Studies have shown a

high rate of error in such documents.

However, although the recipient of a generated certification document has the control statements for the product, he is not able to obtain or validate the

source document supporting a control statement in an automatic way.

Nor can the recipient automatically determine whether a change relevant to a control statement in the received certification document might have occurred from the time of the document's creation.

Moreover, the recipient may wish to use the product in a different market or area of the world, and is unable to relate the control statements relevant in one jurisdiction to parameters of use in other jurisdictions or areas.

The customer may receive a certification document with control statements that depend upon the specific claims of an upstream manufacturer of raw materials used by the immediate supplier of the customer; however, the upstream manufacturer may be unwilling to disclose important source information to the immediate supplier without a non-disclosure agreement, because of claims of

confidentiality or trade secrecy.

In consequence, the control statements made in the safety data sheets reviewed in the study have deficiencies that may include missing control statements, out-of-date control statements, or other errors.

A number of studies agree: Error rates in supplier certification statements are high.

Nevertheless frequent reports appear where a food processor has purchased a material that contains a contaminant not reviewed adequately.

The

probability of error between supplier and customer increases with the volume of certification documents and the number of suppliers.

It is true that the supplier may have proprietary evidence to support a certification and may not have revealed the full composition of a formulation under restrictions on the disclosure of confidential business information, in which case an independent evaluation is limited.

Such ad hoc customer procurement standards that are in addition to any mandatory governmental requirement and accepted only in the face of market pressure have become widely accepted in part because of the difficulties and high error rates in certification documents being passed in the supply chain between supplier and customer.

In addition, these standards are subject to change without notice.

Such ad hoc standards increase the cost of compliance and its complexity, and reflect the need for an

improved method of producing, distributing, and validating certification documents in the supply chain.

Today, suppliers and customers seek to establish checks within their business processes and to establish review systems within their organizations, but it is prone to error and oversight especially in light of the complexity of global markets.

