Method of producing an upgraded bio-oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0095]The Examples defined in this section are merely examples of the many possible configurations for the present invention. More particularly, the exemplary reactor types and sizes, along with the amounts of the various reactants, catalysts, and auxiliary components, are contemplated to vary depending on the industrial setting for which they are utilized. Accordingly, the wet biomass can be processed in any amount desired, and the other components and size and design of reactors can be modified accordingly.

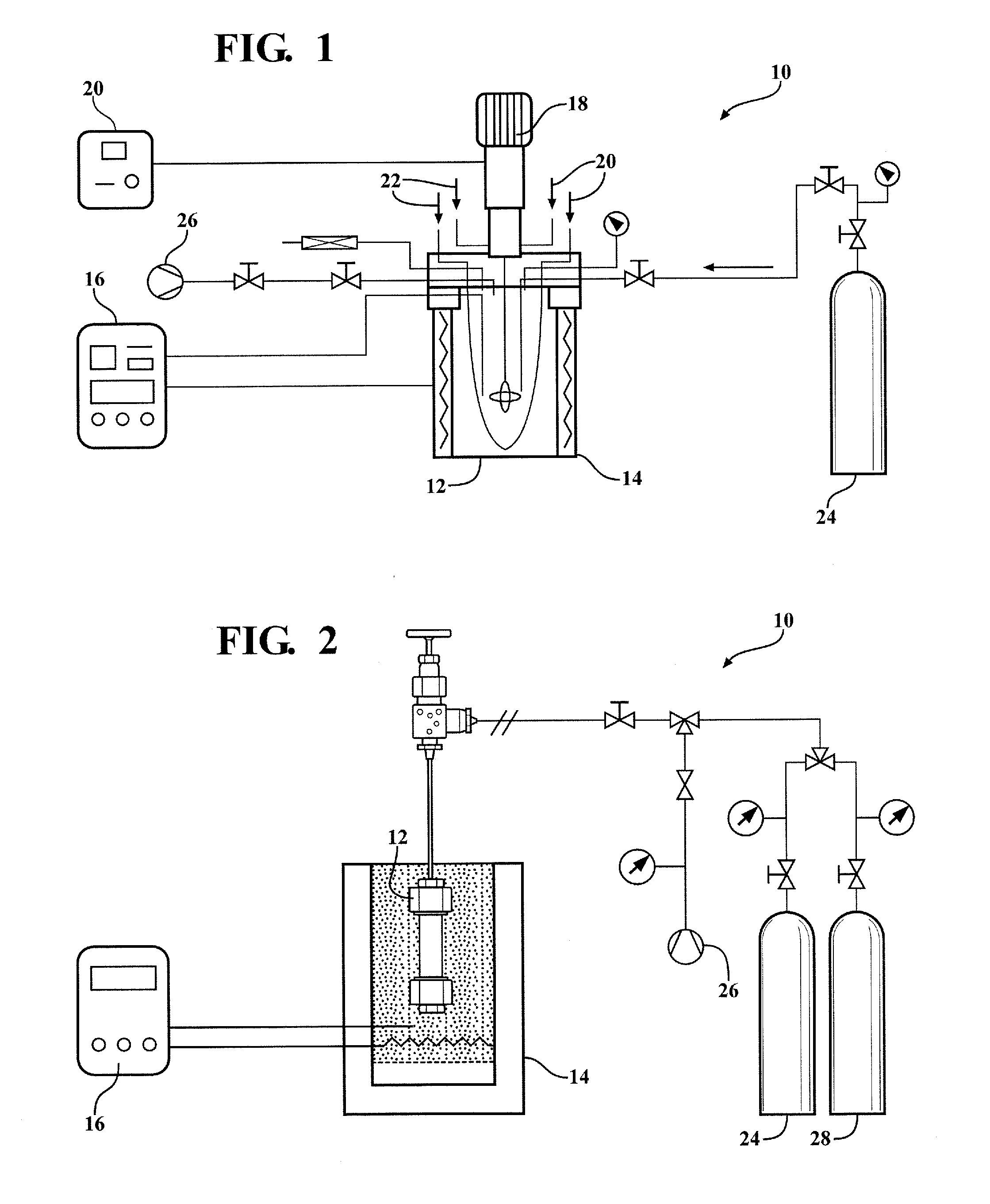

[0096]316-stainless steel reactors (herein after “crude bio-oil reactors”) are used, which allow for the recovery and analysis of both the crude bio-oil and the gas above the crude bio-oil in a single run. The crude bio-oil reactors, illustrated in FIG. 1, may comprise an 8-in length of ¾-in O.D. tube having a first end opposite and spaced from a second end in addition to a wall thickness of 0.065 inches. Additionally, the crude bio-oil reactors have a volume of 31 ml. A cap is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com