Reduction of Greenhouse Gases

a technology of greenhouse gas and greenhouse gas, applied in the field of greenhouse gas reduction, can solve the problems of very limited methods of minimizing stacks, and achieve the effects of reducing greenhouse gas emissions, reducing waste heat to the receiving stream, and reducing greenhouse emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Brief Description of Drawings

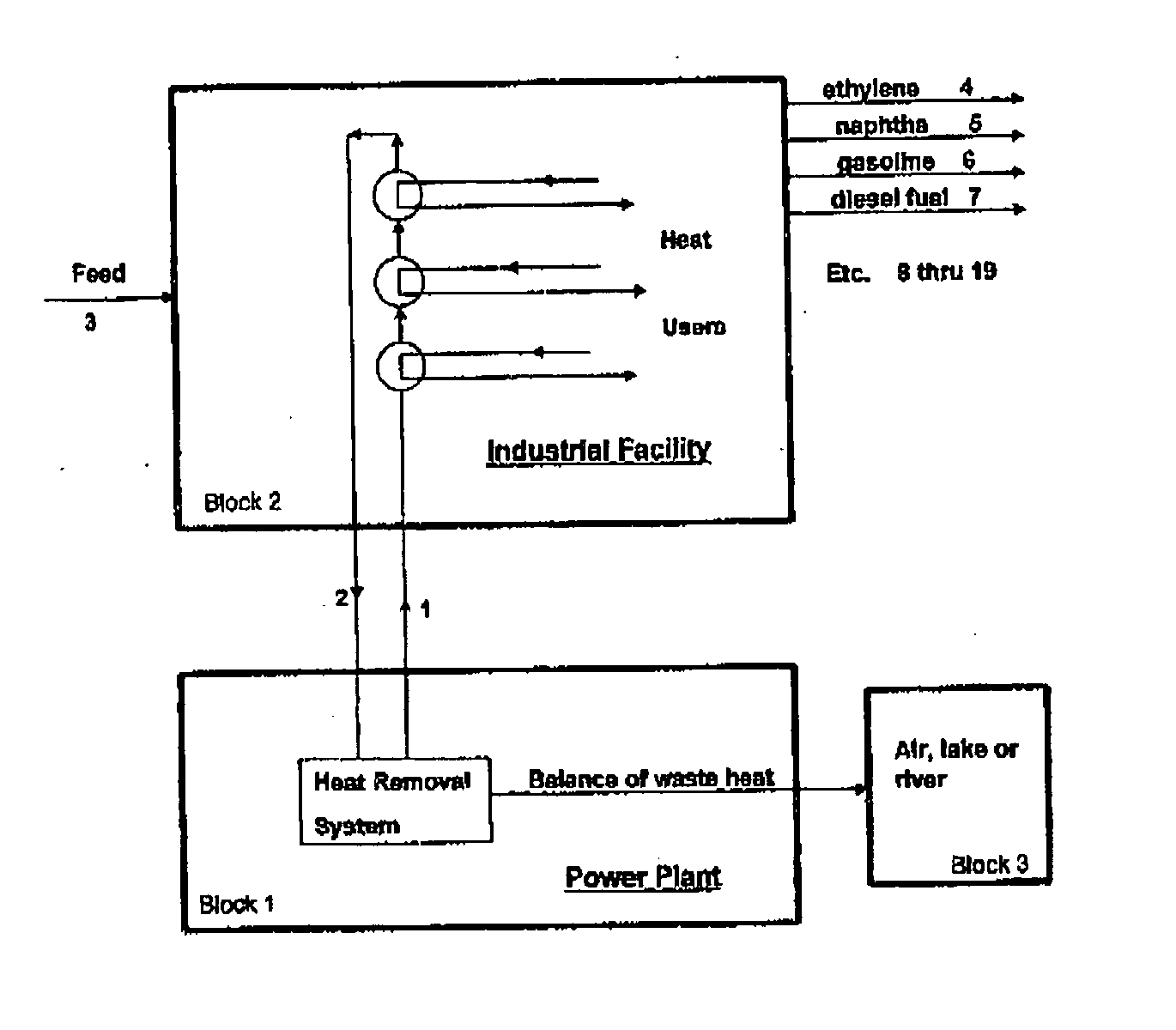

[0015]FIG. 1 is a schematic of the base processing scheme and also Alternate No. 1 processing scheme.

