Unit type intaglio press

A gravure printing machine and unit-type technology, which is applied in the direction of gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve the problem of low automation of the splicing and cutting device, inability to solve linearity errors, and lower production efficiency of printing machines, etc. Problems, to achieve the effect of not affecting the accuracy of overprinting, uniform ink color, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

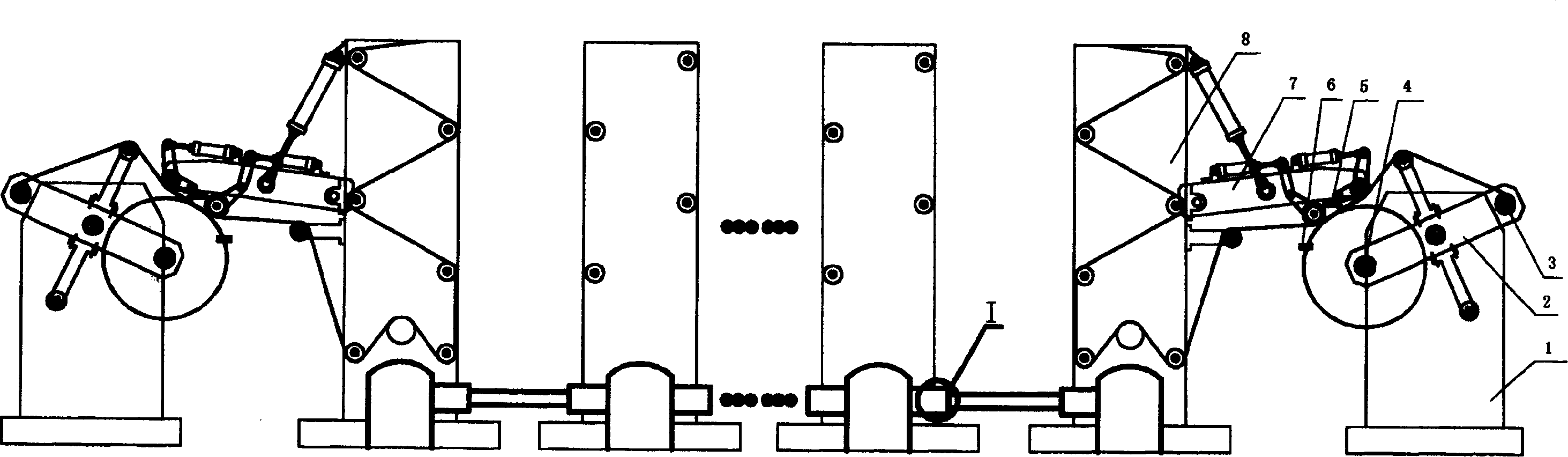

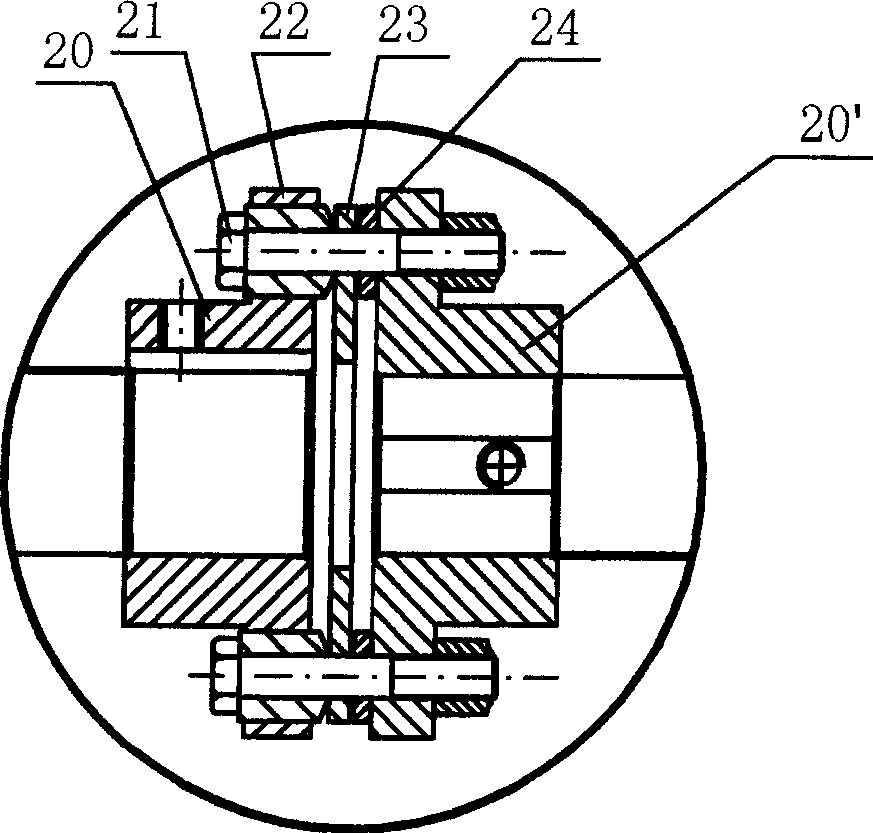

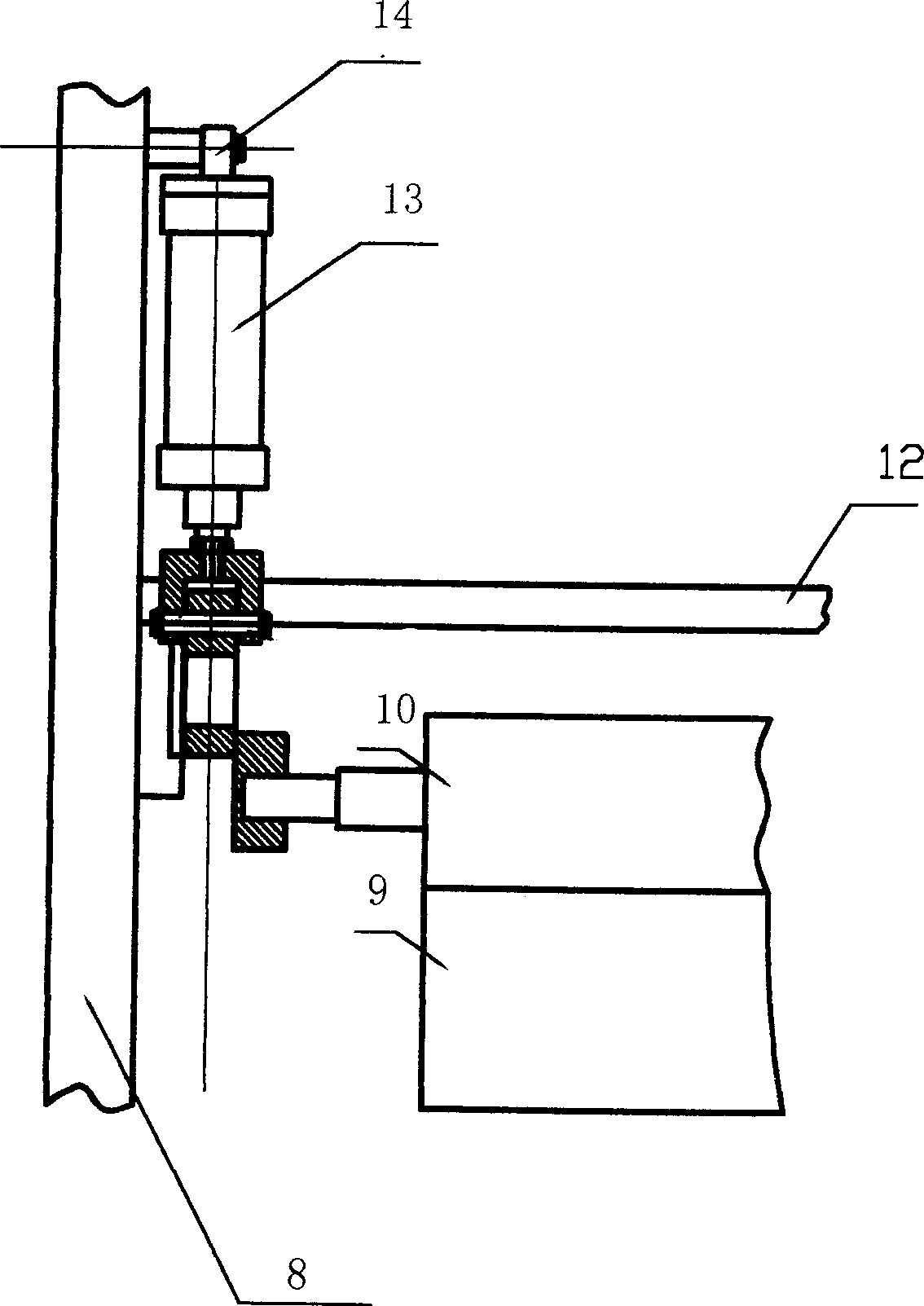

[0010] The accompanying drawings have shown the mechanism of the present invention and its embodiments, and further describe the relevant details of the embodiments in conjunction with the accompanying drawings. The unit-type gravure printing machine has a shaft coupling, an embossing device, and a material connection and cutting device. The connecting shafts of each unit of the printing machine are connected through a coupling, and the material connection and cutting device includes an unwinding frame 1. The unwinding frame 1 is provided with a turning arm 2, the two ends of the turning arm 2 are provided with a first roller 3 and a second roller 4, and the unit wallboard corresponding to the unwinding frame 1 8 is provided with a supporting arm 7, and the coupling is composed of the connecting shaft flanges 20, 20' and the top 24 of two adjacent units, and a set of connecting shaft flanges 20, 20' is arranged between the two 10-20 pieces of steel sheets 23; this group of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com