Cooling apparatus and method

a technology of cooling apparatus and cooling method, which is applied in the direction of lighting and heating apparatus, fluid pressure control, instruments, etc., to achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Further Options and Preferences

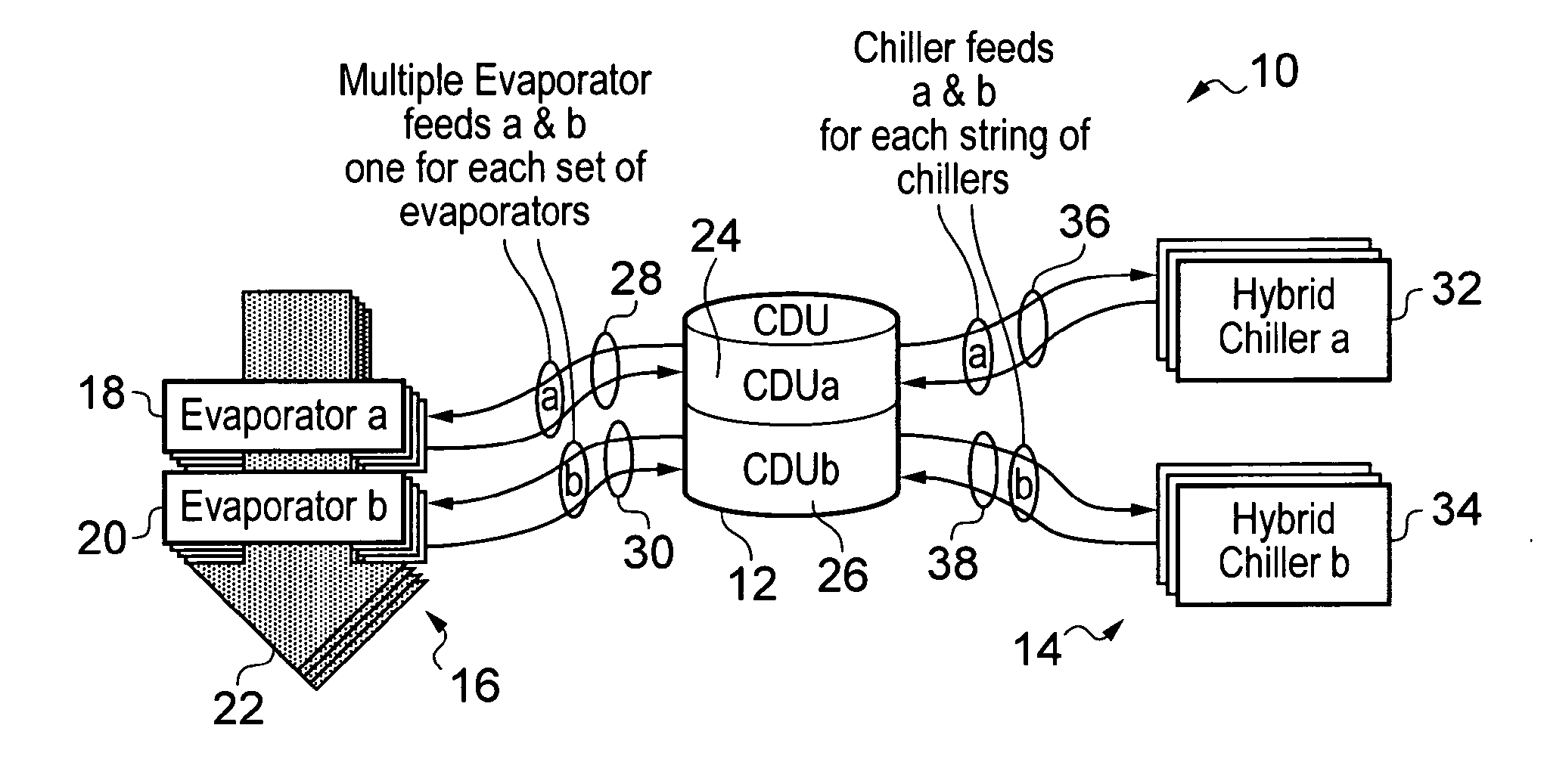

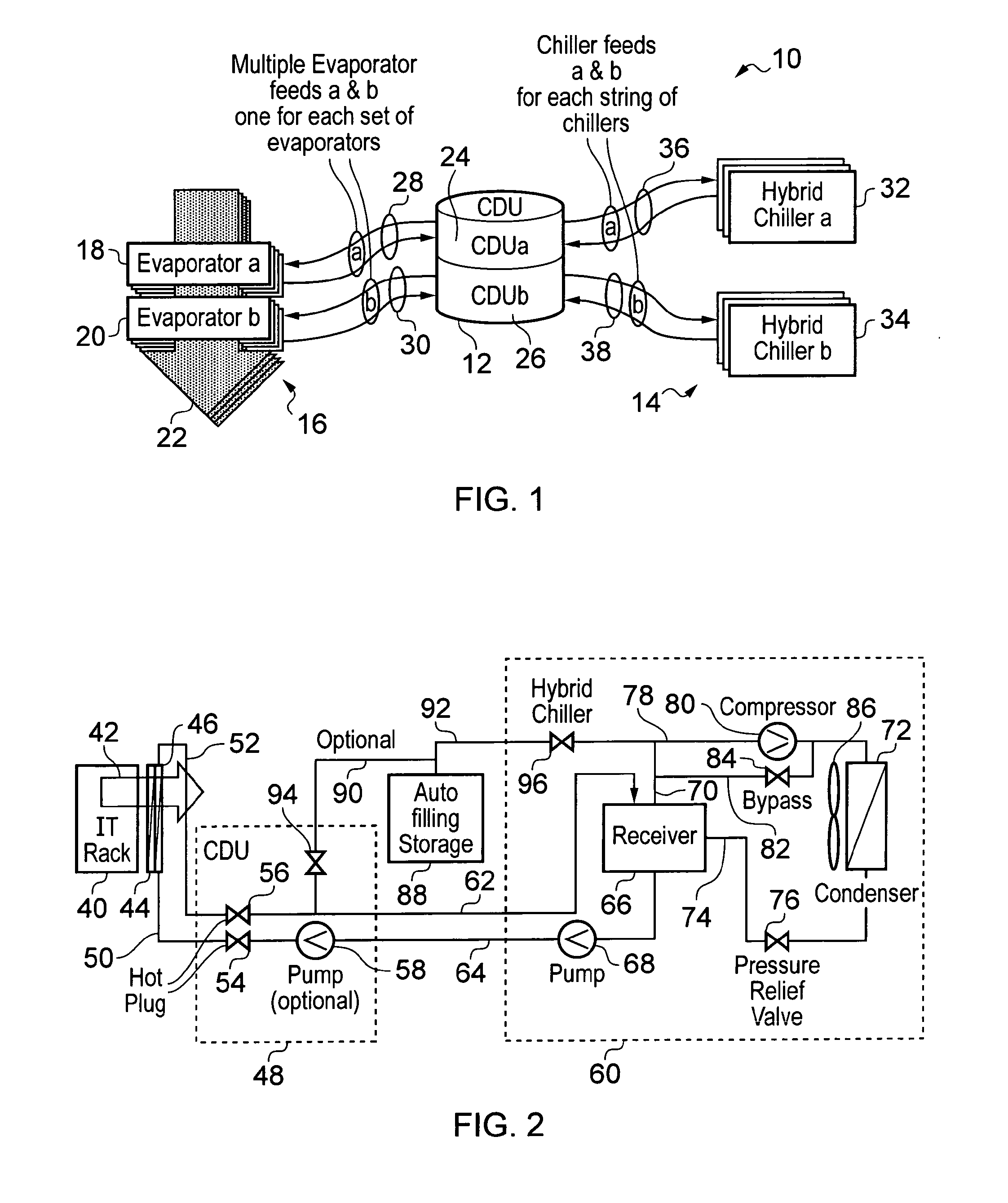

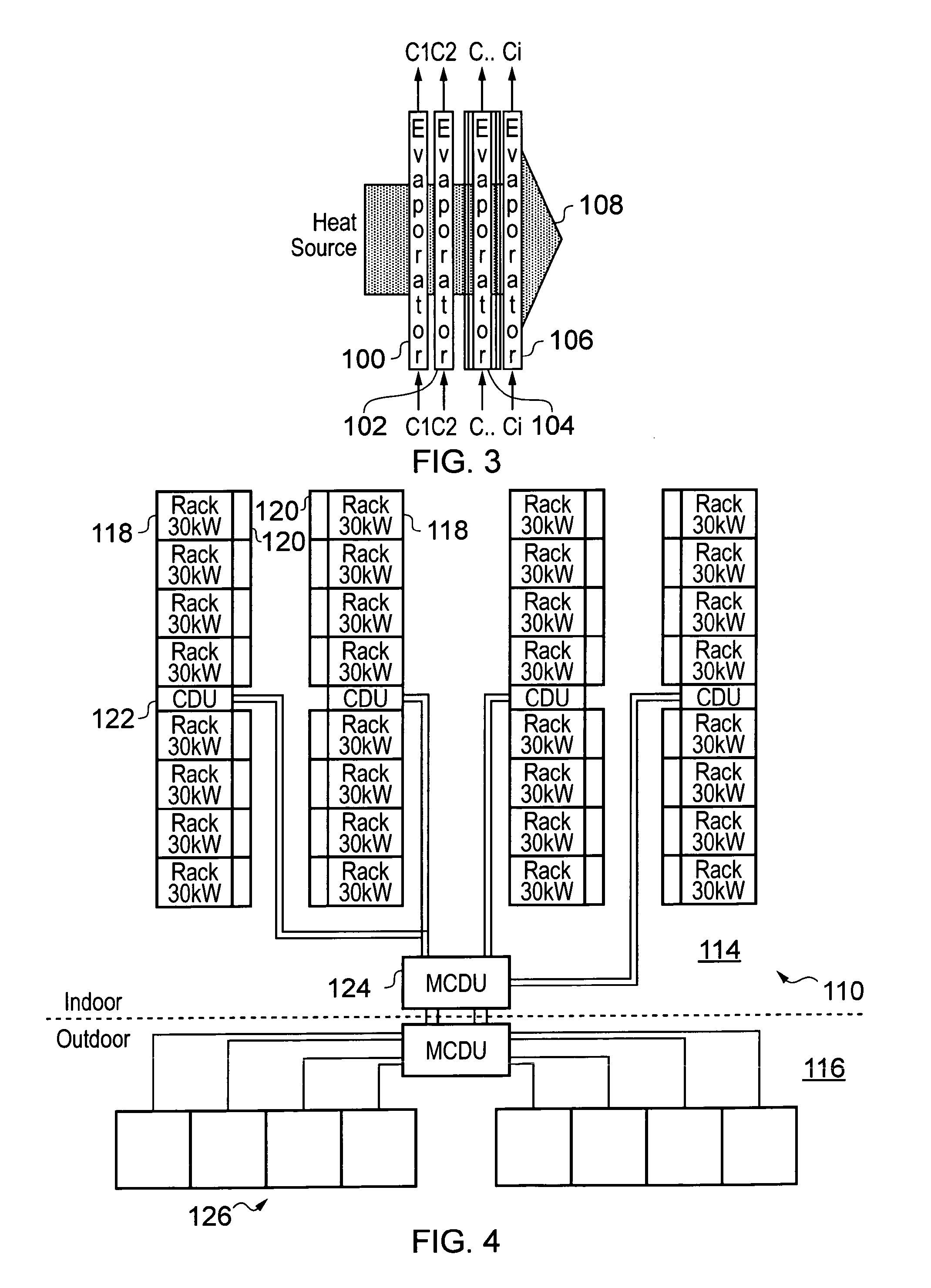

[0040]The present invention may provide a flexible solution to the problem of cooling a data centre efficiently. The invention may utilize natural and non-water-based refrigerants. The invention may provide scalable apparatus, e.g. to enable tailored control of cooling system, e.g. in accordance with a business plan or proposed development. The scalability may also enable increases in the overall power density of a rack to be catered for, thus supporting the development of high power density blade servers and network equipment.

[0041]By providing heat exchangers associated with particular heat sources, the invention may limit or remove the need for forced airflow, which is standard in conventional cooling solutions. Similarly, the invention may remove the need for computational fluid dynamics (CFD) analysis of air flow patterns within a space to be cooled, and particularly the change of such patterns during operation, service and maintenance. This may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com