Cnt-tailored composite land-based structures

a composite land-based structure and carbon nanotube technology, applied in the direction of non-positive displacement fluid engine components, liquid fuel engine components, safety/emergency devices, etc., can solve the problems of damage or even destruction of structures, damage to or damage to structures, and damage to structures that can be repaired quickly to serious or even complete failure without prompt detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

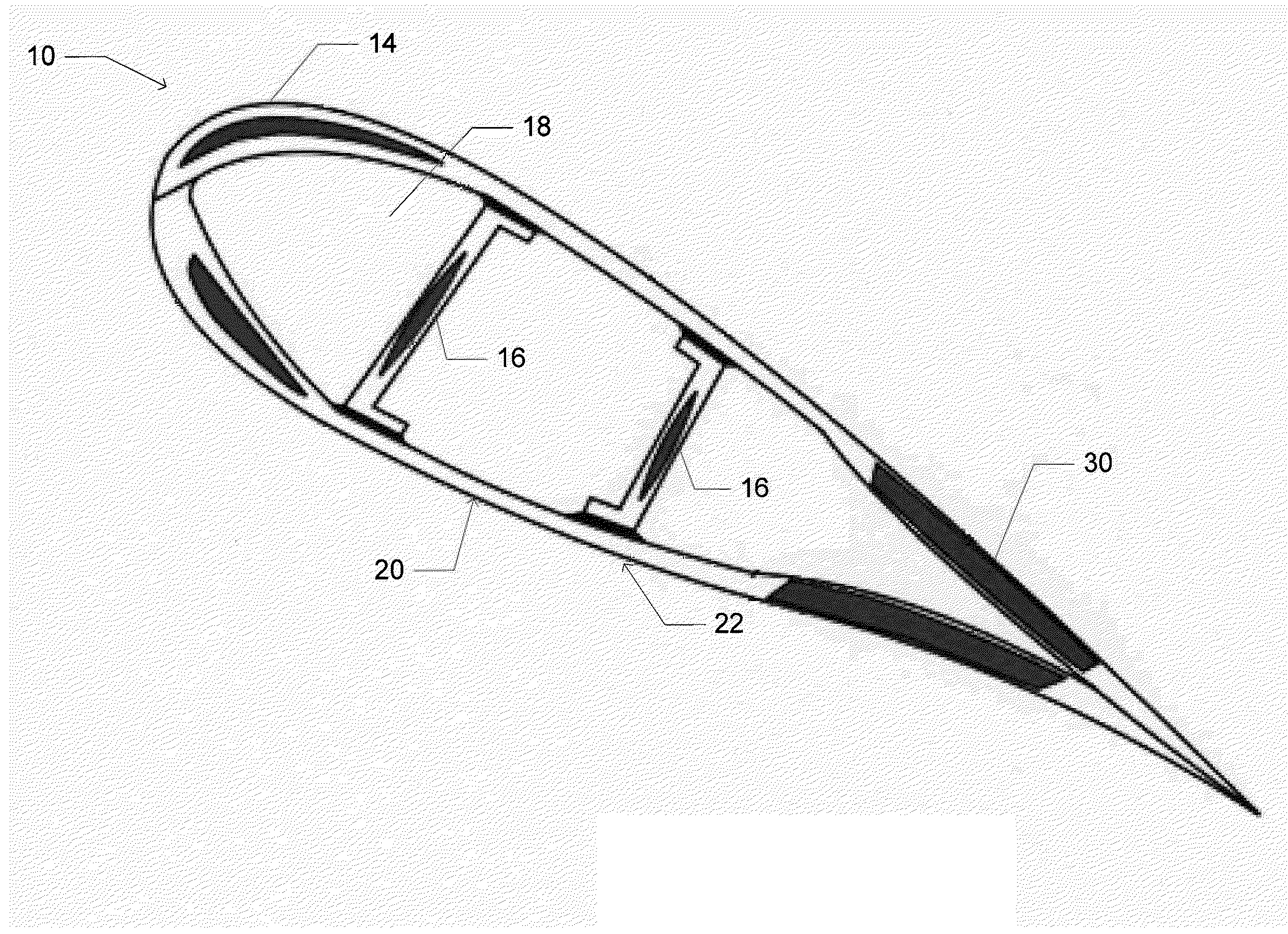

