Method for Controlling a Gas Burner and a Hob with Several Gas Burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

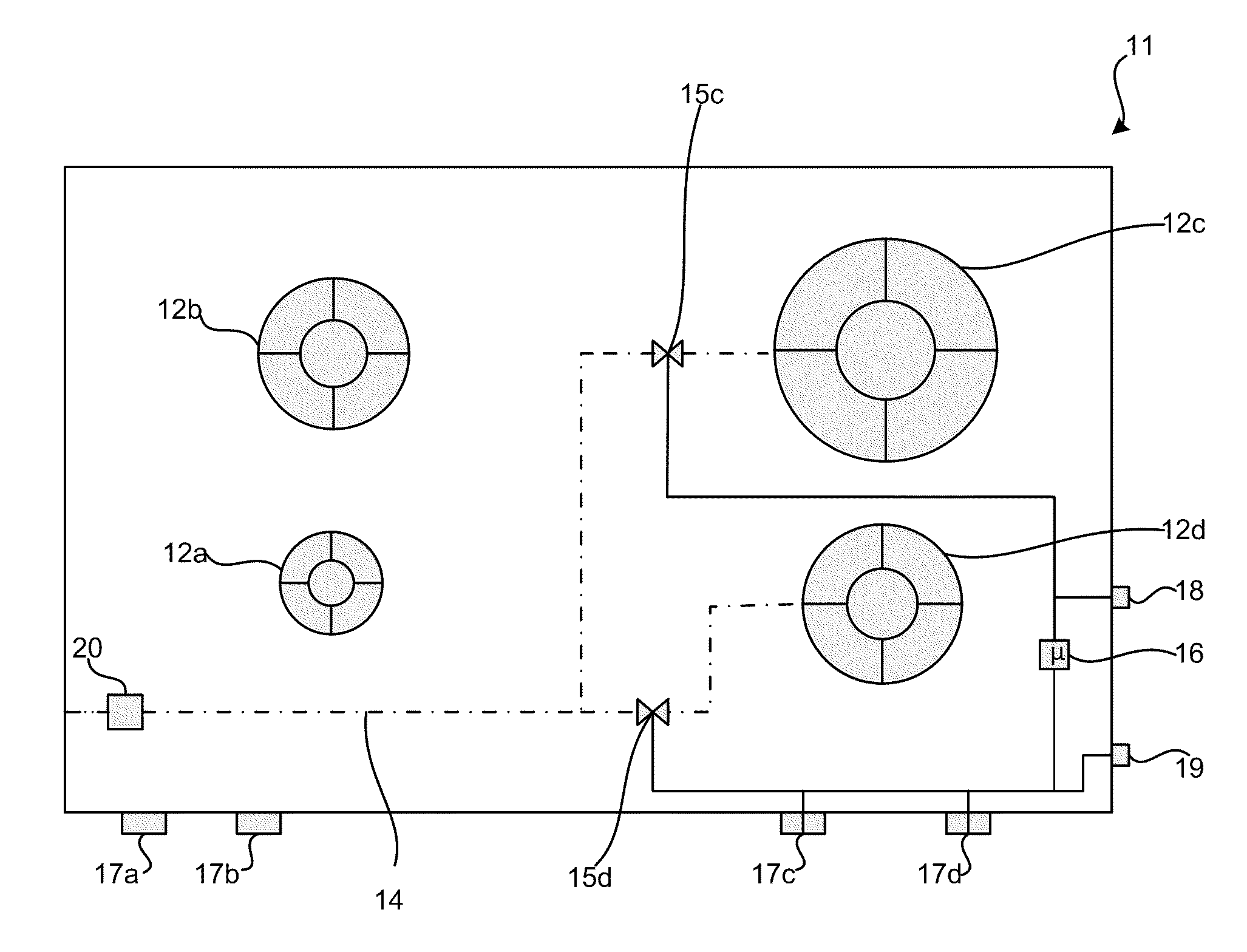

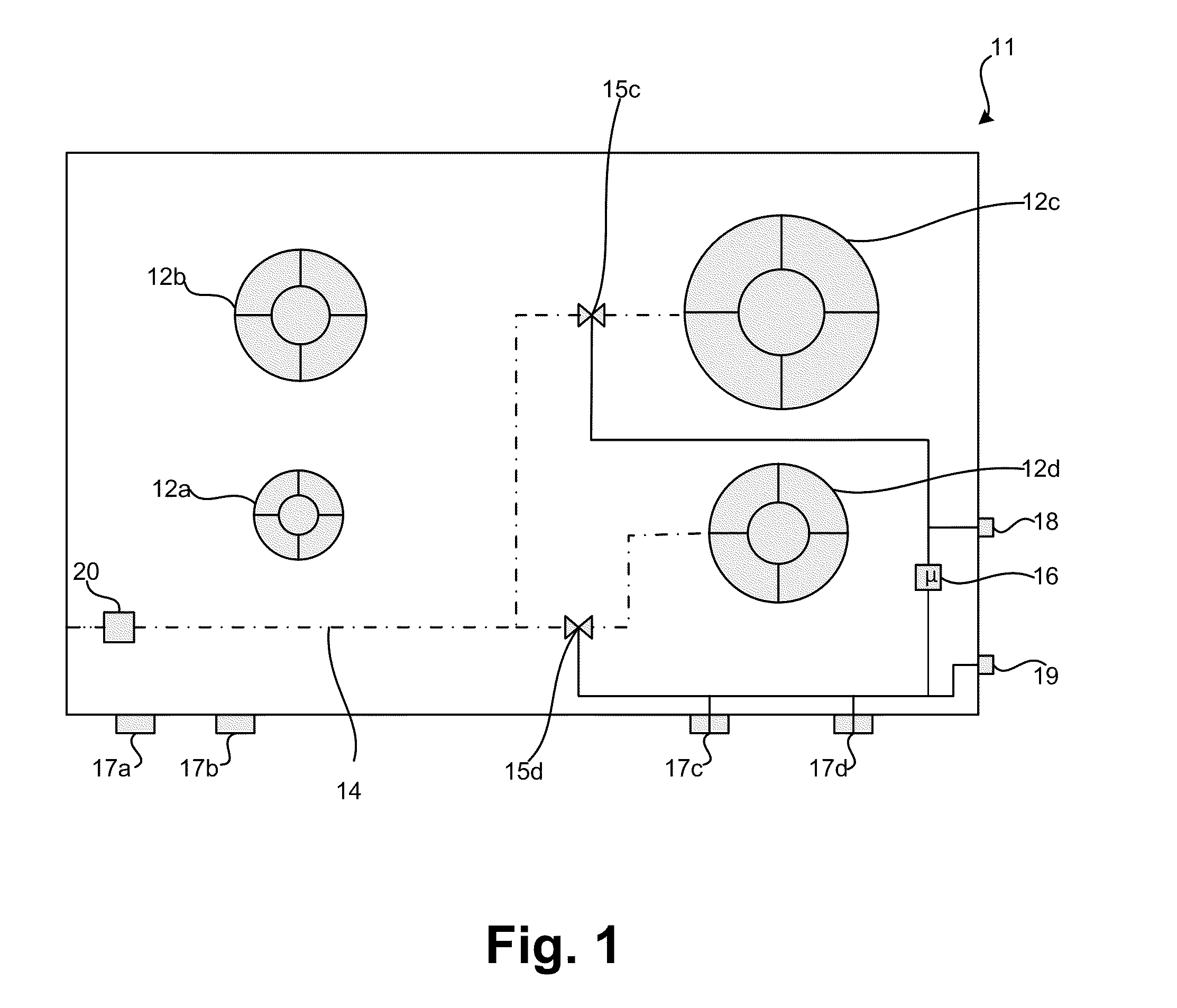

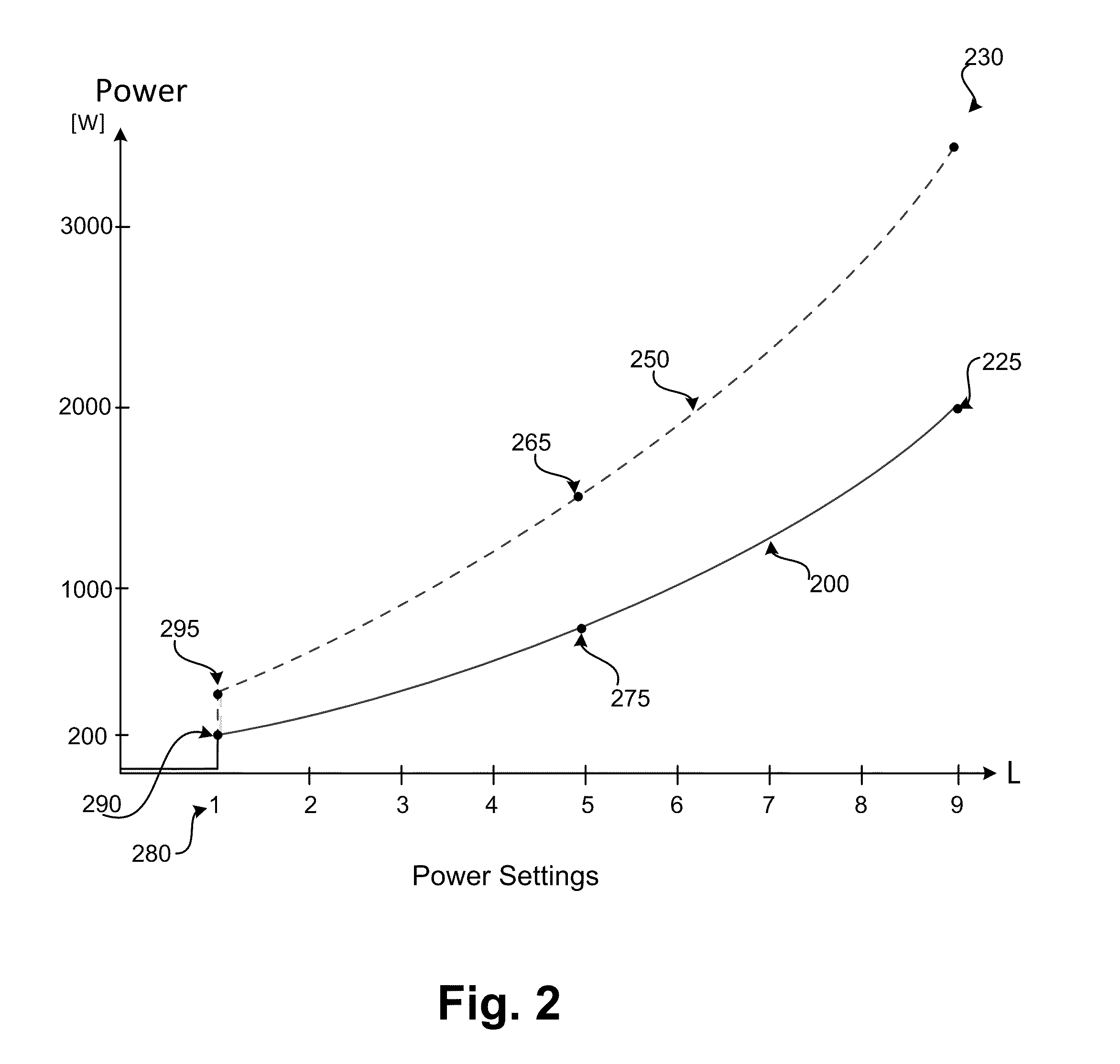

FIG. 1 shows a gas hob 11 in a schematic plan view in accordance with one embodiment of the invention. The gas hob 11 has four gas burners 12a to 12d, in a manner known per se. Here the front left gas burner 12a is a relatively small gas burner, for example for a power range of 150 W to 1200 W. The rear left gas burner 12b is a medium-sized gas burner intended and designed for a power range of 200 W to 2000 W. The rear right gas burner 12c is a relatively large gas burner designed for a power range of, for example, 500 W to 3500 W. The front right gas burner 12d is a further medium-sized gas burner that, however, is designed in accordance with an embodiment of the invention and can also operate in accordance with the invention. It can operate firstly in a low power range, which as for the gas burner 12b extends from 200 W to 2000 W, with 200 W being the lowest emitted continuous power or the lowest operating power, and with 2000 W being the highest power in the maximum setting of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com