Applicator, in particular mascara applicator, pigment compound stick therefor, and cosmetic product

a technology of pigment compound stick and applicator, which is applied in the field of mascara applicators, can solve the problems of easy clogging, unsatisfactory application, and uneven wetting of the outside of the applicator along its longitudinal span, and achieves the effect of large flexibility for users during us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

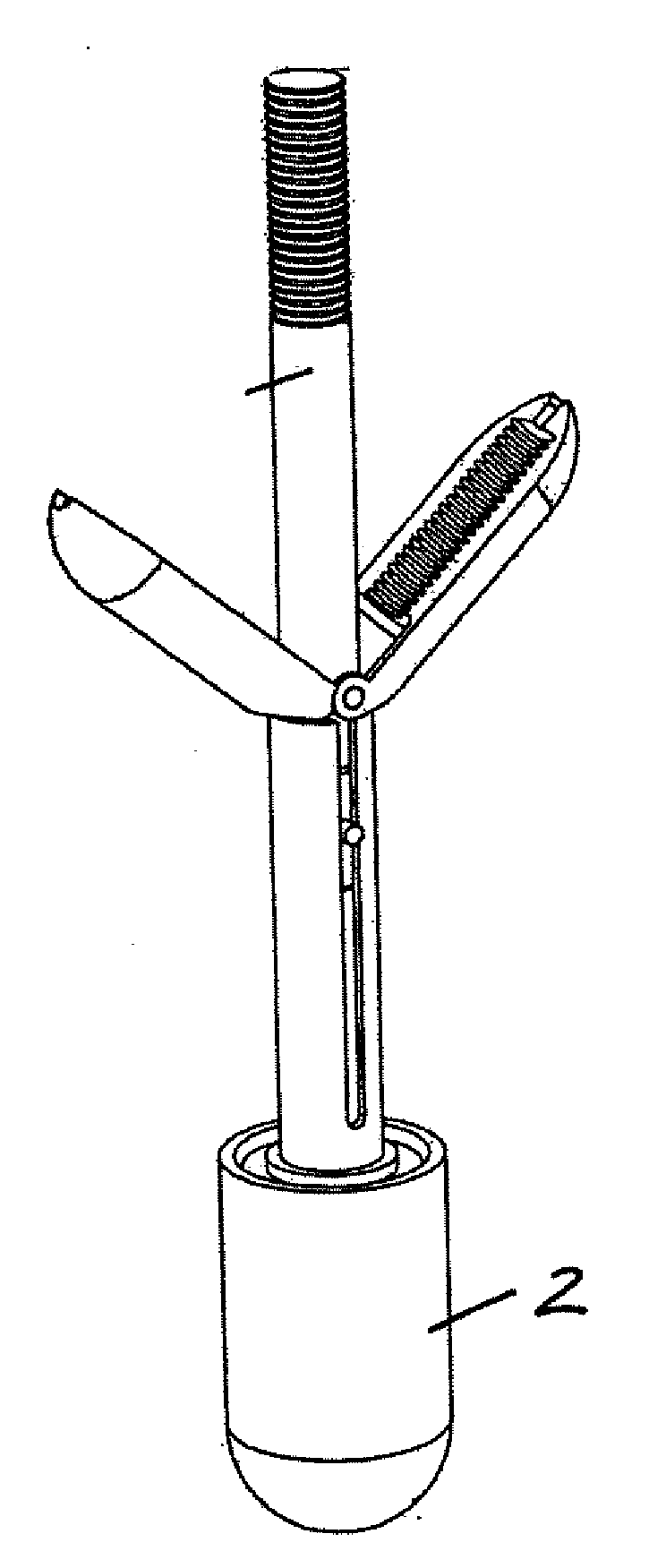

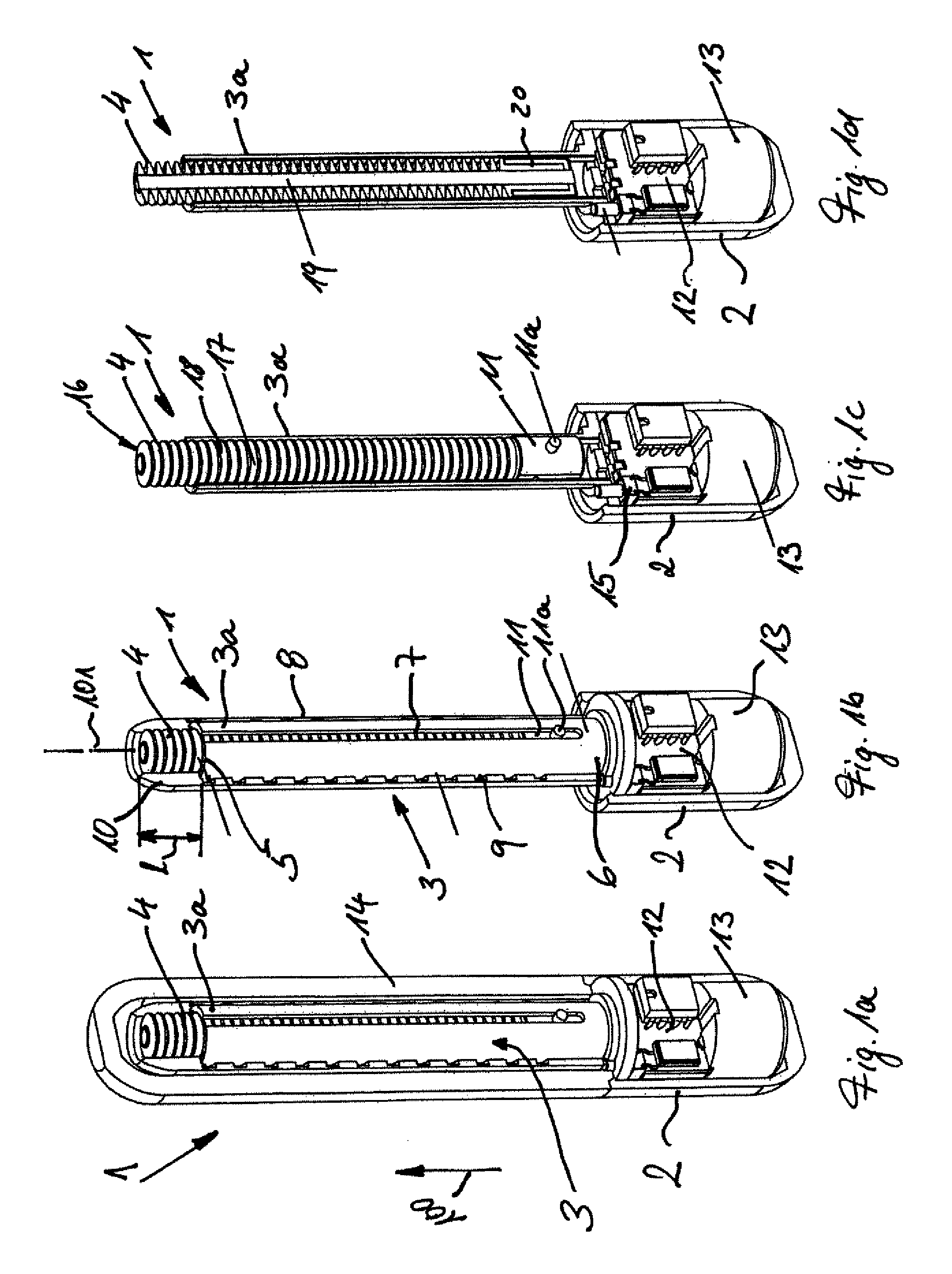