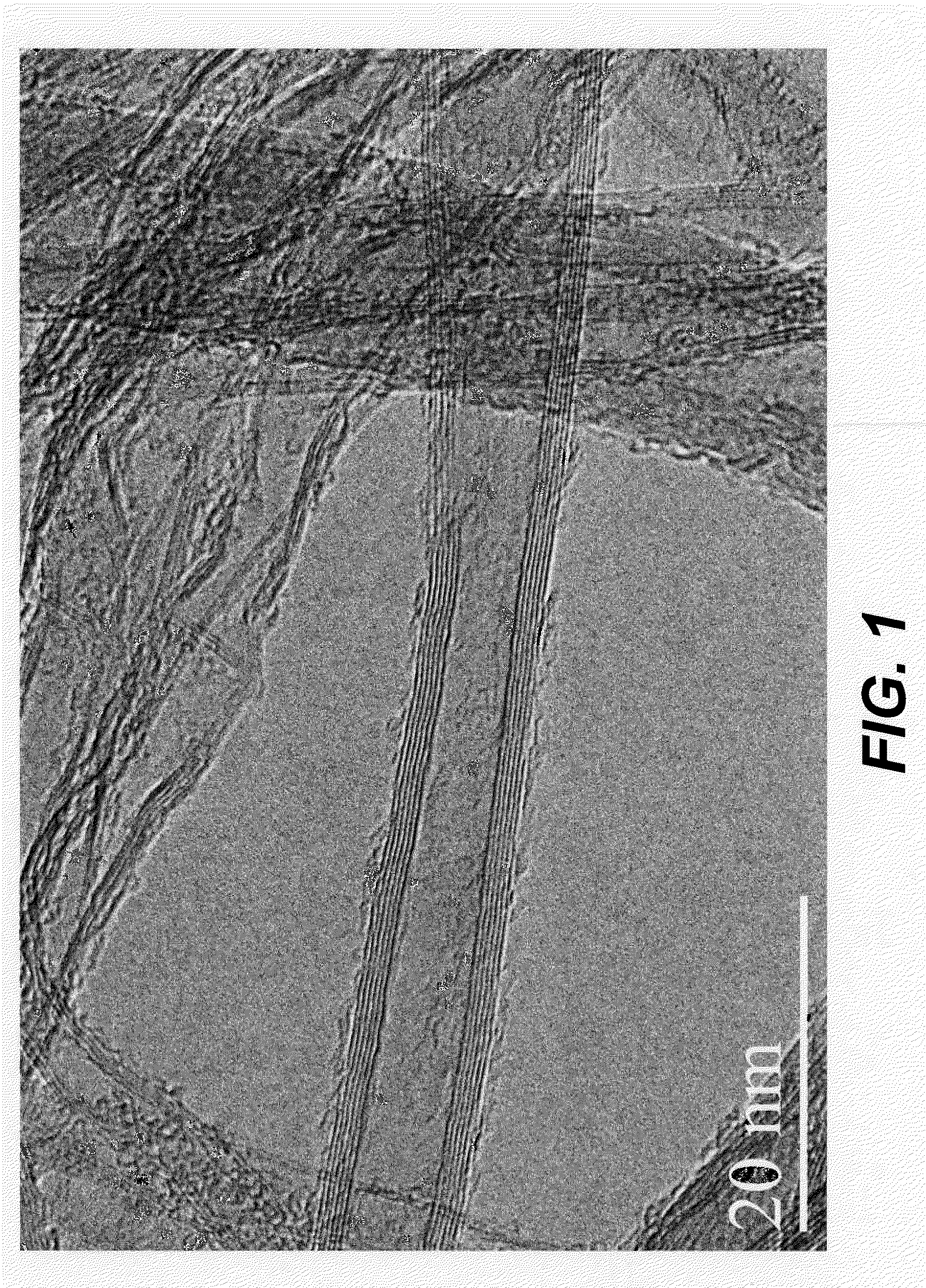

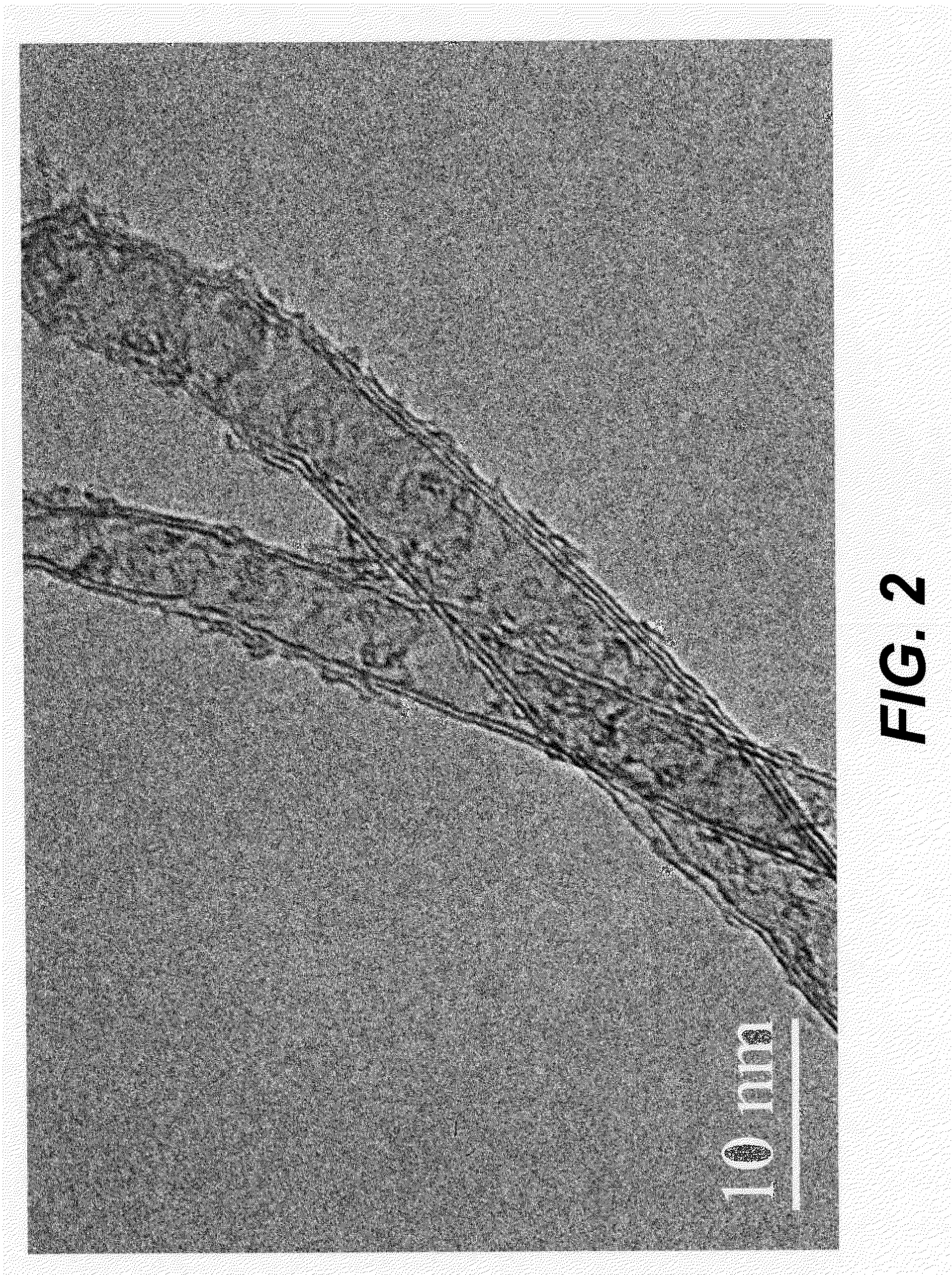

[0018]Tailored multiscale composites have been developed utilizing CNT-infused fibers. CNTs can be grown directly onto the surface of glass and carbon fibers in a continuous, in line process utilizing a modified CVD process, such as the one described in Applicant's co-pending applications, U.S. Publication Nos. 2010 / 0279569 and 2010 / 0178825, both of which are incorporated herein by reference in their entirety. Composite structures made with CNT-infused fiber materials have shown increased mechanical properties, specifically in shear—interlaminar and in-plane. Additionally these composite structures have improved electrical and thermal conductivity, based on the CNT loading and orientation. These CNT-infused fiber materials can be used in composite structures in various orientations and locations to provide custom tailored properties, including properties not available to current fiber materials.

[0019]The CNT-infused fiber composite can employ any type of fiber substrate, including, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com