Architectural heat and moisture exchange

a technology of architectural heat and moisture exchange, applied in indirect heat exchangers, lighting and heating apparatus, heating types, etc., can solve the problems of undesirable loss of energy and humidity from the building, inability to perform significant moisture exchange, and exhaustion of previously heated or cooled air from the building spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

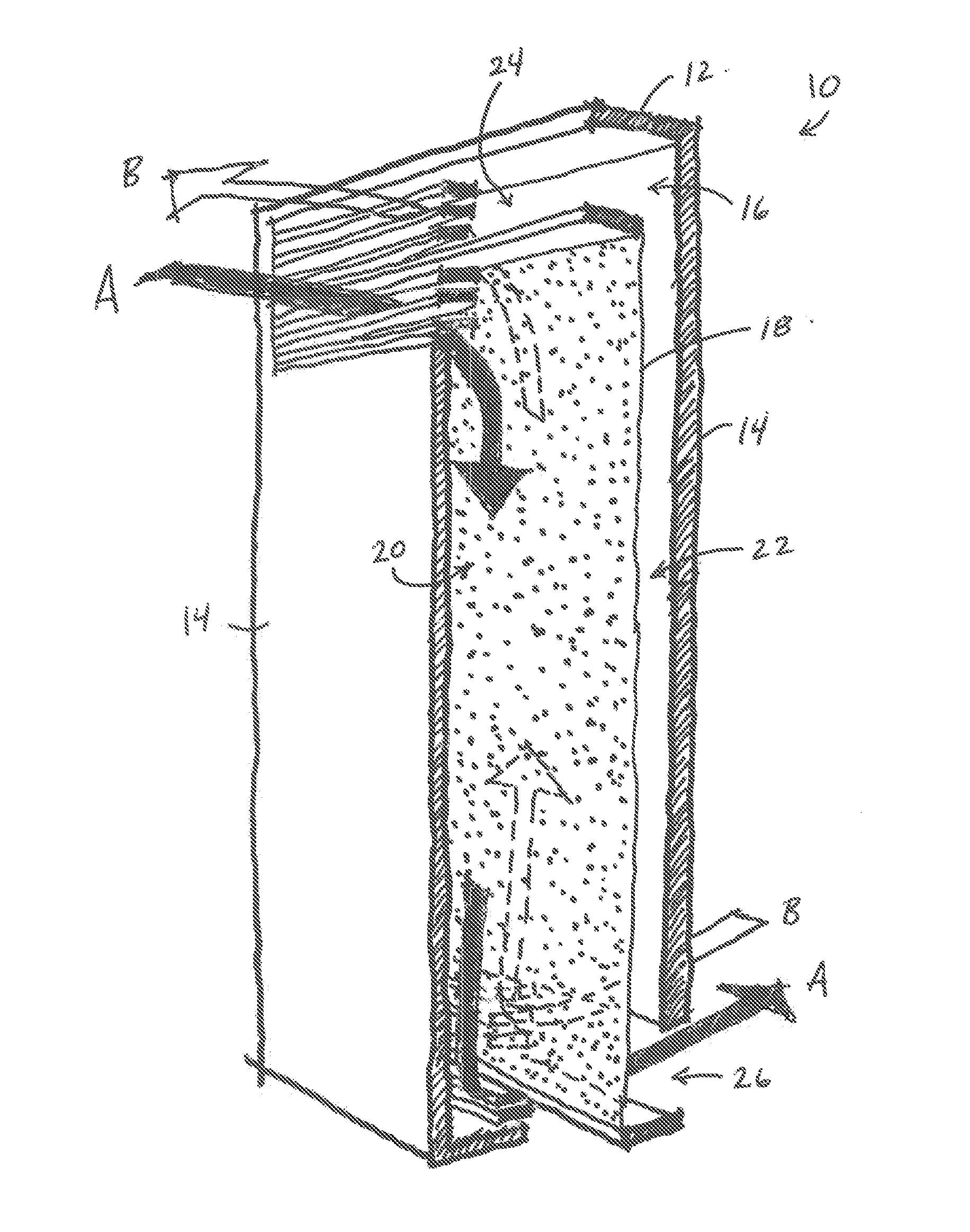

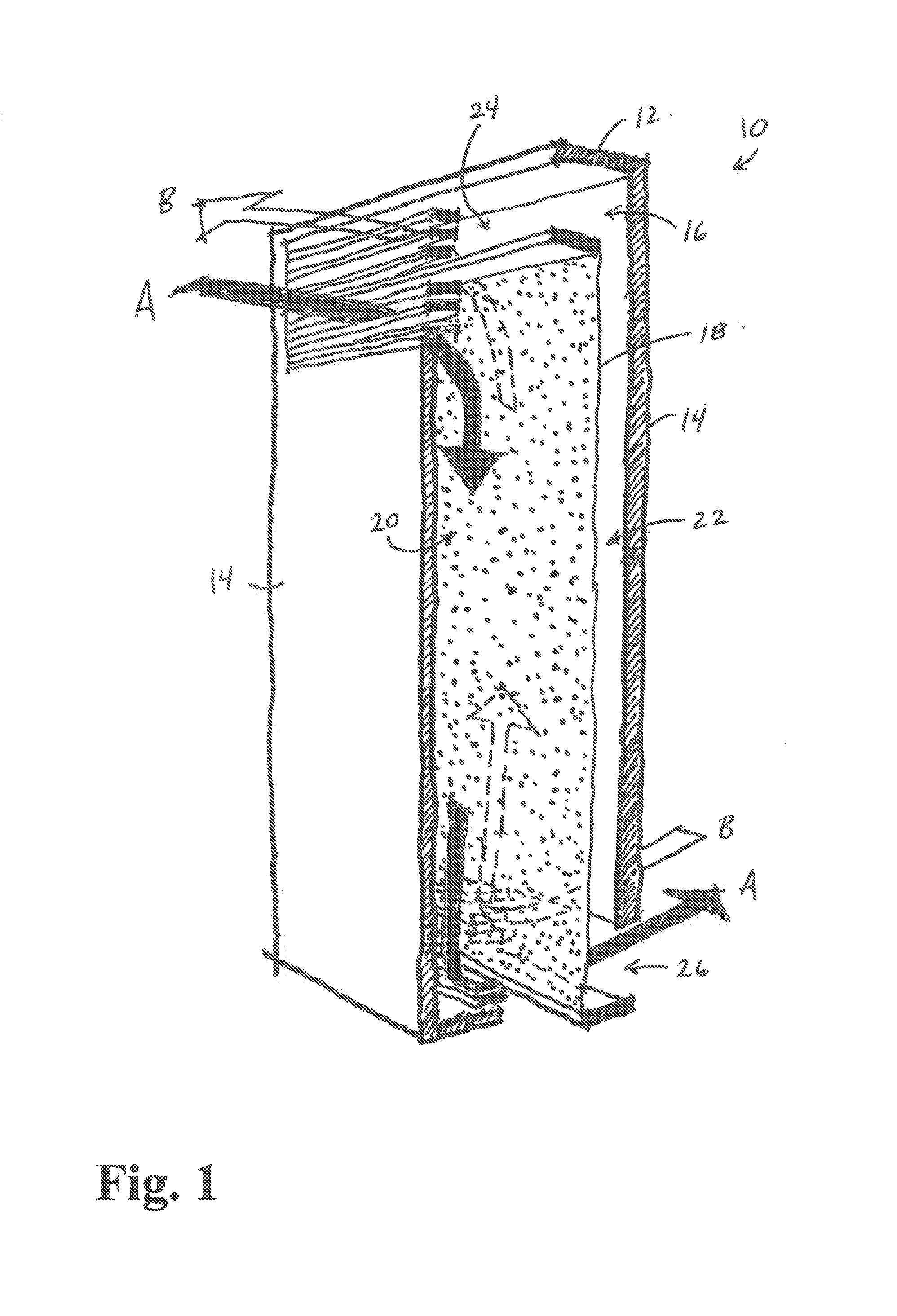

