Quenching device and quenching method

a technology of a quenching device and a quenching method, which is applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problem that leakage problems are necessarily presen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

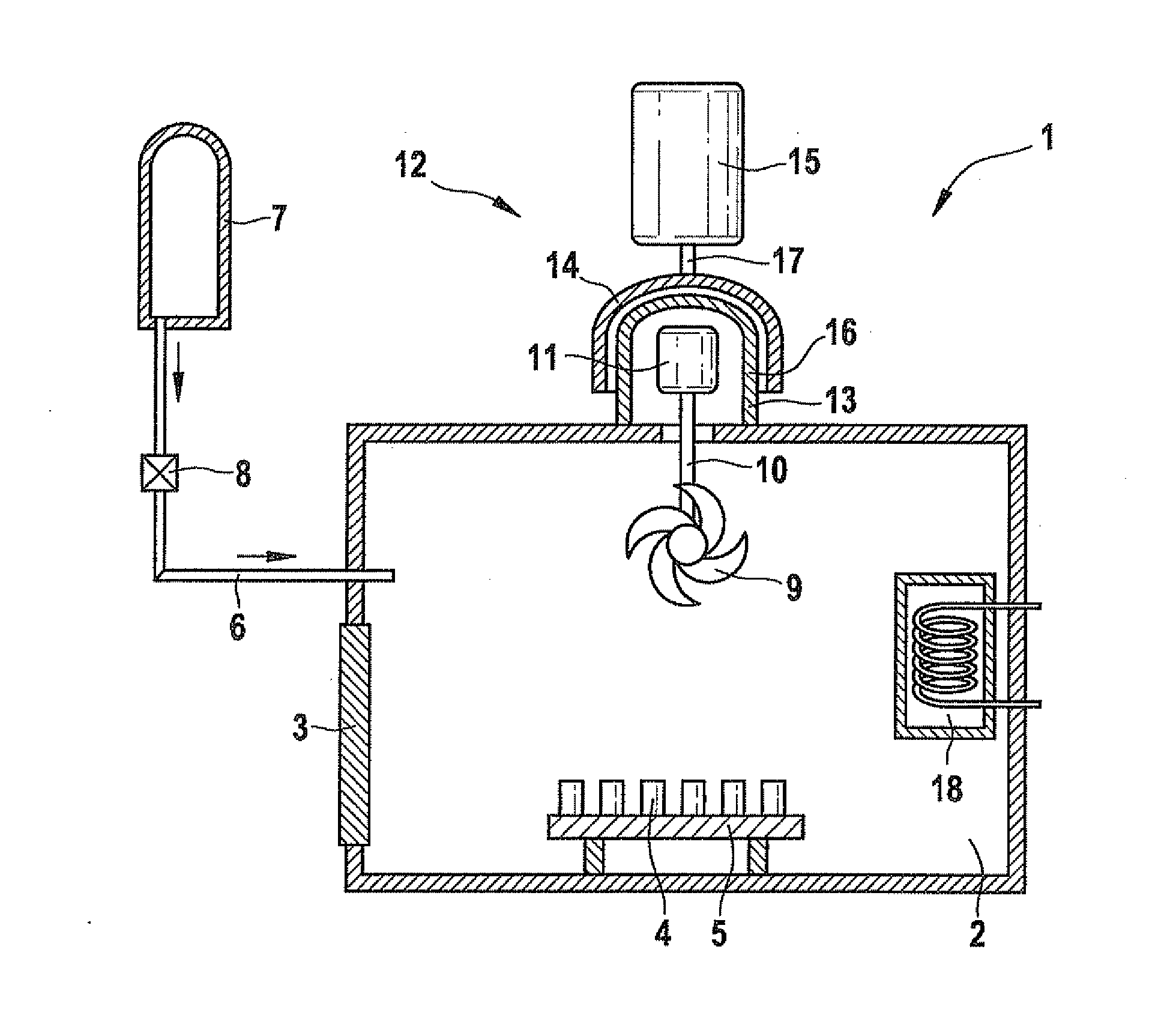

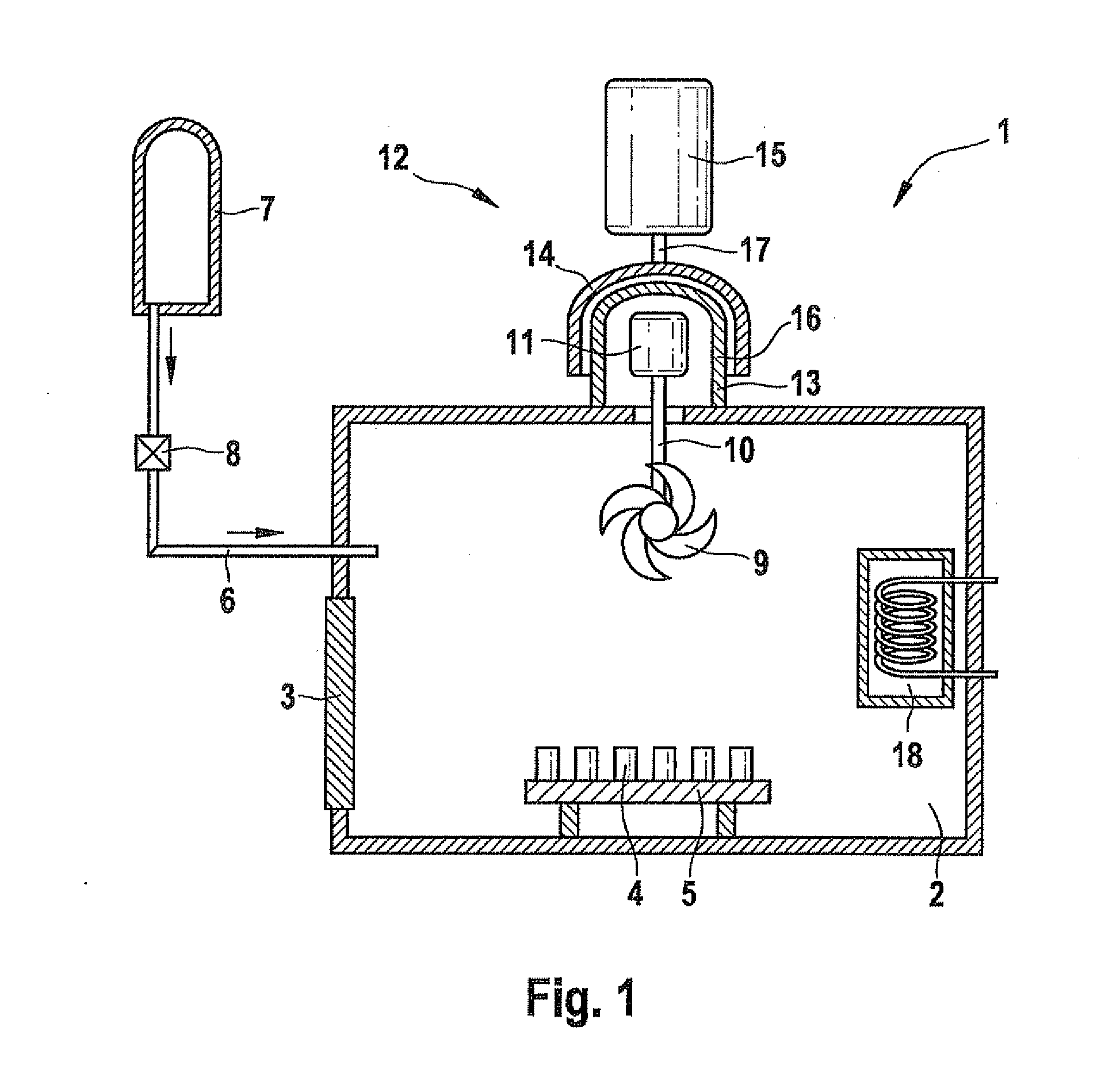

[0021]FIG. 1 shows a possible specific embodiment of a quenching device 1. In the depicted exemplary embodiment, quenching device 1 has a single chamber 2 that can be flooded with quenching gas. A floodable chamber in the form of a flow channel as shown in EP 1154 024 B1 does not exist here, but can be provided if needed.

[0022]Chamber 2 has a loading door 3 that can be sealed in pressure-tight fashion, through which chamber 2 (here the quenching chamber) can be loaded with material 4 that is to be quenched. For this purpose, material 4 that is to be quenched, which in the depicted exemplary embodiment is made up of steel workpieces, is placed on a charging rack 5 that, using suitable transport devices, can be transported into chamber 2 under a vacuum atmosphere and then transported out of said chamber after the quenching process.

[0023]An oven (not shown) for the preliminary heat treatment of quenching material 4 is standardly situated in front of loading door 3.

[0024]A quenching gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metallic bond | aaaaa | aaaaa |

| Magnetism | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com