Piezoelectric fan and cooling device

a piezoelectric fan and cooling device technology, applied in the direction of positive displacement liquid engine, piston pump, semiconductor/solid-state device details, etc., can solve the problems of affecting the air-moving performance of the piezoelectric fan, affecting the accuracy of positioning, and limiting the precision of positioning, so as to achieve the effect of improving the overall size of the cooling device, improving the air-moving performance of the vibrating plate and significantly increasing the cooling performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

[0053]Hereinafter, a piezoelectric fan according to a first preferred embodiment of the present invention will be described.

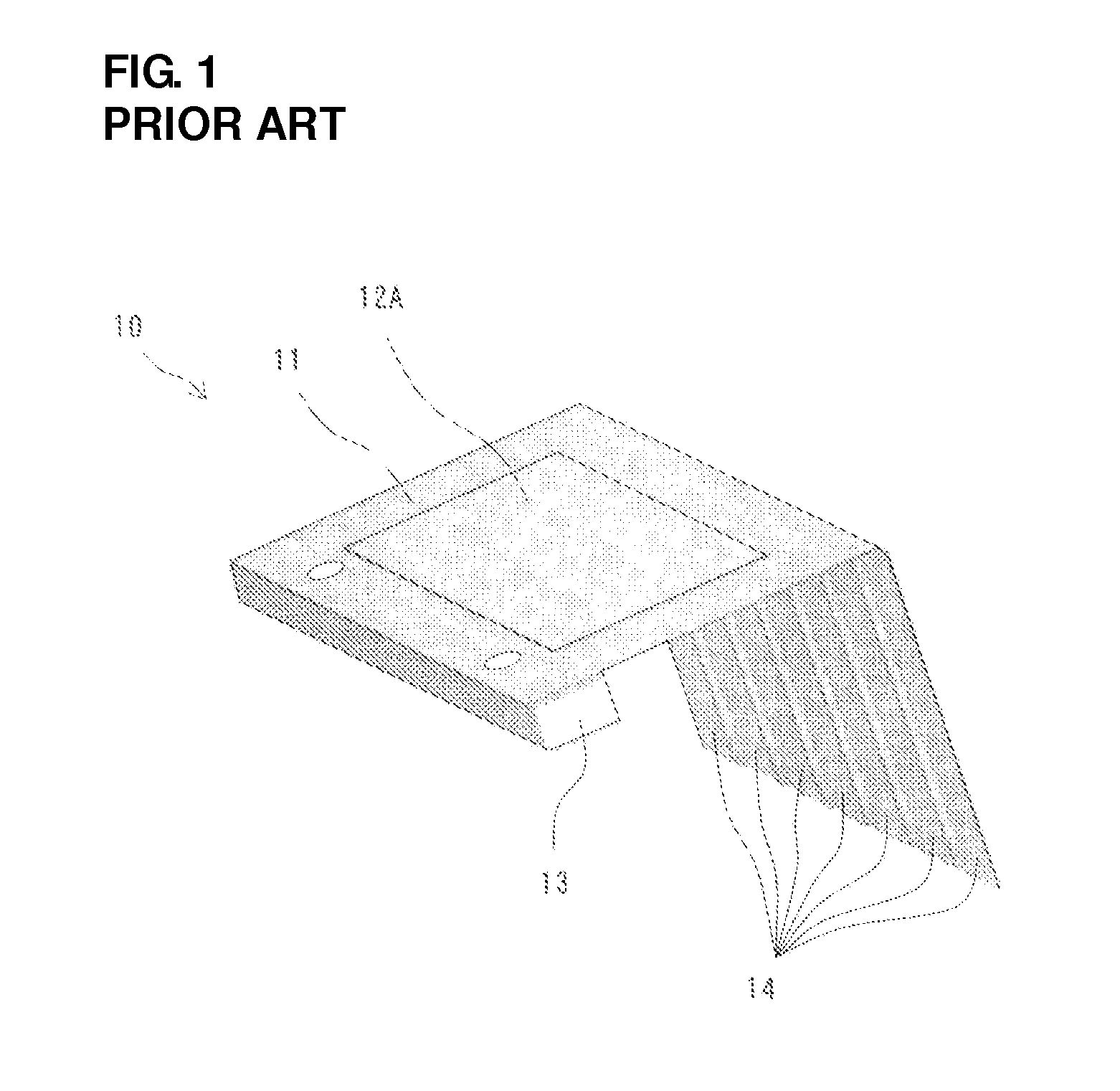

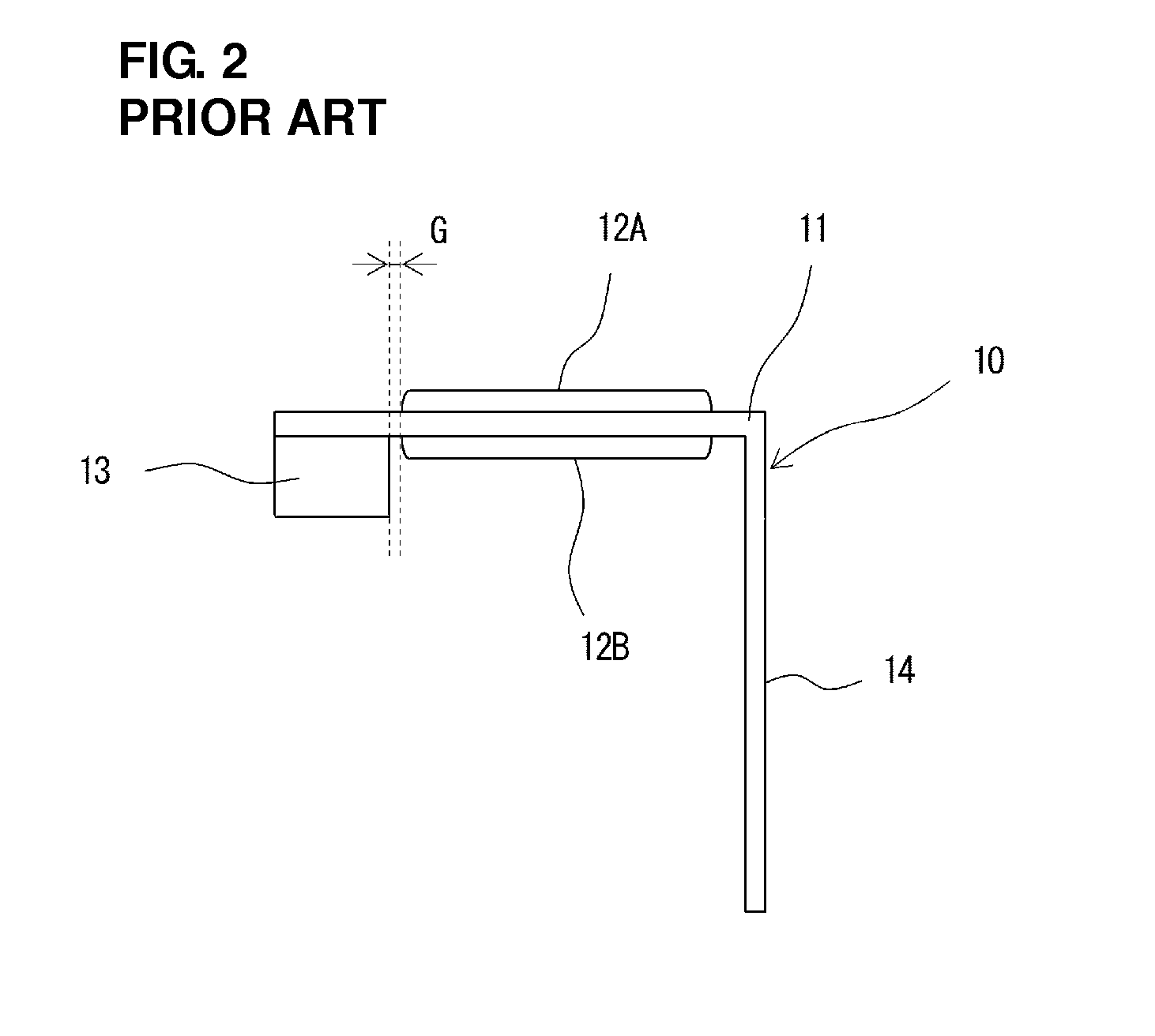

[0054]FIG. 4 is a perspective view of a piezoelectric fan 101 according to the first preferred embodiment, and FIG. 5 is a side view of the piezoelectric fan 101. FIGS. 6A and 6B are perspective views of a cooling device 1 including the piezoelectric fan 101. In FIG. 5, a vibrating plate is seen in side view in a direction in which the boundary between piezoelectric elements and a fixing member is visible. A gap G is illustrated in a slightly enlarged scale for convenience of illustration.

[0055]The piezoelectric fan 101 include a vibrating plate 111, piezoelectric elements 112A and 112B, a fixing plate 113, and reinforcing plates 151 and 152. A heatsink 20 preferably includes heat-dissipating fins 22 that extend upward from the base portion 21 so as to be parallel to each other. In FIGS. 6A and 6B, a heat-generating member 50 (heat-generating component), such a...

second preferred embodiment

[0070]FIG. 8A is a top view of a fixing plate 213 of a piezoelectric fan 201 according to a second preferred embodiment of the present invention, FIG. 8B is a front view of the fixing plate 213, and FIG. 8C is a side view of the fixing plate 213. FIG. 9 is a top view of the piezoelectric fan 201 according to the second preferred embodiment. FIG. 10 is a side view of the piezoelectric fan 201. In FIG. 10, a vibrating plate is shown in a side view in a direction in which the boundary between piezoelectric elements and a fixing member is visible.

