Support Leg and A Mobile Offshore Work Platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

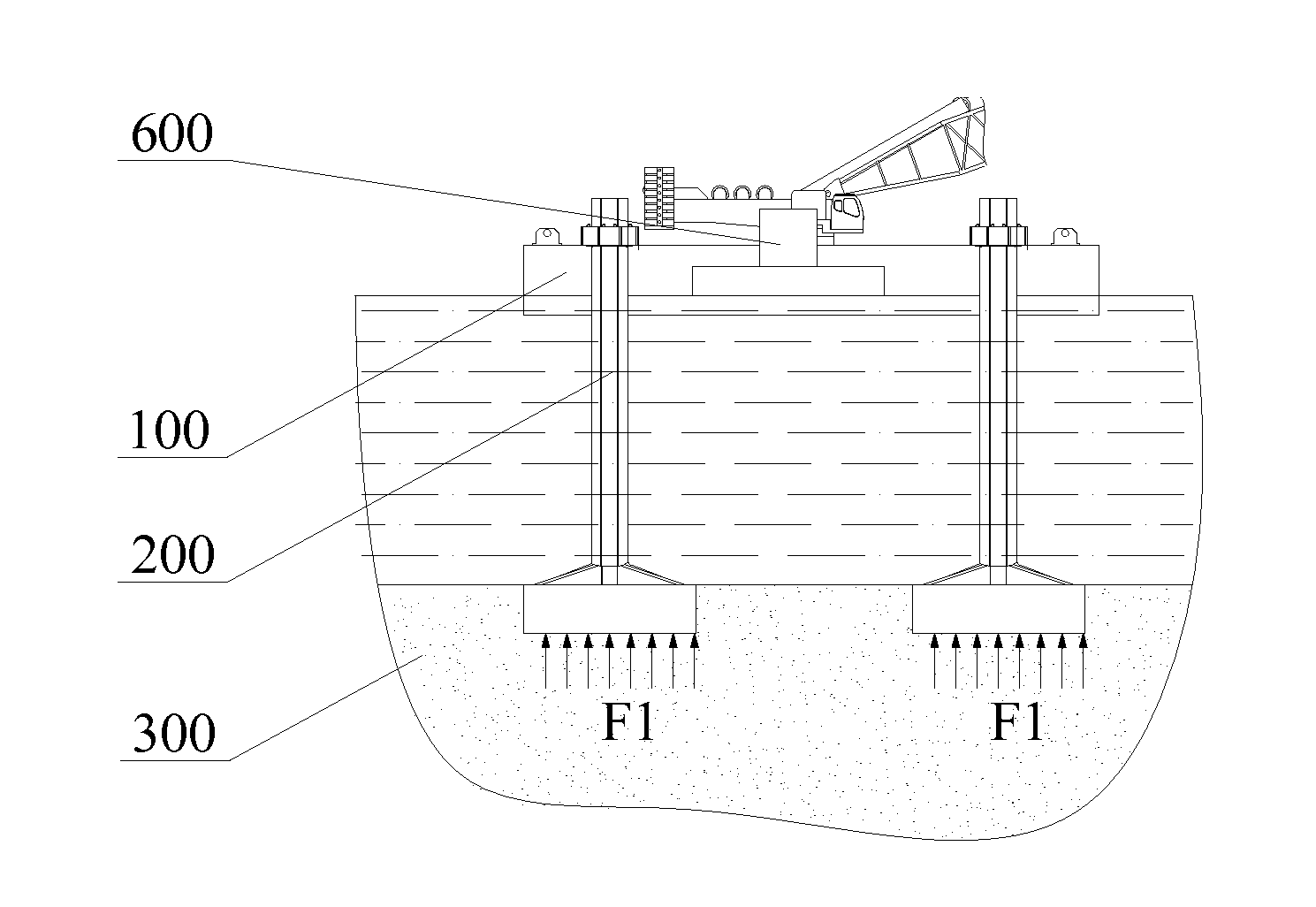

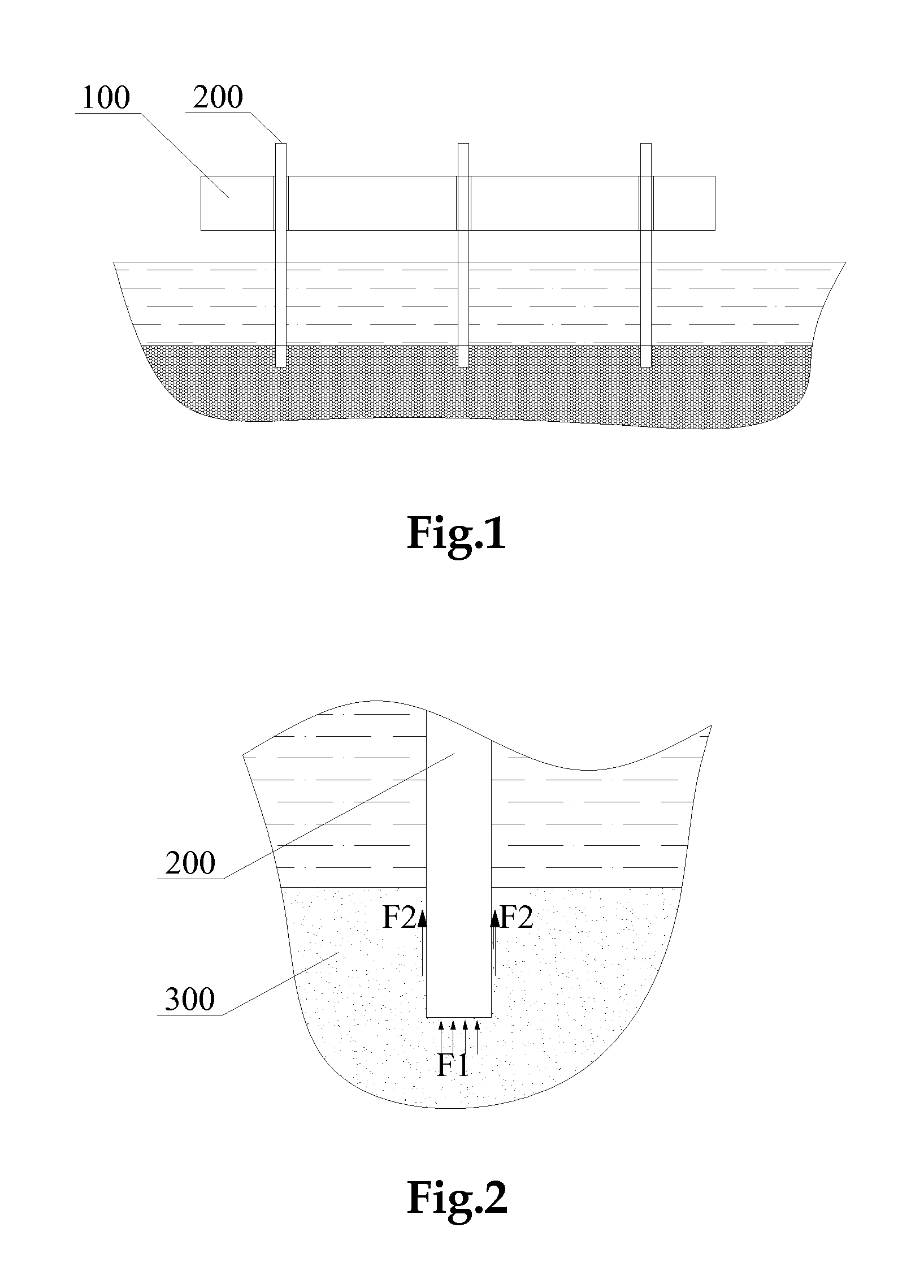

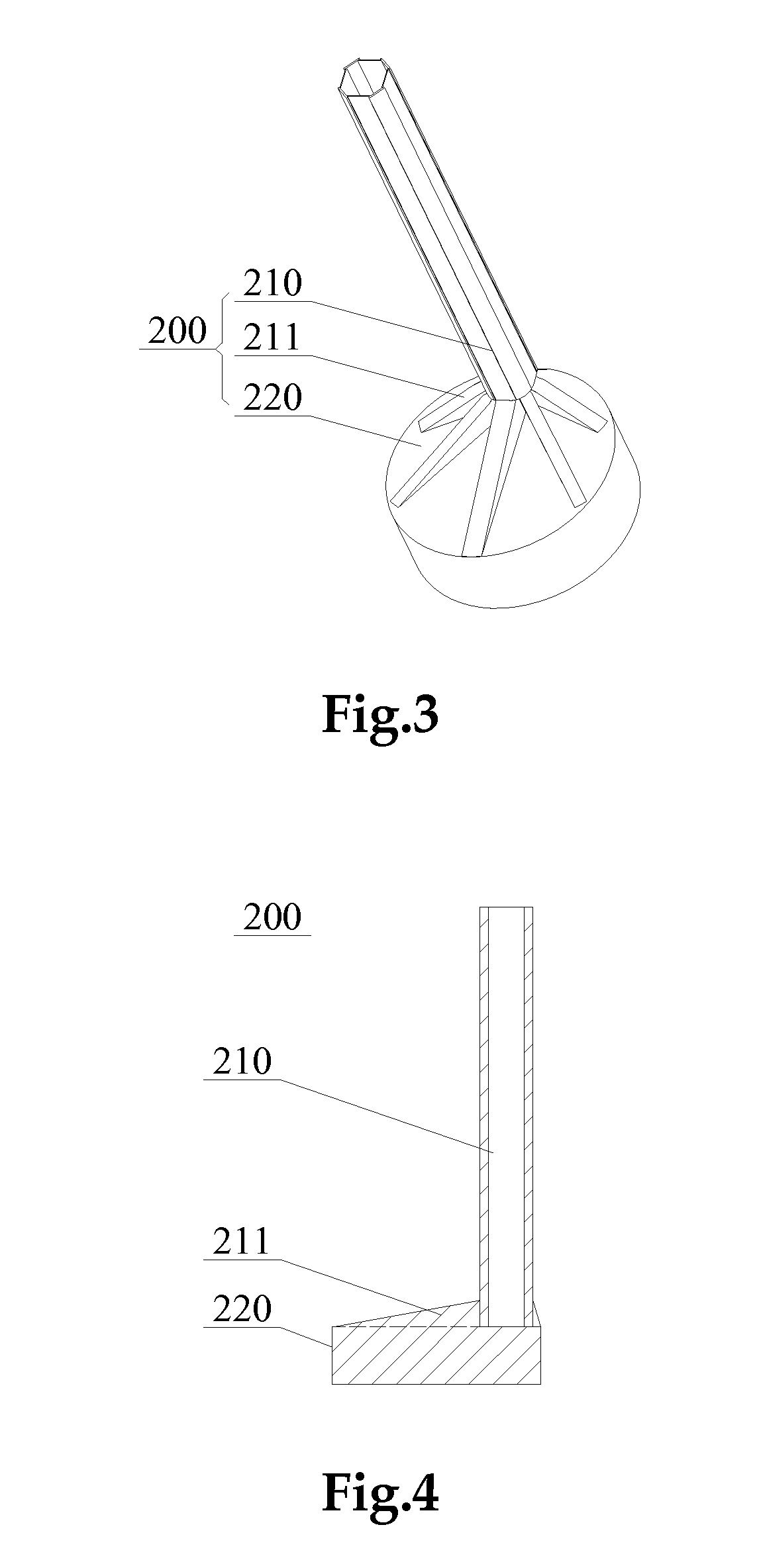

[0046]A support leg 200 according to support leg comprises a support arm 210 and a support platform 220. In this embodiment, the support arm 210 is formed by a hollow steel tube extending in a vertical direction, and the support platform 220 is a plate like body extending in a transversal direction and has a cross section larger than that of the support arm 210. A lower end of the support arm 210 is fixed to an upper surface of the support platform 220. For improving the reliability of fixation between them, between the side surface close to the lower end of the support arm 210 and the upper surface of the support platform 220 there is further provided a plurality of triangular reinforcing ribs 211, which have ends fixed to the side surface of the support arm 210 and bottom surfaces fixed to the support platform 220 and are disposed radially around and close to the lower end of the support arm 210. In addition, in order to facilitate the assembly of the support leg 200 with a platfo...