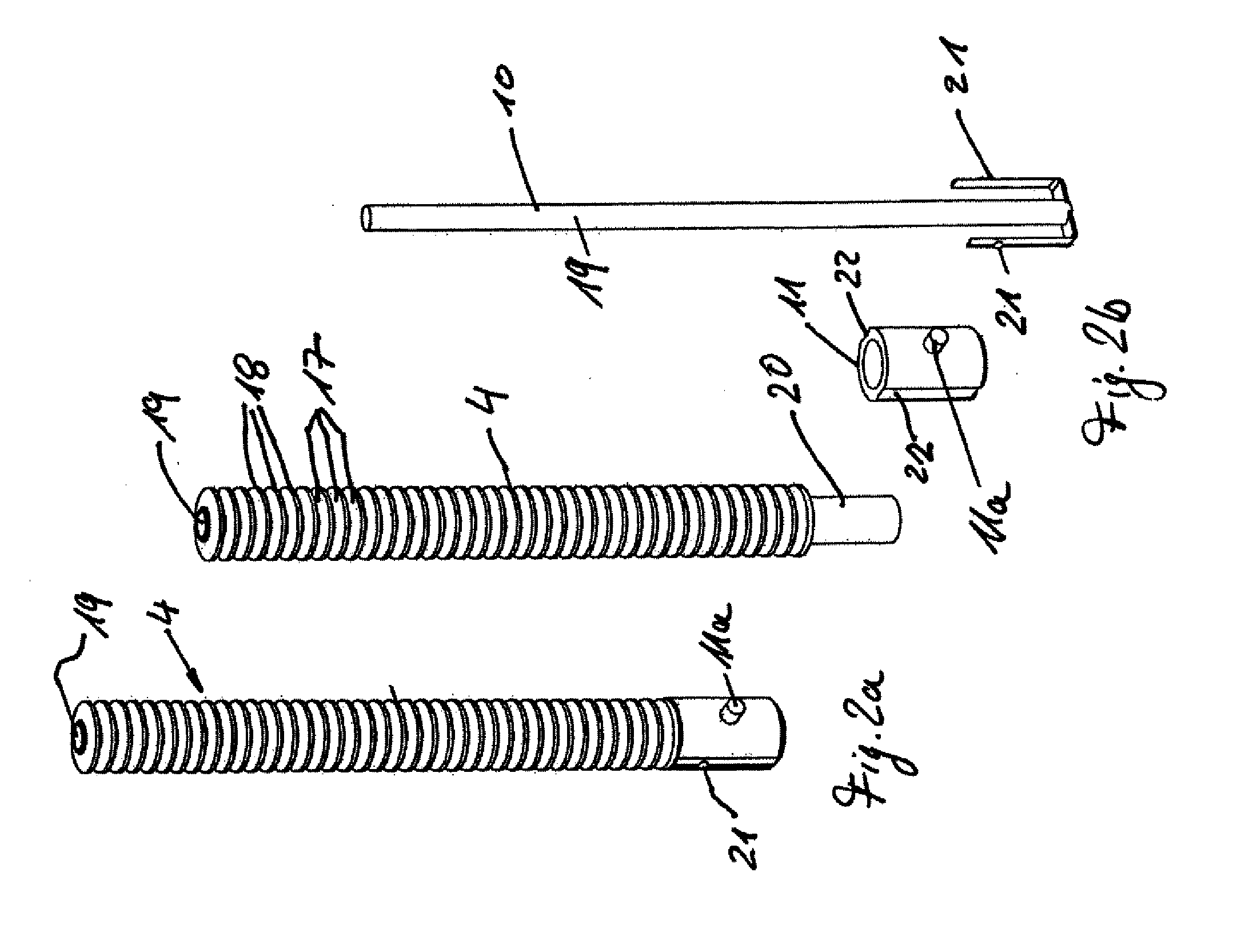

[0052]An applicator 1 according to the invention (FIGS. 1a through 1d) has a grip 2 and a housing section 3 extending away from the grip 2 in a longitudinal direction 100 for accommodating pigment compound, e.g. mascara pigment compound. In the present embodiment, the housing section 3 is formed jointly by the feed screw sleeve 8 and the heating element 10 (which has an external casing here). The pigment compound is embodied in the form of a pigment compound stick 4 and has a pigment compound that is solid at customary ambient temperatures. Customary ambient temperatures are understood, for example, to mean a range between 20° C. and 35° C. In this exemplary embodiment, the term “solid” is understood to mean that the pigment compound stick is inherently dimensionally stable during customary use conditions of the mascara applicator so that an inherently dimensionally stable oblong structure in the form of a stick is provided, which preferably is self-supporting or is lent sufficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com