Portable spreader for particulate matter

a technology of particulate matter and spreader, which is applied in the direction of centrifugal wheel fertilisers, ways, constructions, etc., can solve the problems of high power, easy jamming of impellers with a vertical axis of rotation, and generating undesirable nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

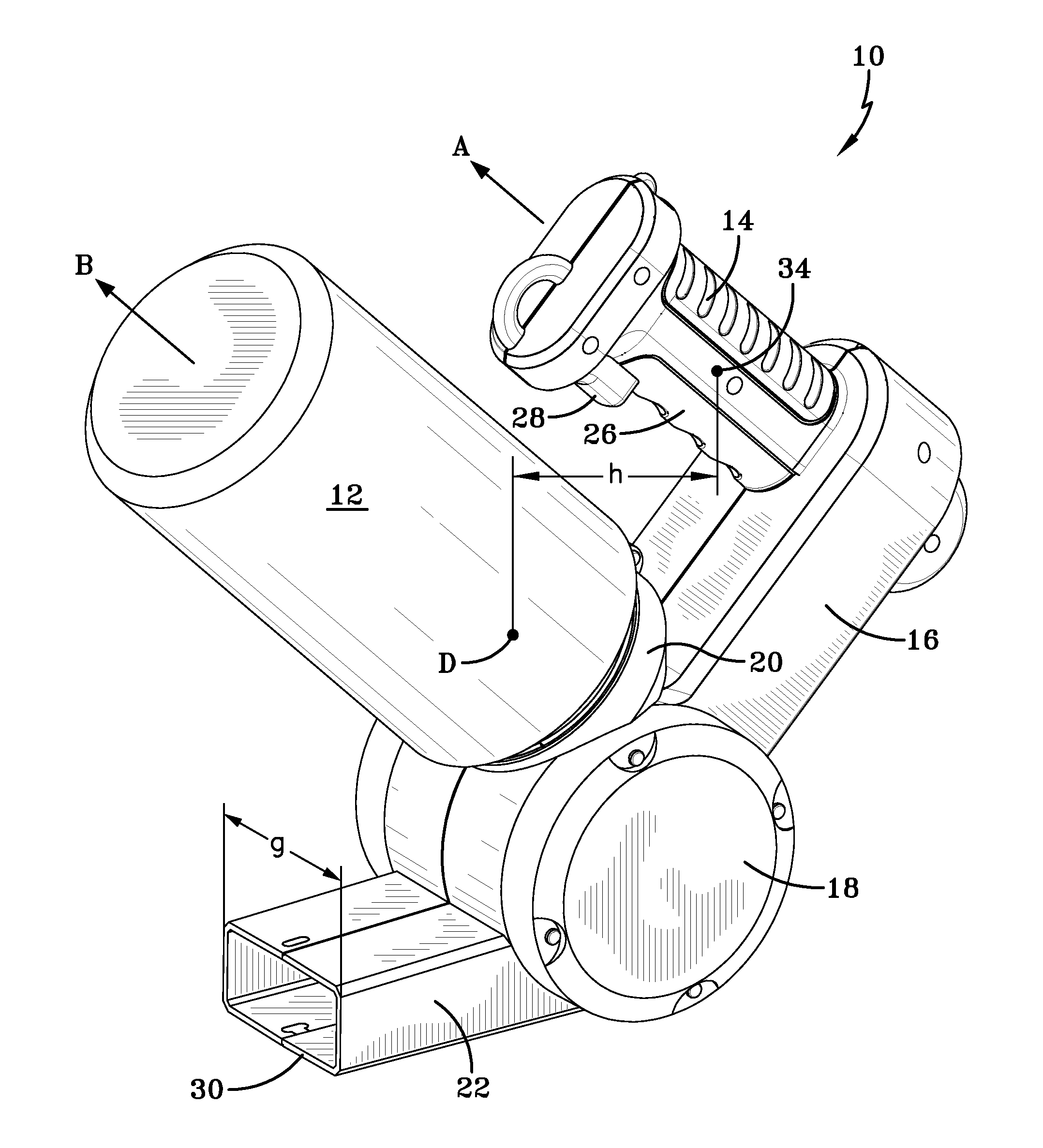

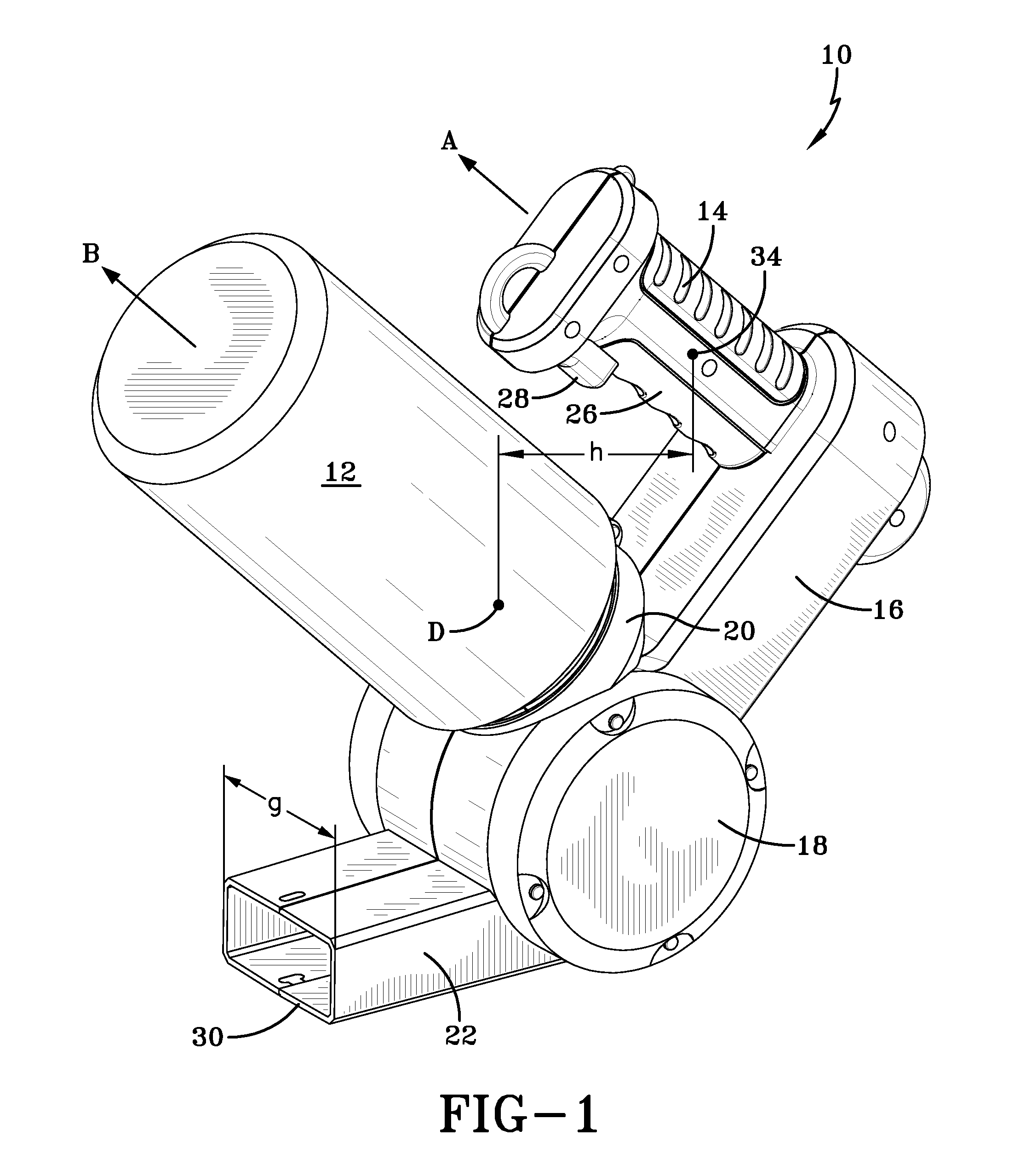

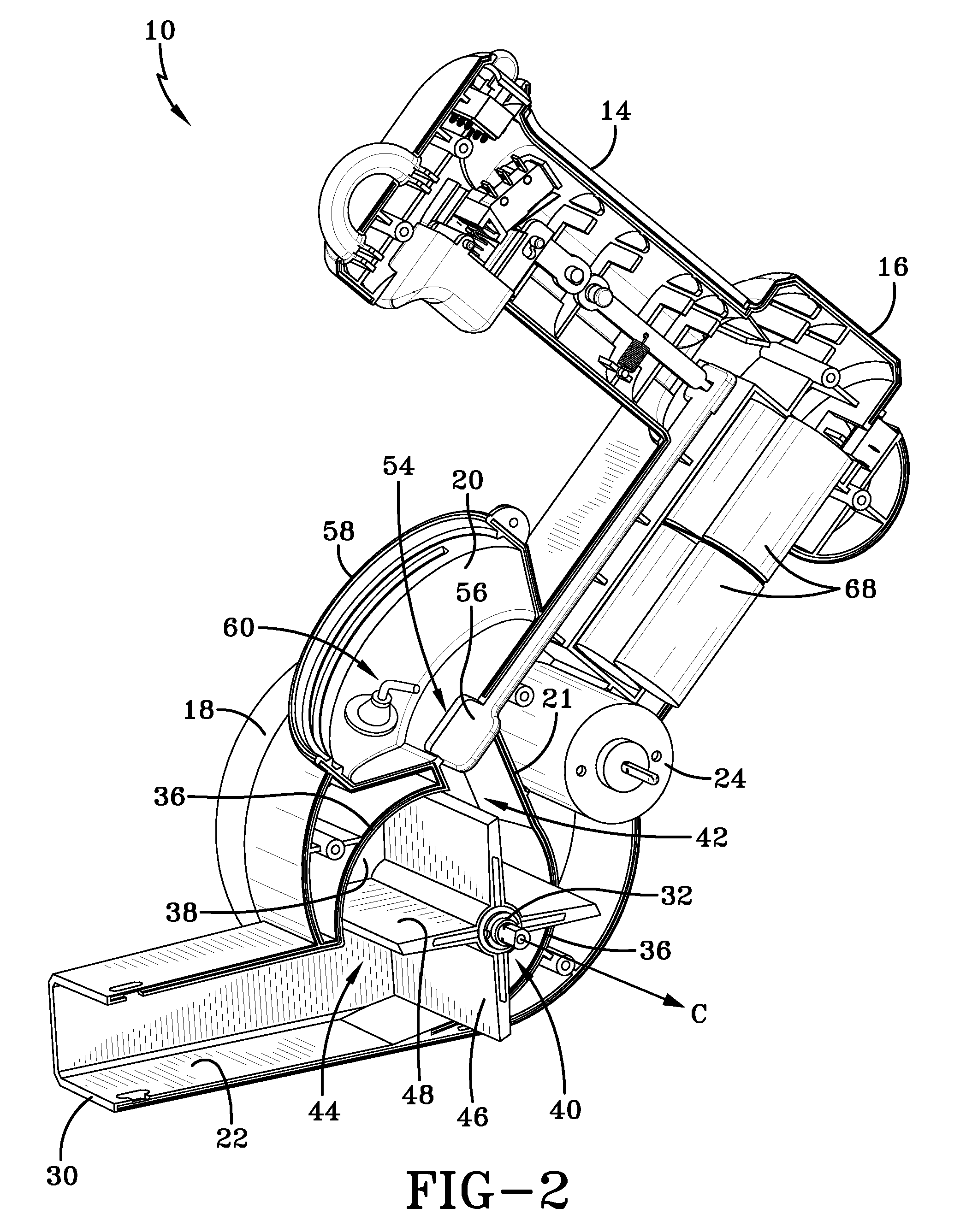

[0028]FIG. 1 is a perspective view of an embodiment of a gravity-feed portable spreader 10 for spreading particulate matter. Spreader 10 may be used to distribute or spread particulate matter. By way of example, and not limitation, particulate matter may include plant seeds, grass seeds, fertilizer, calcium chloride, sodium chloride (de-icing salt), herbicides, etc. The size of the individual particles in the particulate matter may vary from small, such as powdery materials, to larger materials such as sodium chloride crystals, or even particles larger than sodium chloride crystals. Spreader 10 may include a canister 12, a handle 14, a first housing 16, a second housing 18, an intake housing 20, and an exit channel 22.

[0029]Canister 12 may function as a storage container for the particulate matter to be spread. Canister 12 may be formed integrally with intake housing 20 or may be removably connected to intake housing 20. For example, canister 12 and intake housing 20 may include com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com