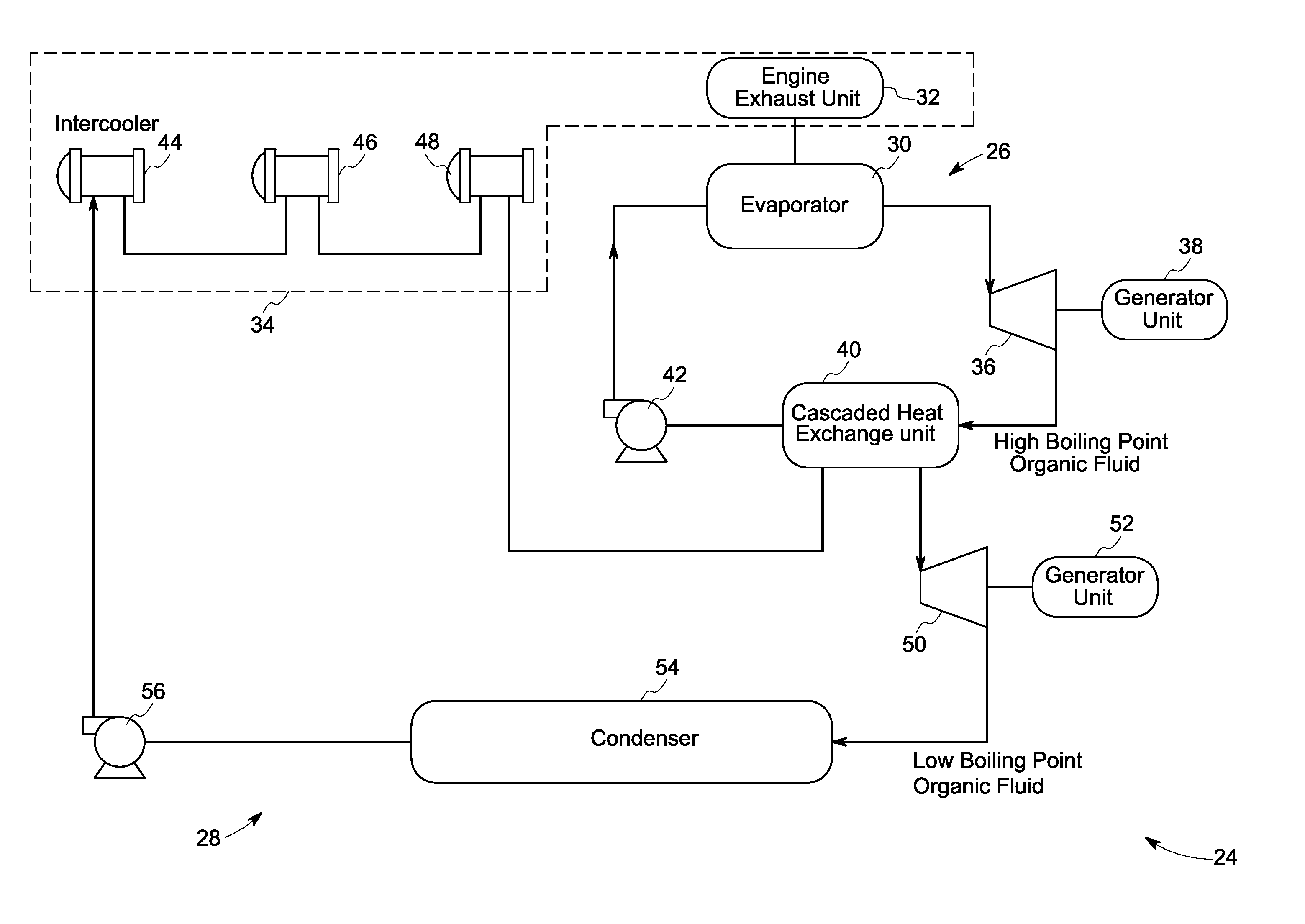

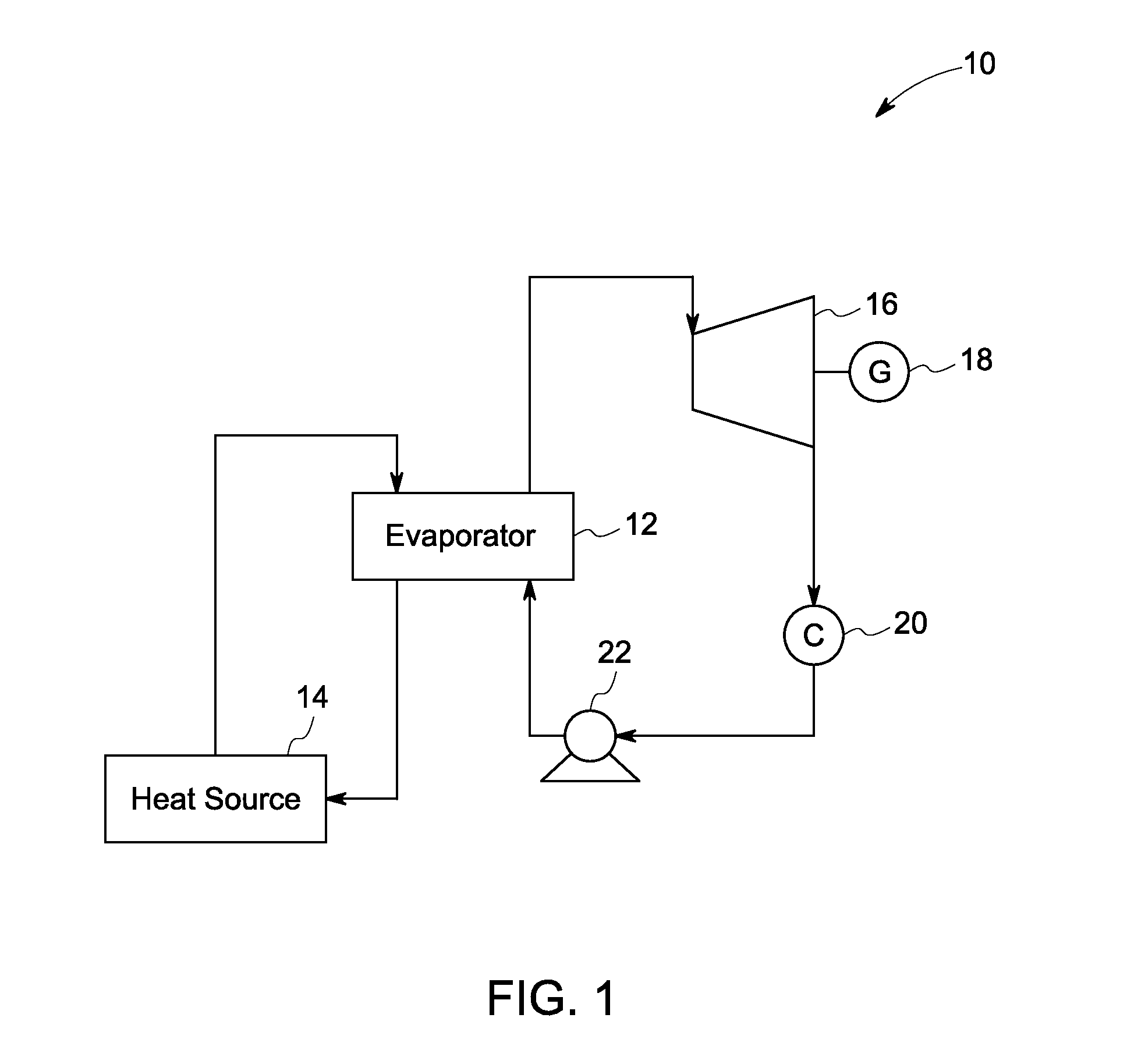

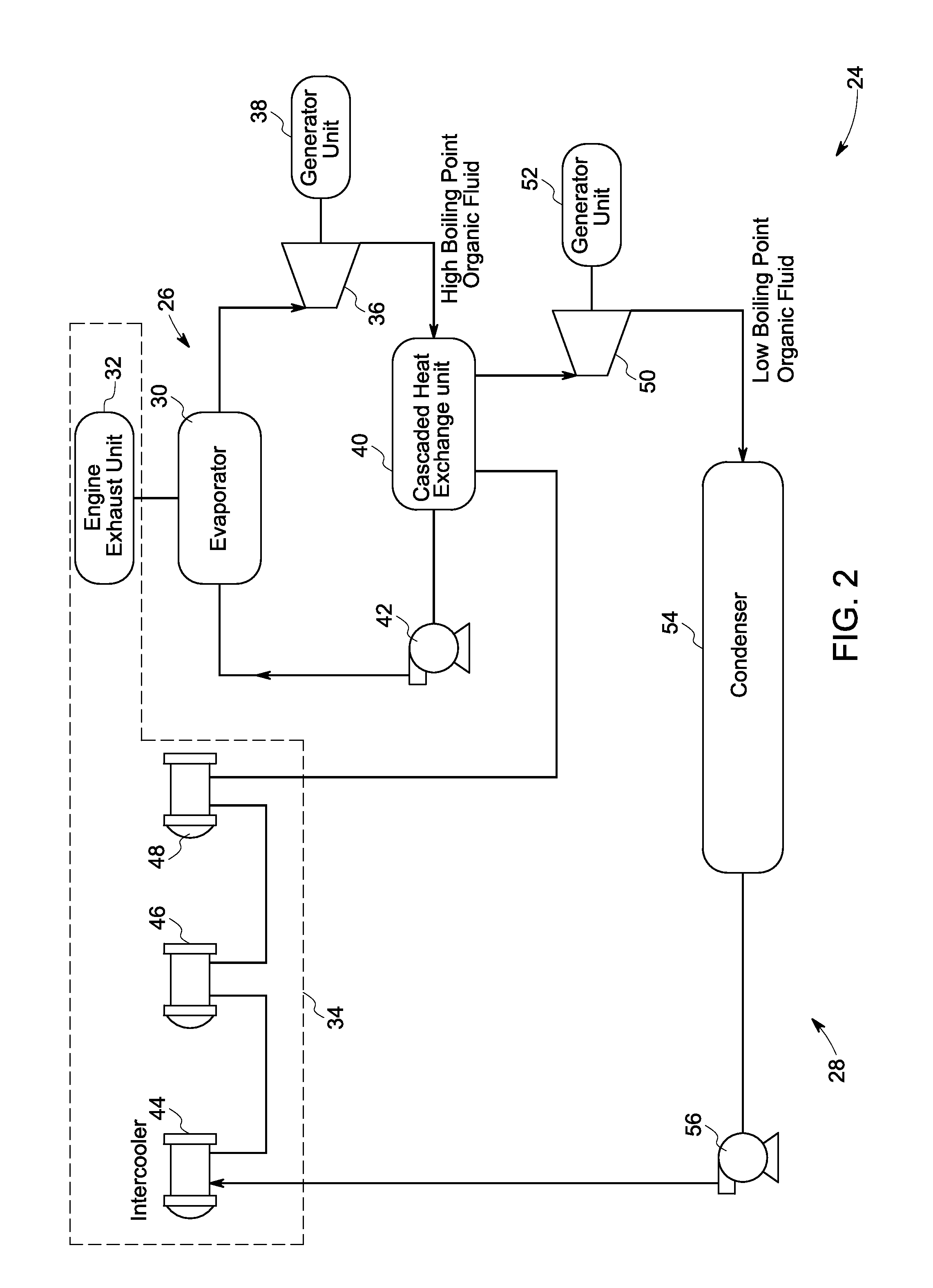

[0014]In accordance with the exemplary embodiments of the present invention, a rankine cycle system is disclosed. The rankine cycle system includes an evaporator coupled to a heat source and configured to circulate a working fluid in heat exchange relationship with a hot fluid from the heat source so as to heat the working fluid and vaporize the working fluid. An expander is coupled to the evaporator and configured to expand the vaporized working fluid from the evaporator. The exemplary expander is operable at variable speed. A condenser is coupled to the expander and configured to condense the vaporized working fluid from the expander. A pump is coupled to the condenser and configured to feed the condensed working fluid from the condenser to the evaporator. In accordance with a specific embodiment of the present invention, a waste heat recovery system including at least two integrated rankine cycle systems having an expander operable at variable speed is disclosed.

[0015]Referring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com