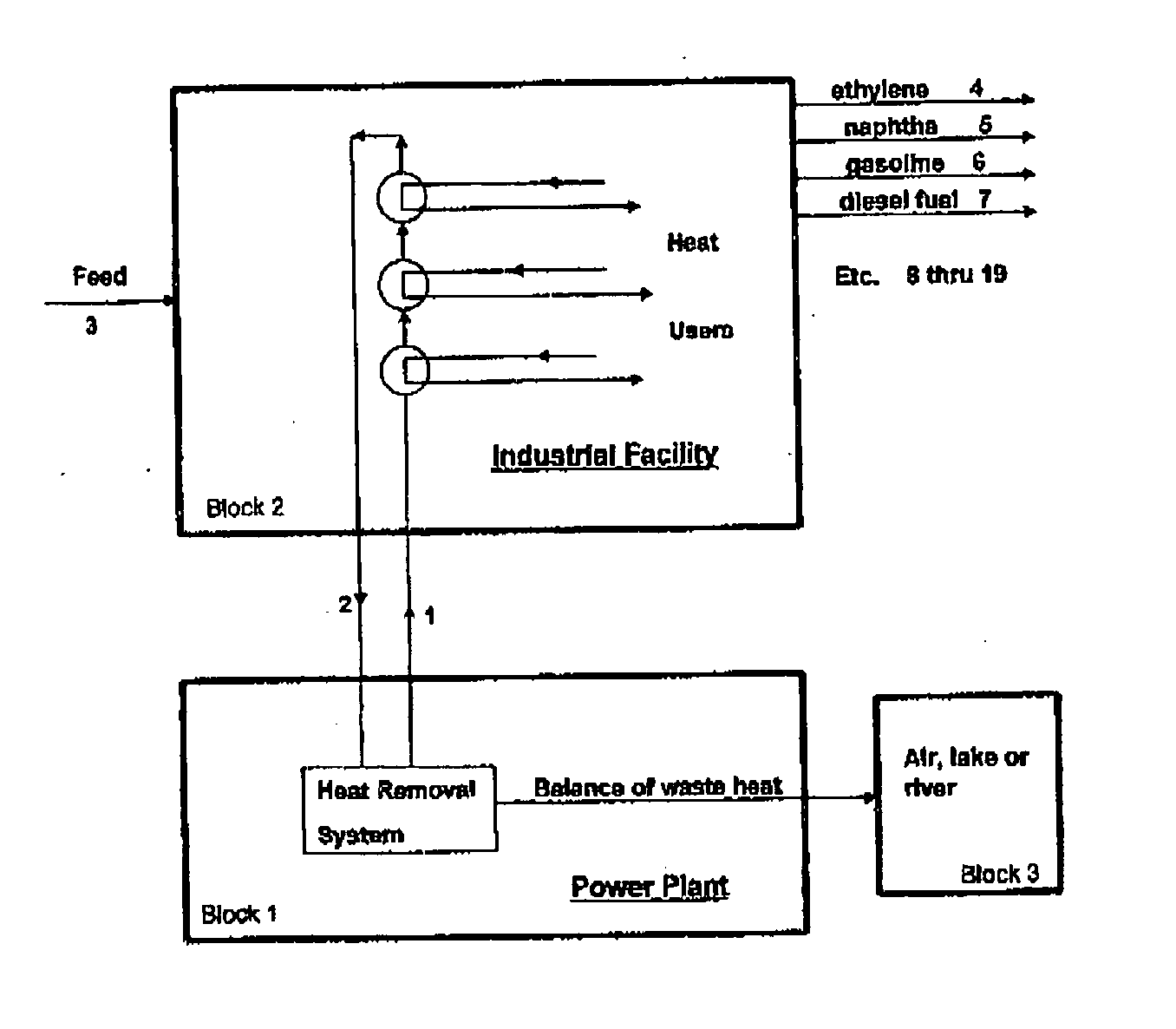

[0016]FIG. 2 is a schematic of Alternate No. 2 processing scheme.