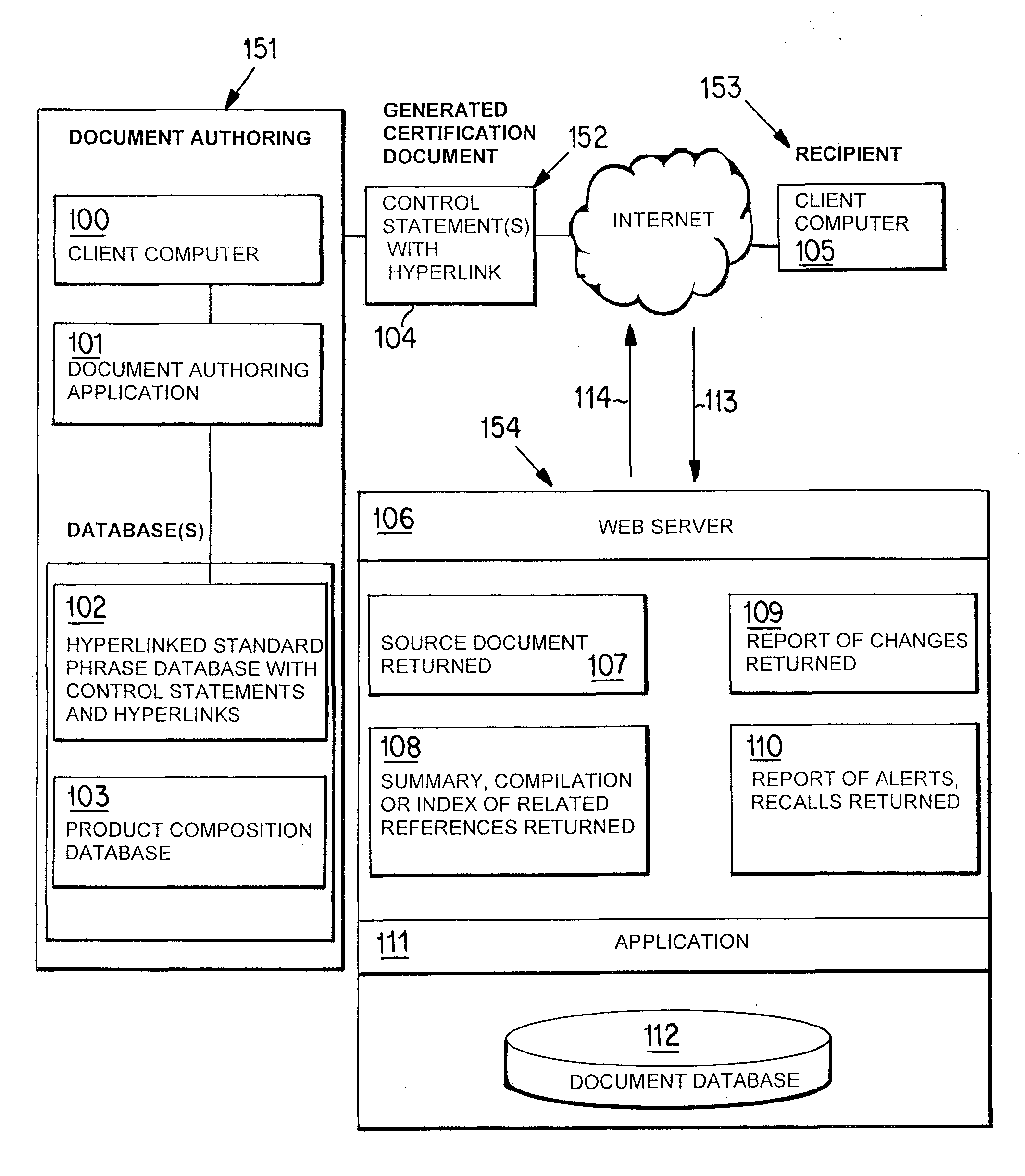

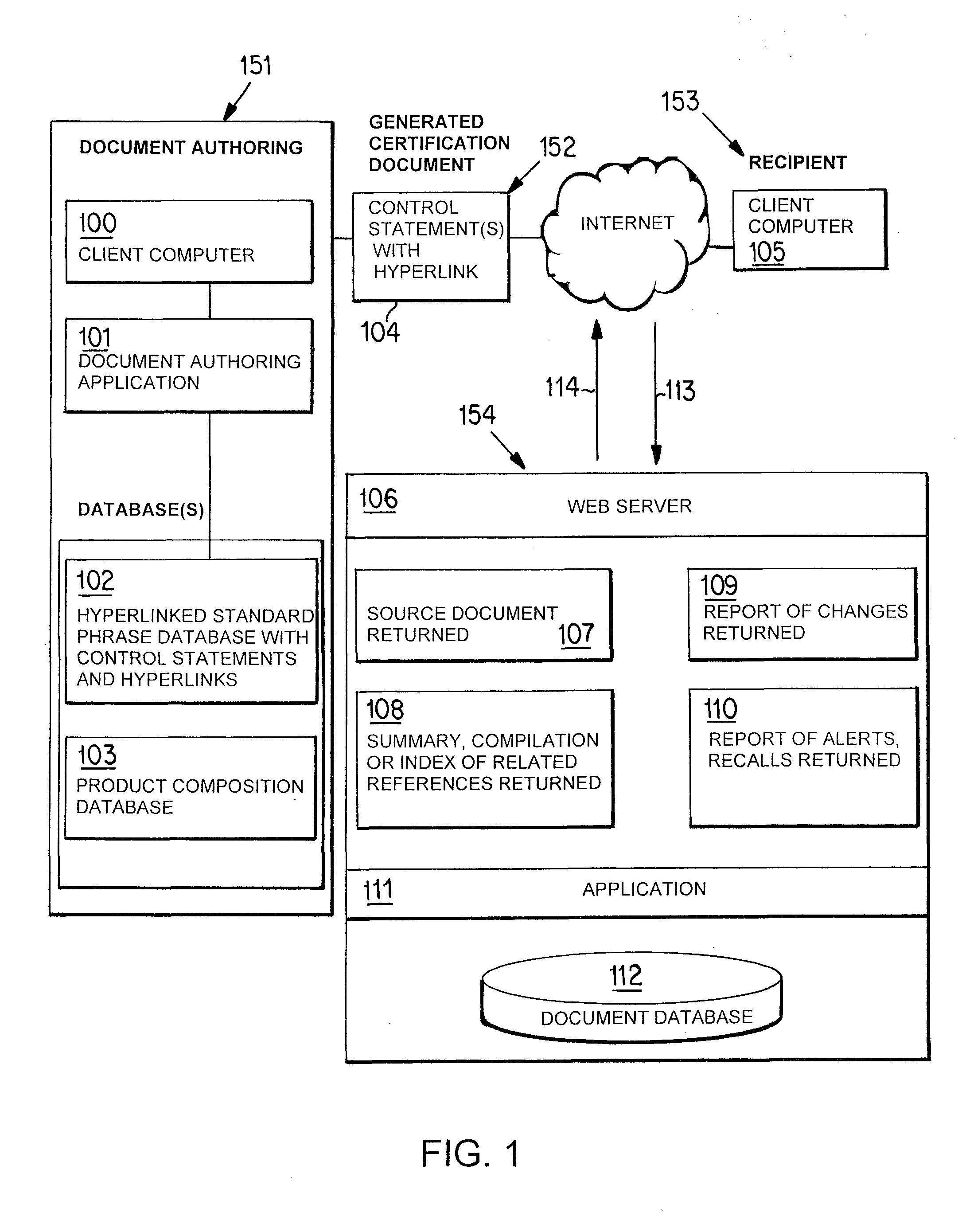

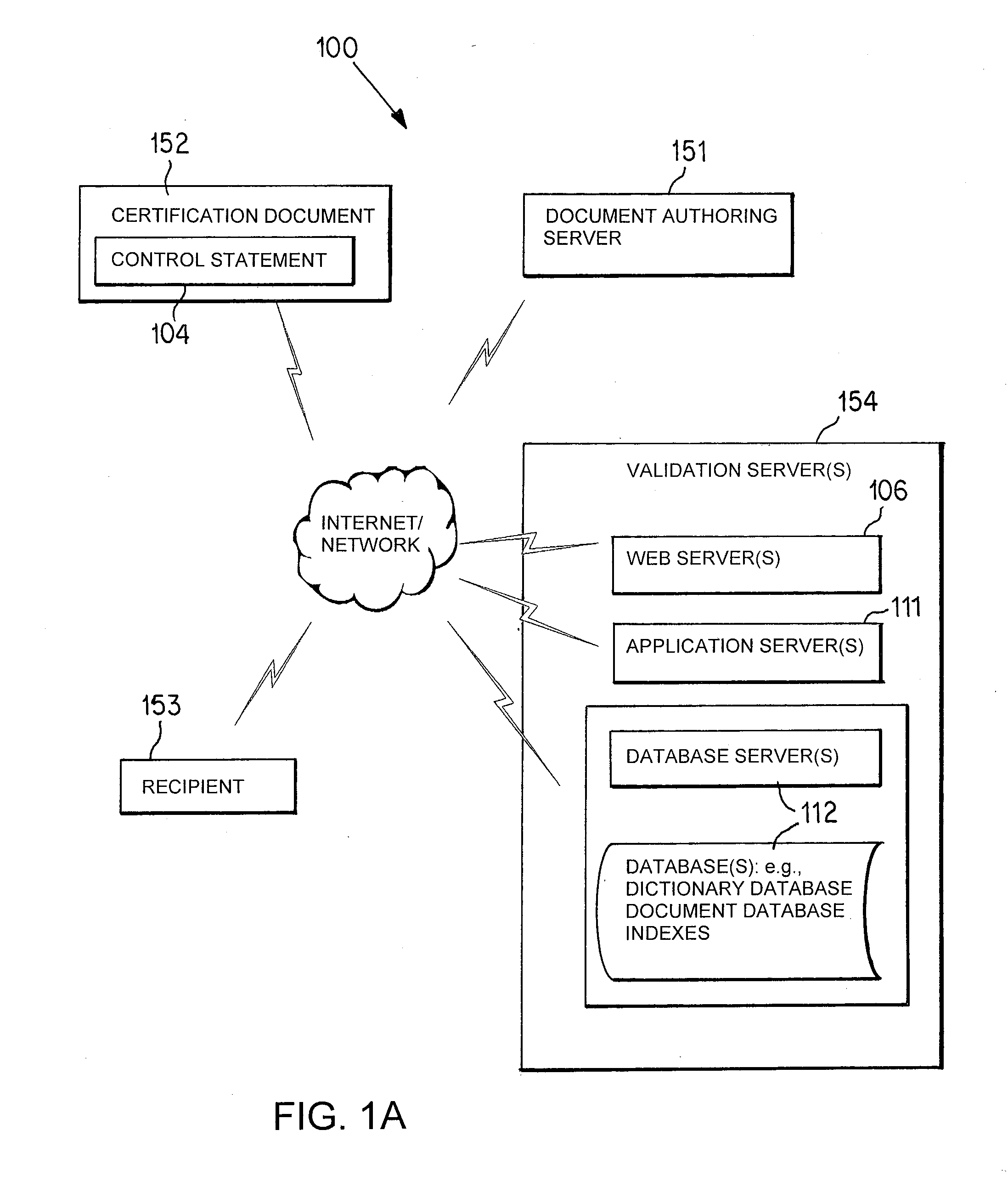

There are a number of current limitations in such systems:ERP and document authoring systems as SAP EH&S, do not today include a dynamic component, such as a

hyperlink, in

phrase libraries of control statements used in the creation of certification documents, one that permits the recipient to validate a control statement within a received document in an automatic manner;ERP and document authoring systems do not provide for validation of control statements through automatic means in generated certification documents for products from within the generated documents;Although it is common for a manufacturer to

hyperlink from a product listing on a web-site page to a related MSDS or technical document associated with the product, for example, it does not exist that the control statements in the certification document

hyperlink to the authoritative

source document for that statement or

data element.

Data processing systems do not exist to pass certification documents containing

dynamic control statements with hyperlinks in business-to-business exchange of such between computer systems in computer readable form so that the control statements with hyperlinks can be extracted and placed in a

database for further use.As a result, such

data processing systems do not today allow the generation of certification documents that permit automated third-party validation and

change management support services in association with control statements made.Such

data processing systems do not use the loading and storage of certification documents with control statements using hyperlinks.It is not possible to obtain direct access to upstream manufacturer control statements or certification documents as described through a central service and no

general practice or

data processing system exists to provide this information.

One of the most difficult tasks of regulatory managers within supplier and customer organizations is keeping up with new or modified regulations or standards.

Equally difficult is the task of determining or obtaining upstream

raw material certifications for products obtained from the immediate supplier.

Further, the downstream recipient does not have a

system by which he can validate the control statements of the upstream provider, if authorized.

The complexity and discontinuity of these two important processes—receiving the certification document and determining changes that relate to such a document's control statements—increase the probability of accidental non-compliance.

Login to View More

Login to View More  Login to View More

Login to View More