[0071]The piezoelectric fan 101 according to the first preferred embodiment includes the reinforcing plates 151 and 152 arranged to increase the rigidity of the portion of the vibrating plate 111 corresponding to the gap G. The piezoelectric fan 201 according to the second preferred embodiment includes the fixing plate 213 preferably made of glass epoxy, for example, which is illustrated in FIGS. 8A to 8C. The fixing plate 213 preferably includ...

third preferred embodiment

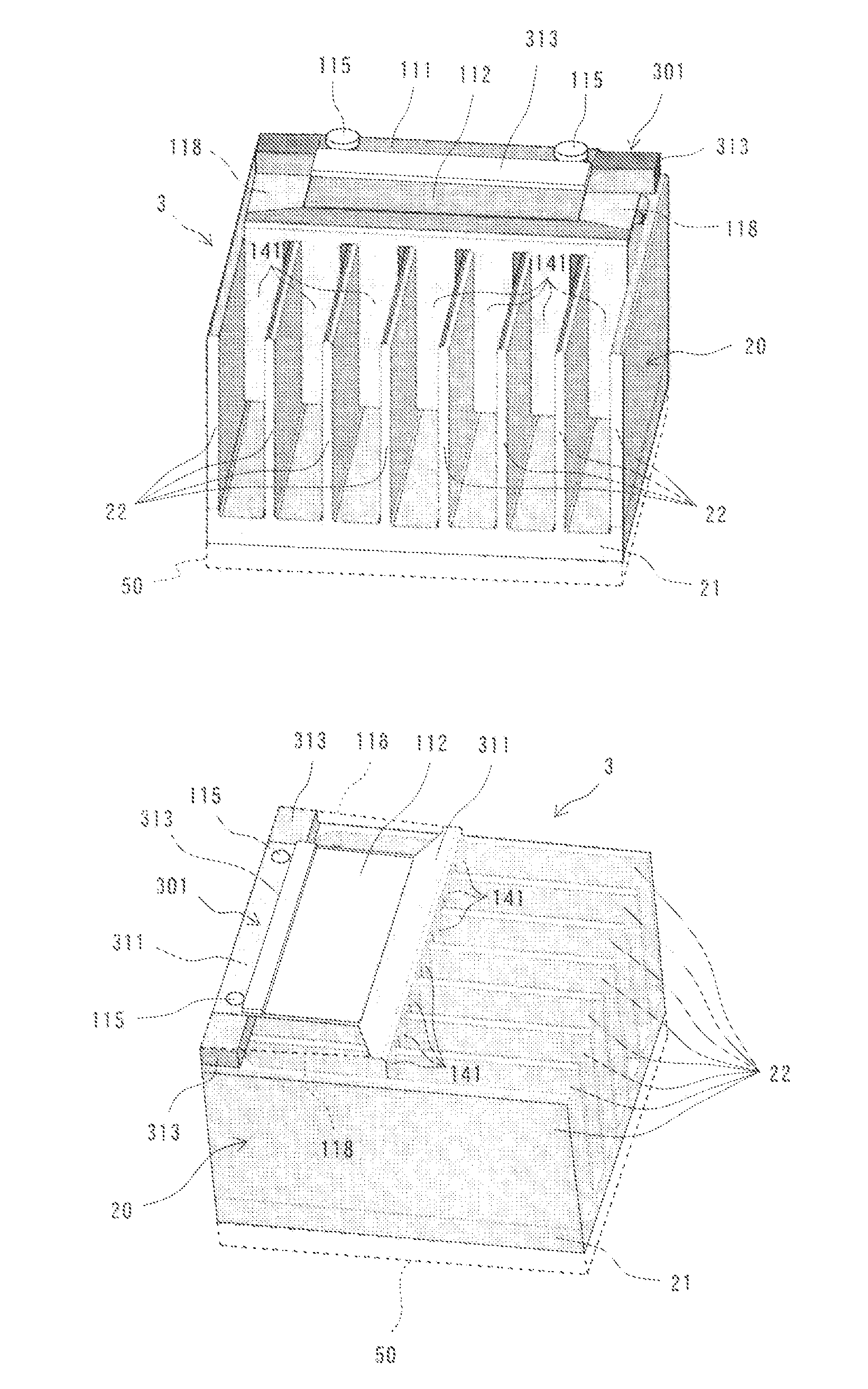

[0078]FIG. 11 is a perspective view of a piezoelectric fan 30, which is a modification of the piezoelectric fan 10 described in Kaneko. FIG. 12 is a perspective view of a piezoelectric fan 301 according to a third preferred embodiment of the present invention. FIG. 13 is a side view of the piezoelectric fan 301 according to the third preferred embodiment. FIGS. 14A and 14B are perspective views of a cooling device 3 including the piezoelectric fan 301 according to the third preferred embodiment. In FIG. 13, a vibrating plate is shown in side view in a direction in which the boundary between piezoelectric elements and a fixing member is visible.

[0079]First, in order to compare the air-moving performance of the piezoelectric fan 301 of the third preferred embodiment with the air-moving performance of the piezoelectric fan 30, which is a modification of the piezoelectric fan 10, the structure of the piezoelectric fan 30 will be described.

[0080]The piezoelectric fan 30 differs from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com