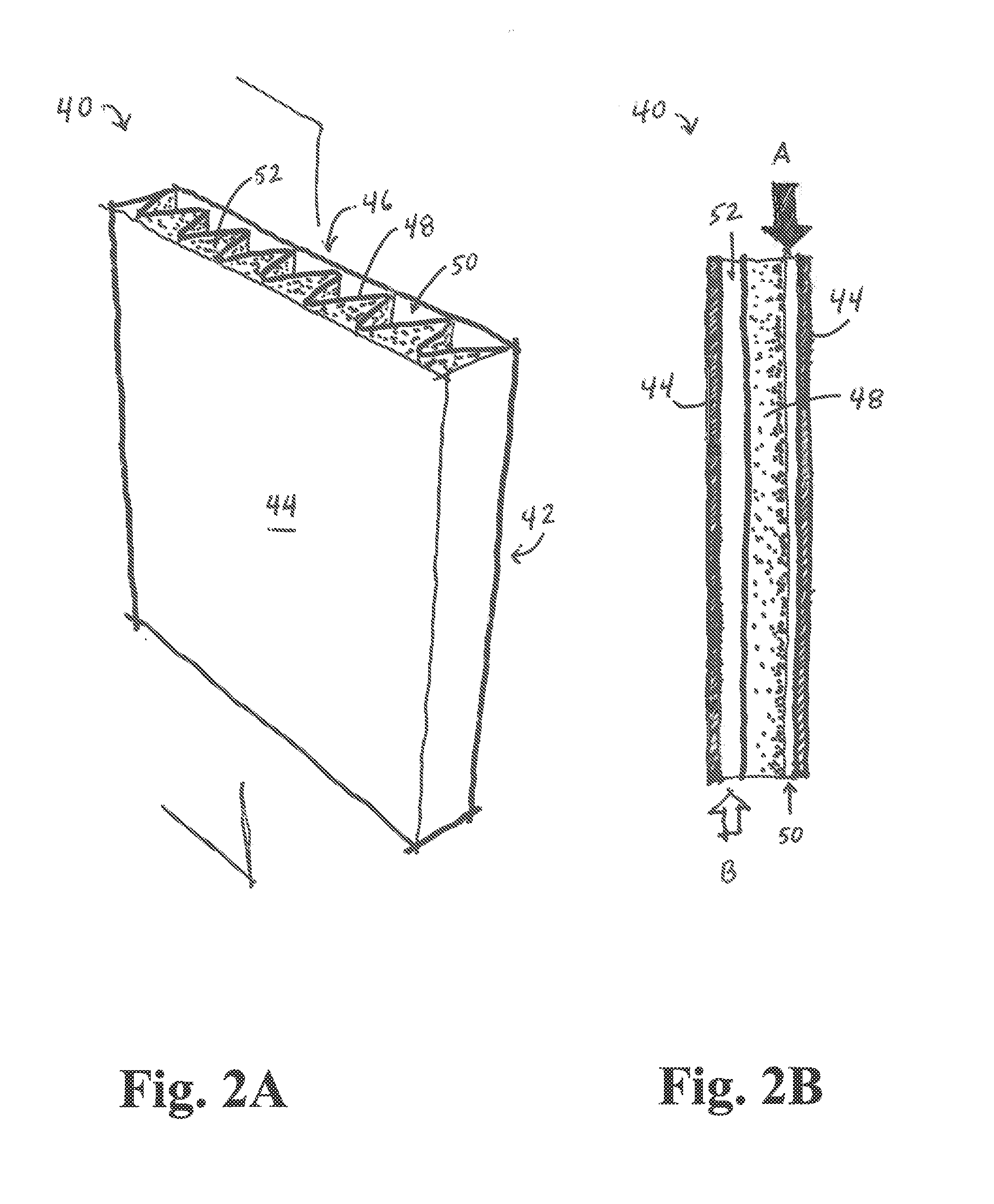

[0035]The present teachings relate to improved methods and apparatus for recovering energy and / or moisture as air is added to and exhausted from an enclosed space. These teachings may be combined, optionally, with apparatus, methods, or components thereof described in U.S. Pat. No. 6,178,966 to Breshears. However, the present teachings expand upon the prior art teachings by disclosing novel improvements such as an exchanger incorporated into an opaque exterior building element. These and other aspects of the present teachings are described in detail in the sections below.

[0036]This description discusses some of the basic features of heat and moisture exchangers according to aspects of the present teachings, and focuses particularly on incorporating exchangers into various external building elements, such as walls, foundations, roofs, and slab floors configured to divide an enclosed space from the ambient exterior and collectively referred to as a building enclosure system. See FIGS....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com