second embodiment

[0060]Please refer to FIG. 8, which is a schematic view of a structure of a support leg provided by the invention.

[0061]As compared with the support leg provided by the first embodiment of the support leg, one of differences of the support leg provided by the second embodiment is that the support platform 220 comprises a cavity 221 having an opening located on the bottom surface of the support platform 220.

[0062]The operation principle of the support leg 200 is as follows: when the support leg 200 needs to be sunk and supported on the sea floor foundation ground, by using a suitable filling and expelling pump to depressurize the cavity, the air and water in the cavity 221 are evacuated, a negative pressure is created inside the cavity 221, and the support leg is smoothly sunk and deposited on the sea floor foundation ground to provide a support force for the platform body 100; and after the predetermined offshore work has been finished, when the support leg 200 needs to be detached ...

third embodiment

[0065]It can be understood that the purpose of the pressure increment and reduction of the cavity 221 can be realized as long as the external port of the filling and expelling passage 222 is located on the outer surface of the support platforms 220 and the internal port thereof is located at the wall of the cavity 221. Therefore, the external port of the filling and expelling passage 222 may also be located on the other portions of the outer surface of the support platforms 220; as shown in FIG. 9, which is a schematic view of a structure of a support leg according to support leg according to the invention, at this time, the external port of the filling and expelling passage 222 is located between reinforcing ribs 211 on the upper surface of the support platforms 220, and as such, the filling and expelling passage 222 may also be connected with the filling and expelling pump provided on the platform body 100 through a delivery pipe 230; and in a case that predetermined conditions ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com