Sealing system for a water flow control gate

a technology of water flow control and sealing system, which is applied in dams, construction, marine site engineering, etc., can solve the problems of reducing the level of water being held by the gate, reducing or eliminating the usefulness of the gate, and common water leakage between and around the spill-board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

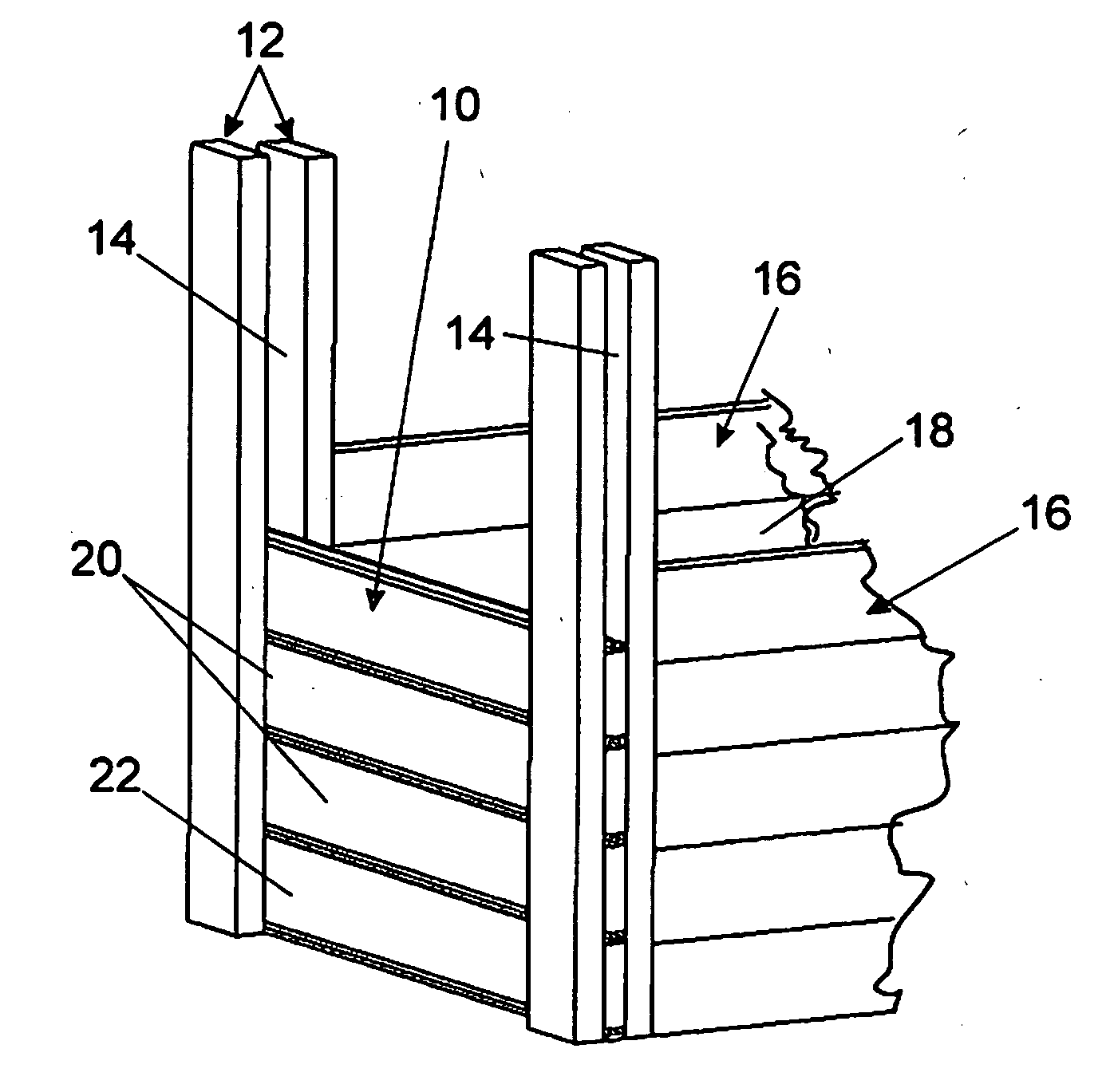

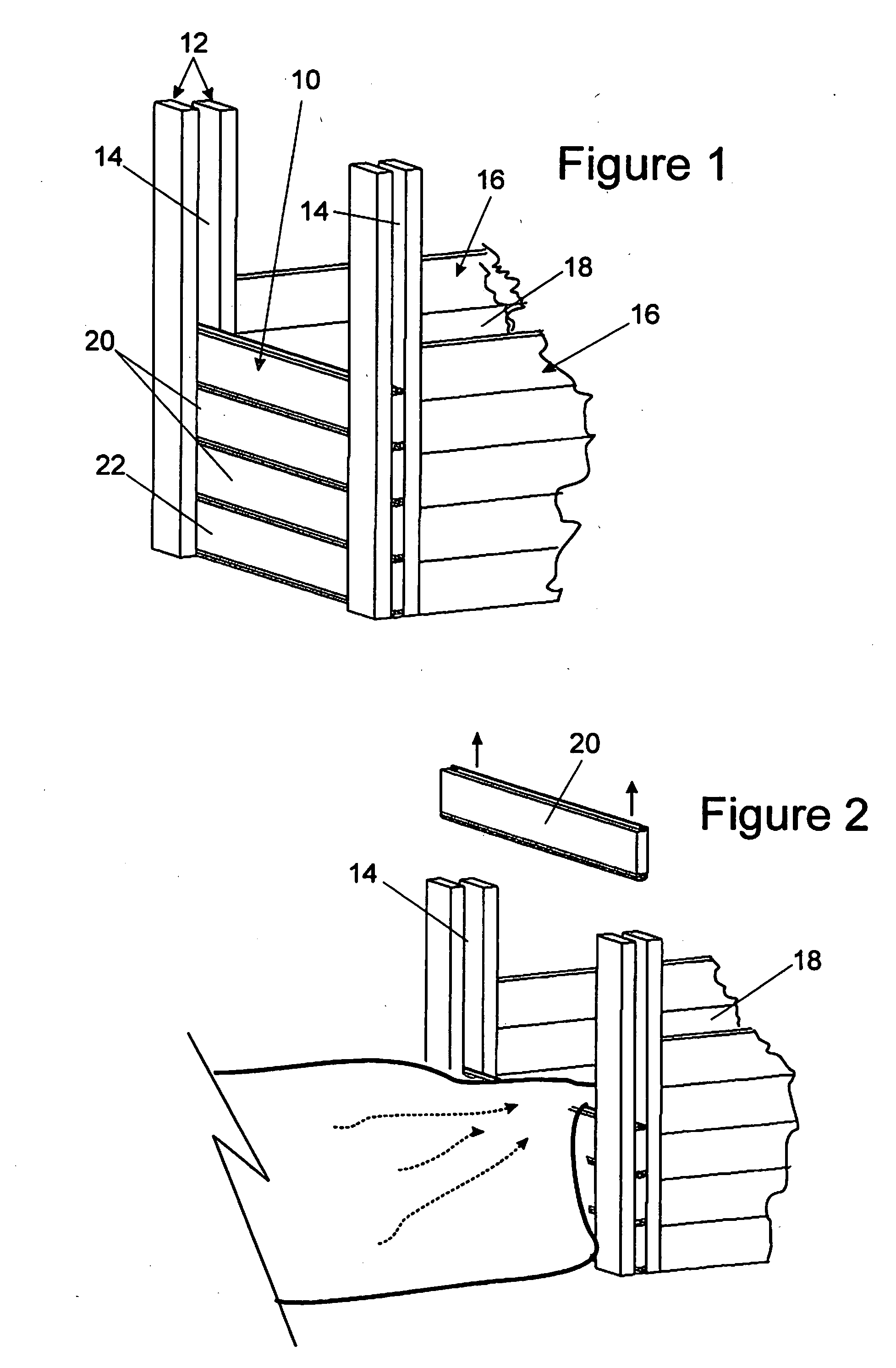

[0035]The present invention provides a sealing system for a water flow control gate. As used herein the term “water flow control gate” refers to any gate which has removable panels, such as stacked horizontal spill-boards that together form a flat face, and that are held in place in a vertical guide way or frame on each end of the spill-boards, and includes sluice gates, flume gates, stoplog gates, slide gates or penstocks or other comparable gates having a comparable function. Generally such water flow control gates also have a cross-bar structure at their top to hold the vertical guide way or frame on the two sides of the channel together.

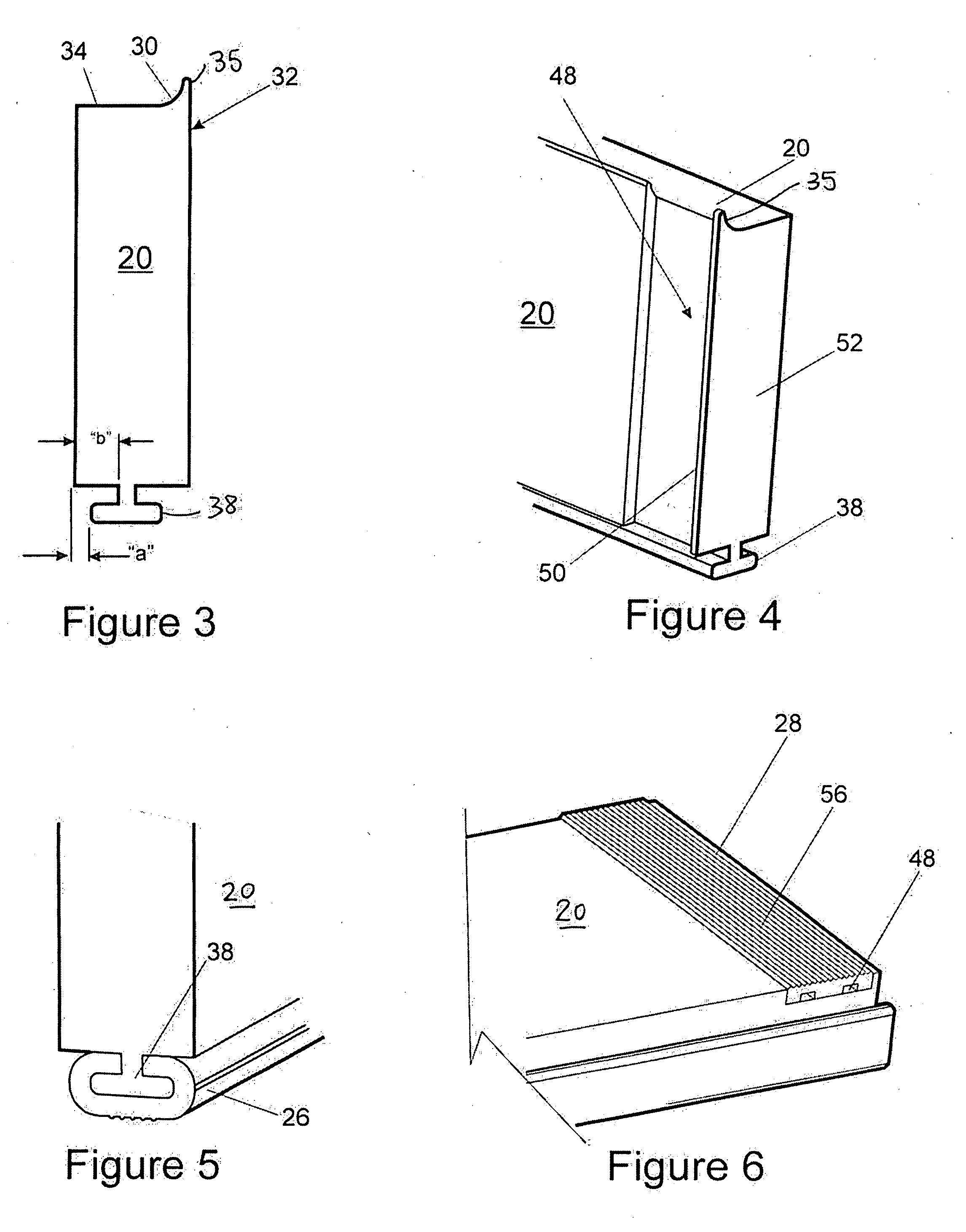

[0036]In particular, the invention herein is a sealing system for a water flow control gate, and a water flow control gate having the sealing system of the invention on each panel forming the gate. Each of a plurality of panels has an upper edge extending the length of the panel with a flat surface rounded upward to a rear side of the panel. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com