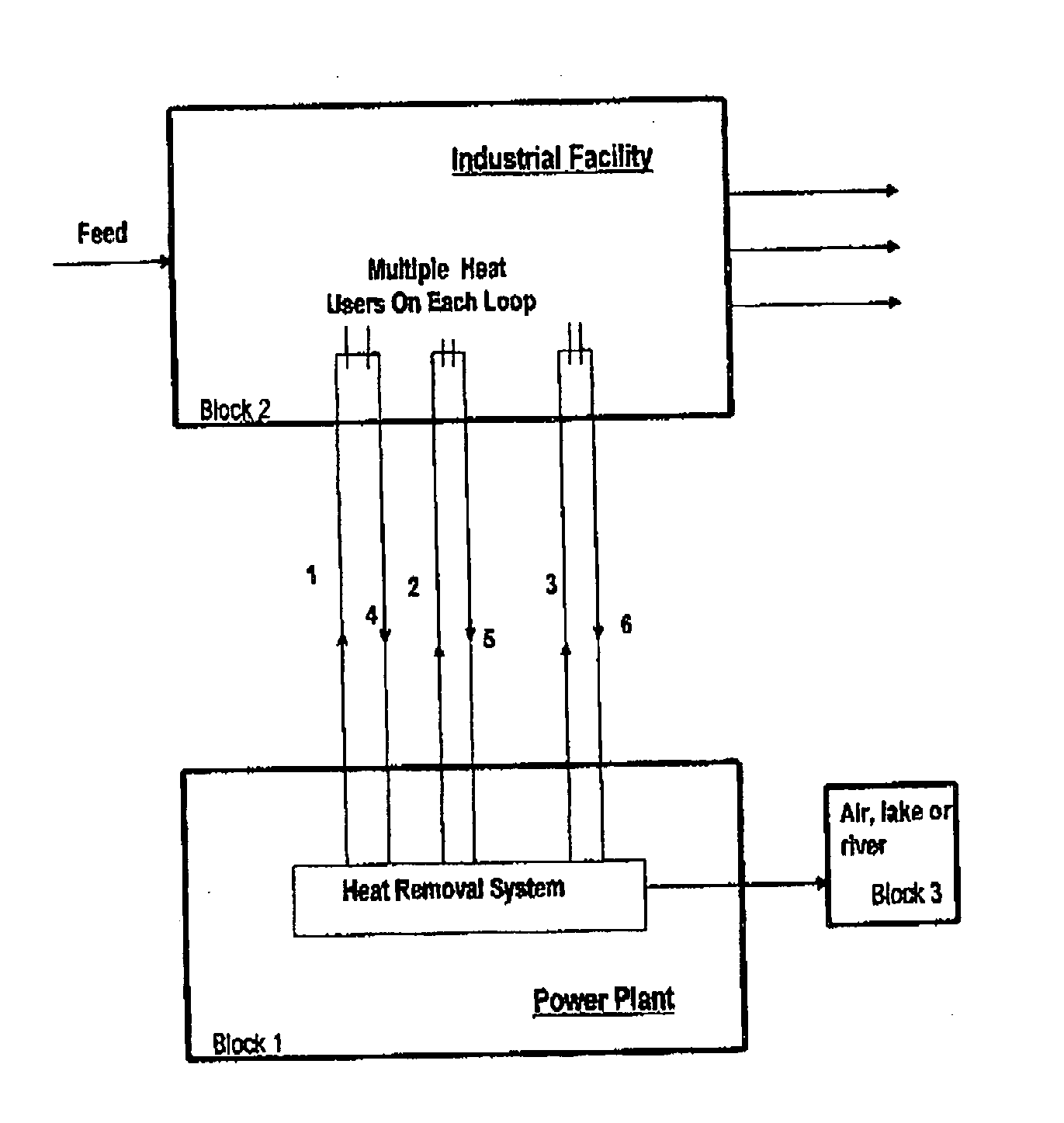

[0017]FIG. 3 is a schematic of Alternate No. 4 processing scheme.

DETAILED DESCRIPTION

[0018]The base processing scheme is depicted in drawing FIG. 1. Heat from a nuclear electric power plant (block 1) is diverted from some power generation and from the receiving lake or river (block 3) by material flowing hot to the industrial plant that requires the heat (block 2) through piping [1], and returning cooled in piping [2]. The flowing fluid is organic or inorganic vapor, liquid, molten fluid or slurry as required by the processes employed in the industrial plant, with necessary modifications to conventional reactor heat removal facilities in the nuclear plant design.

[0019]Using a petroleum refinery as an example, the amount of heat removed from the circulating hot fluid loop depends on the crude...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap