[0003]In contrast, the battery

test rig according to the invention has the

advantage that it is possible to test or examine batteries with an increased level of safety. According to the invention, high-efficiency cooling can be carried out in this case if necessary. This is achieved, according to the invention, by virtue of the fact that the battery test rig comprises a cooling apparatus which is connected to a regulation unit. A sensor device is connected to the regulation unit in order to monitor the battery. If the regulation unit detects that there is a hazard situation, it activates the cooling apparatus in order to cool the battery in order to thus prevent a critical battery state. The inventive external cooling of the battery thus makes it possible, on the one hand, to reduce a temperature of the battery and a pressure inside the battery, with the result that a critical situation can be avoided. The inventive use of the cooling apparatus also makes it possible to safely check research samples of batteries, in particular.

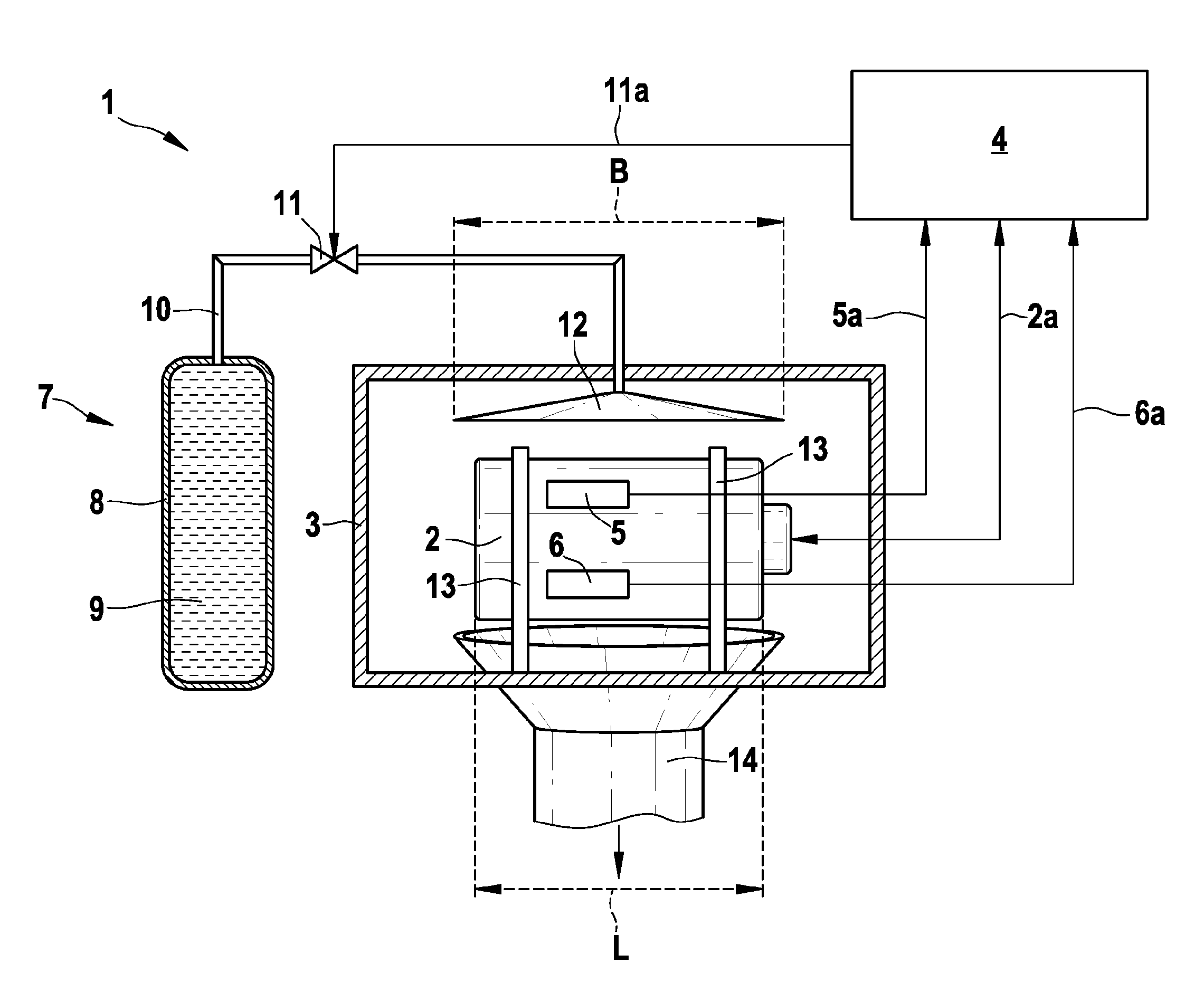

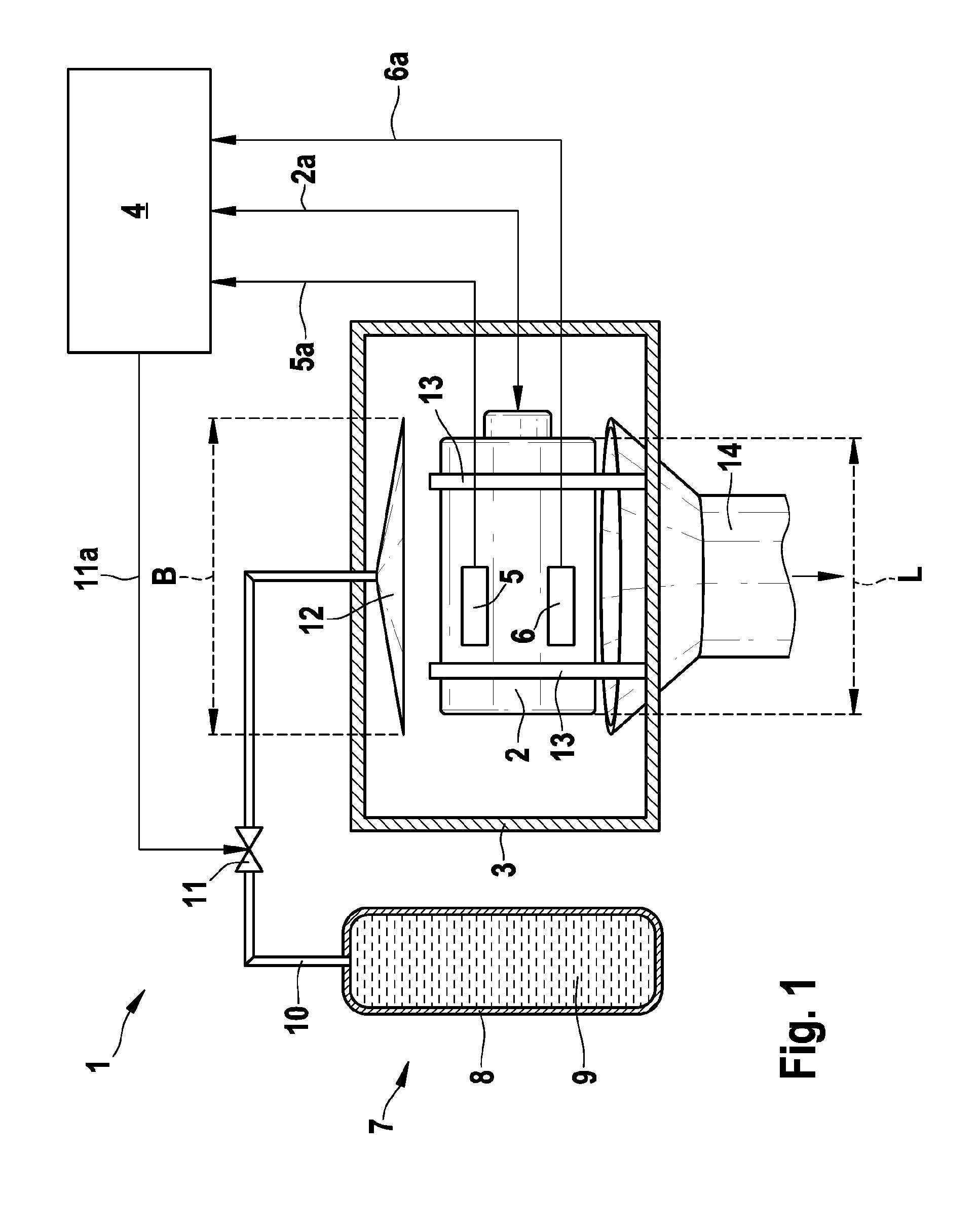

[0004]The cooling apparatus preferably comprises a

pressure vessel which is connected to a test cell, in which the battery is arranged, via a line. The cooling apparatus also comprises a switching valve which is connected to the regulation unit and is opened in a hazard situation in order to lead a

cooling medium stored in the

pressure vessel to the battery. As a result, a large area of the battery may be wetted with the

coolant, thus resulting in a high degree of

cooling efficiency. The

pressure vessel may also have a large supply of

cooling medium in order to be able to cool the battery for as long as possible.

[0005]The cooling apparatus more preferably comprises a

nozzle which is arranged in the test cell and makes it possible for the

cooling medium to expand in the vicinity of the battery. In this case, the cooling medium is sprayed onto the battery via the

nozzle in order to cool the battery over as large an area as possible. In this case, the

nozzle is preferably arranged above the battery, such that the cooling medium flows down along the outer periphery of the battery. In this case, the battery is more preferably arranged horizontally in the test cell, with the result that as large an area as possible can be wetted with cooling medium.

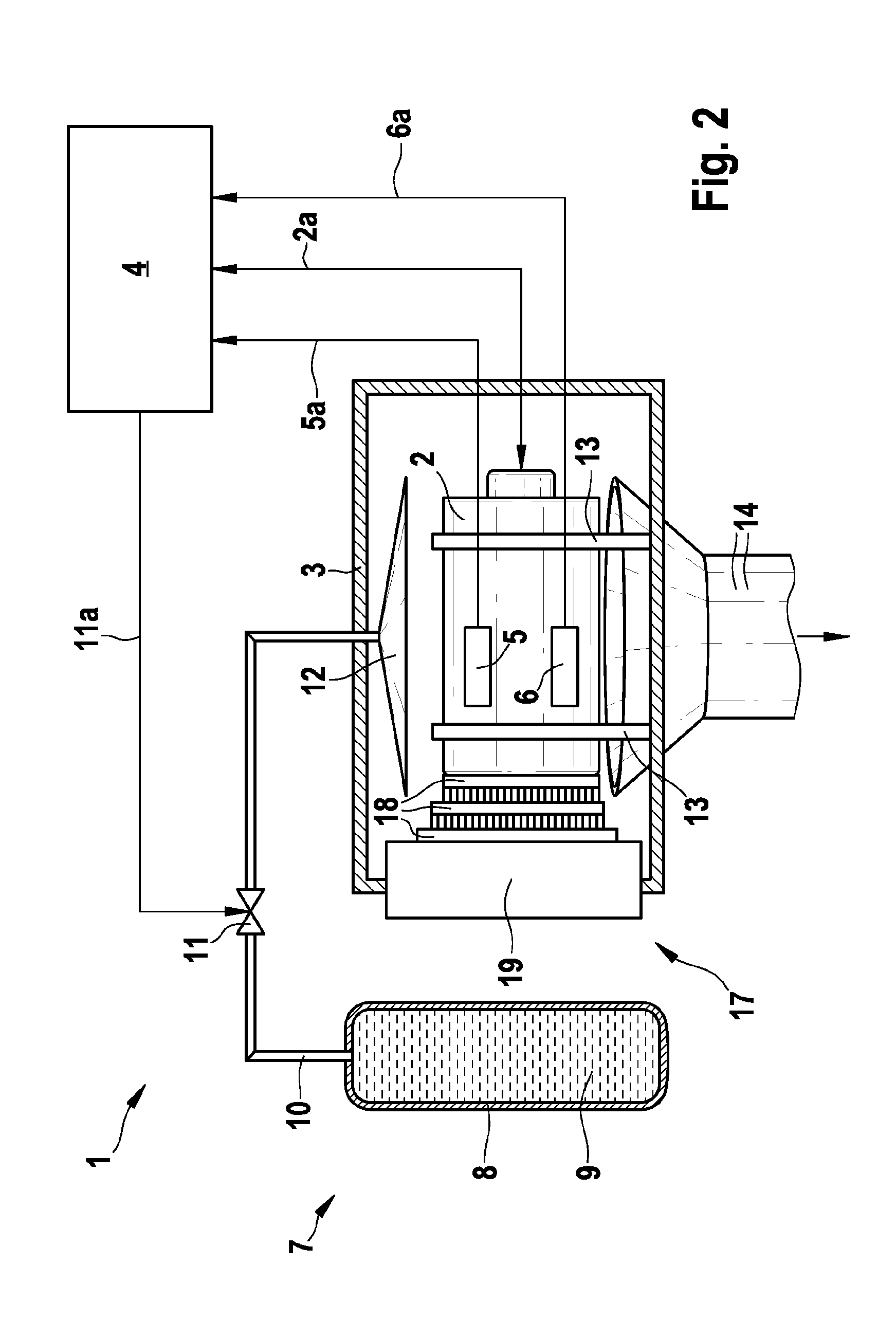

[0006]According to another preferred refinement of the present invention, the cooling apparatus comprises at least one Peltier unit which is arranged in the test center in order to cool the battery. The Peltier units consist of Peltier elements which are placed flat against one another, the Peltier elements consisting, for example, of two

semiconductor ceramics which are connected by

metal bridges. If a safety-critical state of the battery to be checked occurs, the Peltier unit is energized, as a result of which one of the

semiconductor ceramics is cooled, whereas the other is heated. In this case, the cooling apparatus particularly preferably comprises a multiplicity of Peltier units which are arranged in the form of a

pyramid. This makes it possible to achieve a plurality of cooling stages, such that even large temperature differences of up to 70

Kelvin and temperatures below 0° C. can be achieved. In this case, the last stage of the multiplicity of Peltier units is preferably connected to a

heat exchanger which transports the

waste heat from the test cell.

[0007]The sensor device preferably comprises a temperature sensor and / or a

pressure sensor and / or a

force sensor, in particular a strain gage, and / or a distance sensor. In this case, the sensors are preferably arranged on an outer side of the battery. As a result, a simple structure of the battery test rig is achieved and, in particular, a multiplicity of batteries can be checked in a short time. It is noted that a plurality of different sensors are particularly preferably arranged on the battery. Alternatively, it is naturally also possible to arrange a plurality of identical sensors on a battery to be examined.

[0008]The battery test rig preferably also comprises a suction apparatus in order to suction gases or other media from the interior of the test cell. On the one hand, this results in toxic gases, for example, being able to be safely suctioned from the test cell and, on the other hand, avoids a disproportionate

pressure increase inside the test cell. A vacuum can also be generated in the test cell as a result.

Login to View More

Login to View More  Login to View More

Login to View More