Fabric Strap with Multi-Layer Structure For Air-Cushion Effect And Uses Thereof In Underwear

a fabric strap and multi-layer technology, applied in the field of fabric straps, can solve the problems of large tension on the underwear strap, complicated working procedures, and discomfort for the wearer, and achieve the effect of reducing pressure, reducing discomfort, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The following is the detailed description of an embodiment of the present utility model with reference to the attached figures.

First Detailed Description of the Preferred Embodiments

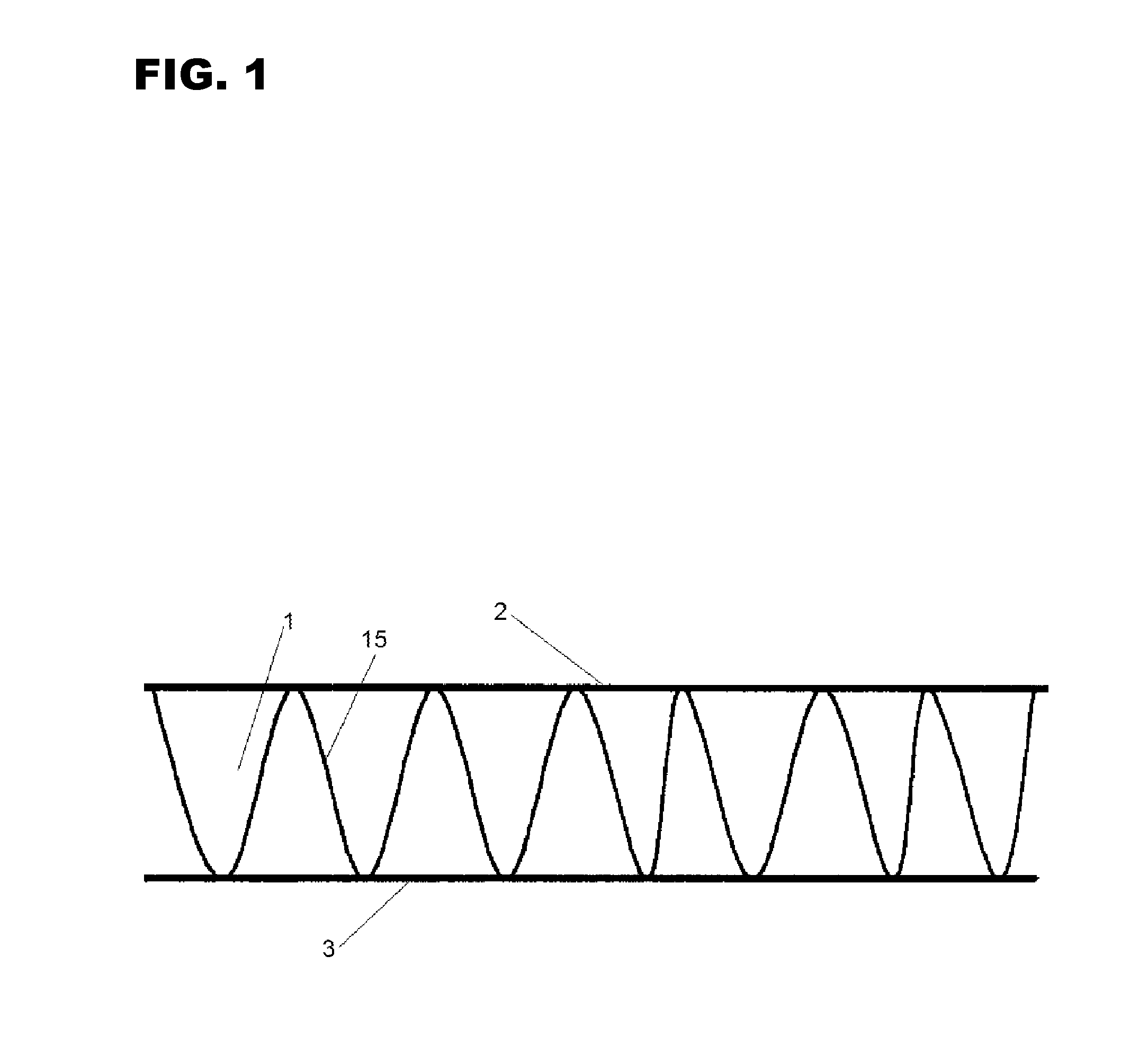

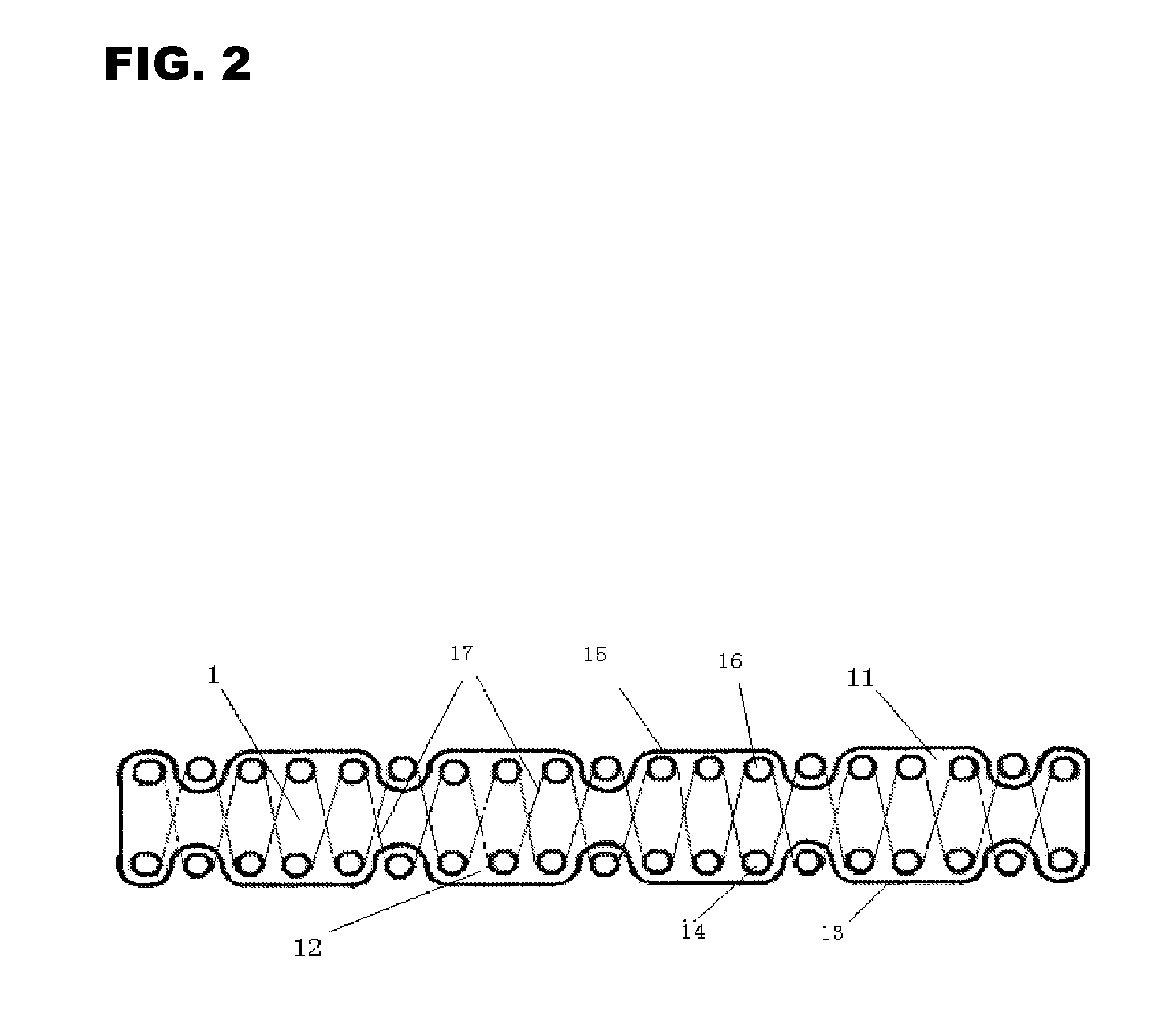

[0040]Shown in FIG. 1 and FIG. 2 is a fabric strap with air cushion protection containing the fabric strap itself. Said fabric strap itself has a double layer structure by integral weaving. Said double layer structure contains upper-layer fabric (11) and lower-layer fabric (12). Said upper-layer fabric (11) and lower-layer fabric (12) form the air cushion (1) with a structure of erect fine hairs by interweaving with the napped warps of upper- and lower-layers (17). Since the air cushion (1) composed of erect fine hairs are thicker and softer and also has the effect of relieving pressure, so that when said fabric strap with air cushion of the present utility model is used as an underwear strap, the pressure on the skin caused by the fabric strap can be effectively relieved, thus increasing comfort o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structure | aaaaa | aaaaa |

| elastic | aaaaa | aaaaa |

| non-elastic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com