Sustainable coated corrugated fiberboard container

a corrugated fiberboard and container technology, applied in the field of packaging, can solve the problems of depleting natural resources in the environment, sf-grade solid fiberboard currently used, and more expensive than common commercial grade fiberboard, so as to reduce the environmental footprint of military rations, reduce negative environmental impacts, and enhance end-of-life disposal capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0035]The containers are preferably constructed from corrugated fiberboard consisting of 55 pound or 69 pound linerboard facings with a 30 pound corrugating medium material forming a balanced single wall C-flute structure. A water-resistant coating is applied to the linerboard facing material, for example, coatings manufactured under the Spectra-Guard™ name by the Spectra-Kote™ Corporation, in particular its sg48m™ coating. Additionally, WAM is applied to the 30 pound fiberboard forming the C-flute structure of the preferred fiberboard material in order to improve its water resistance. In the first embodiment disclosed infra., an additional corrugated insert having a B-flute structure forms the interior liner.

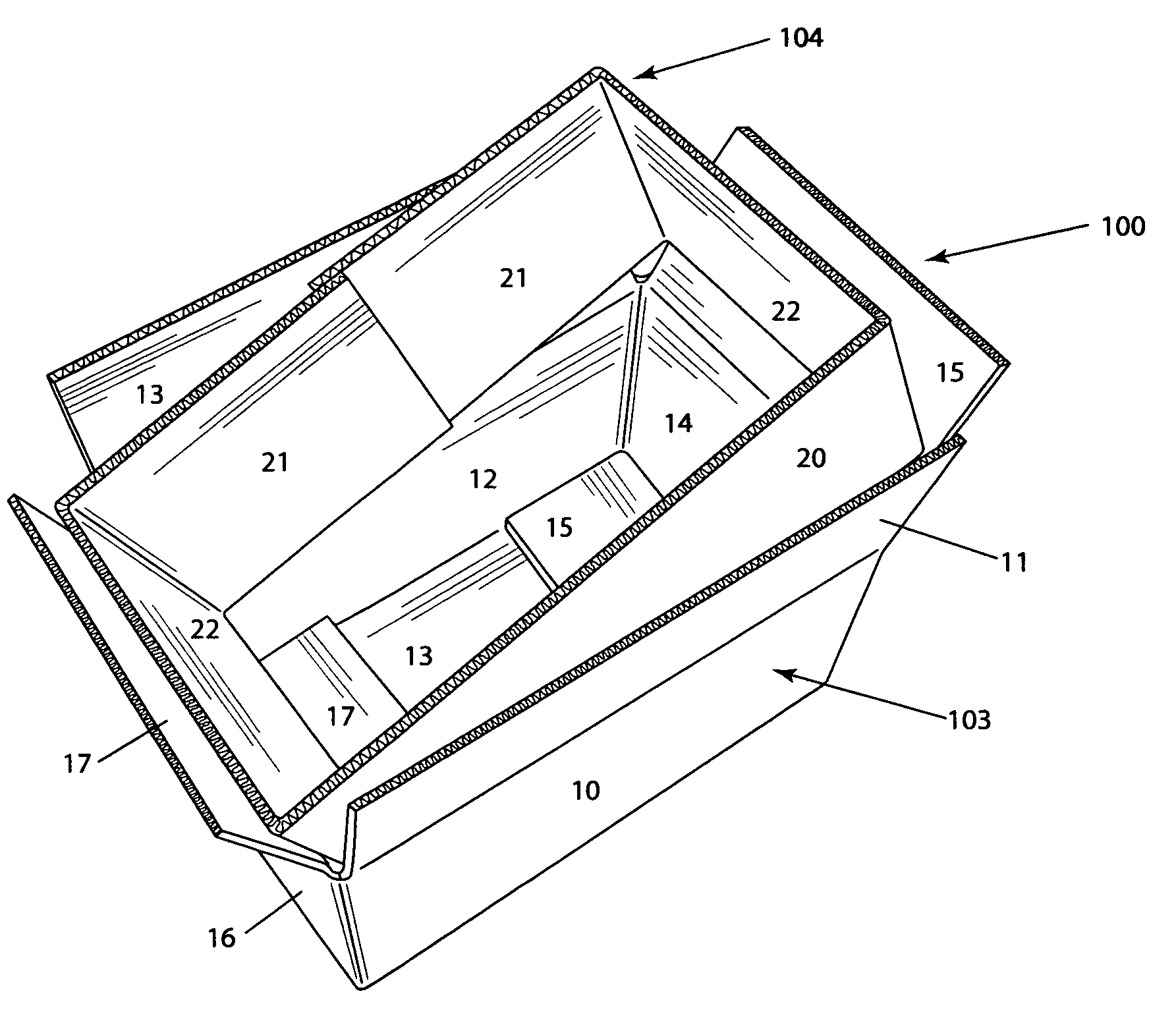

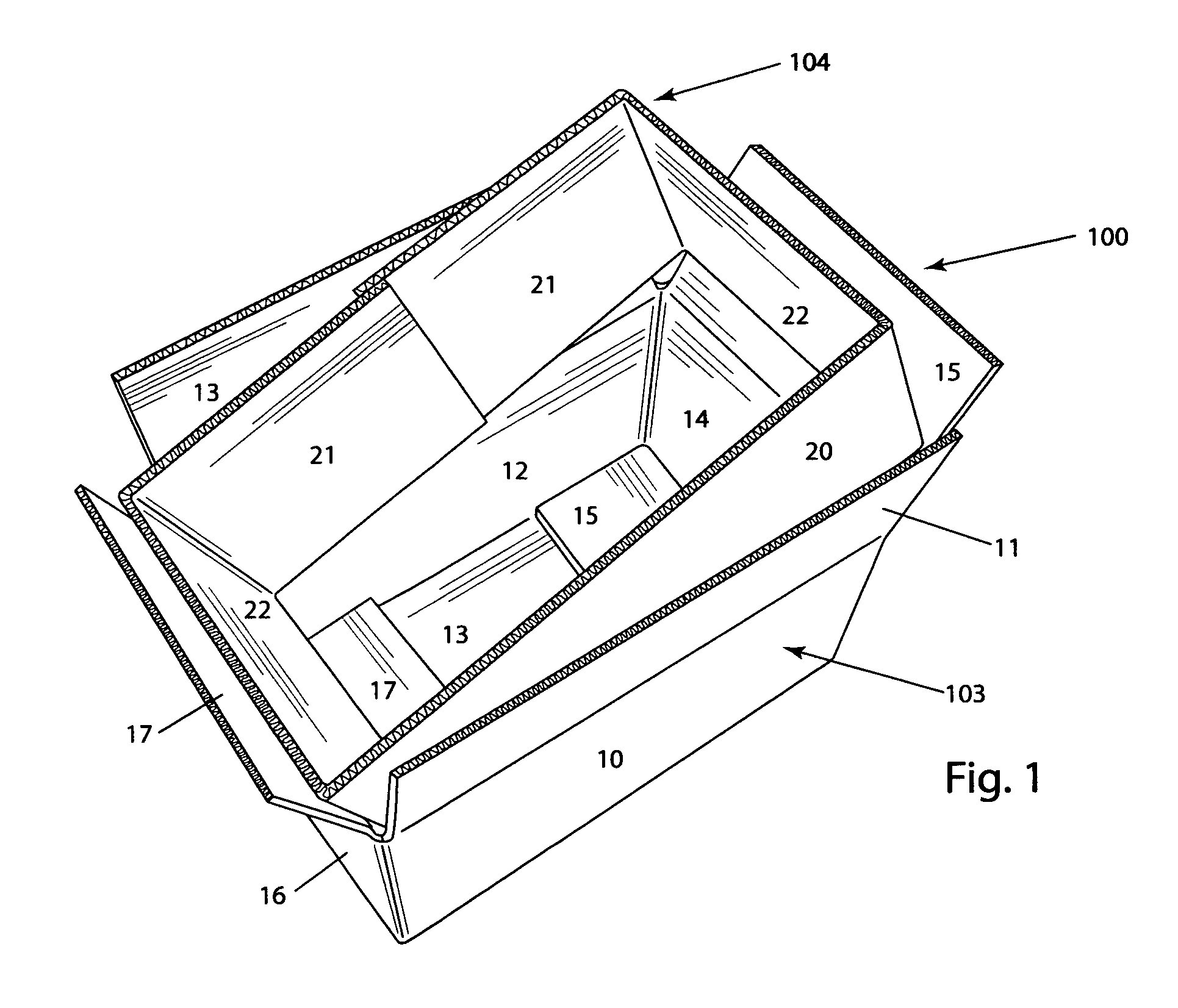

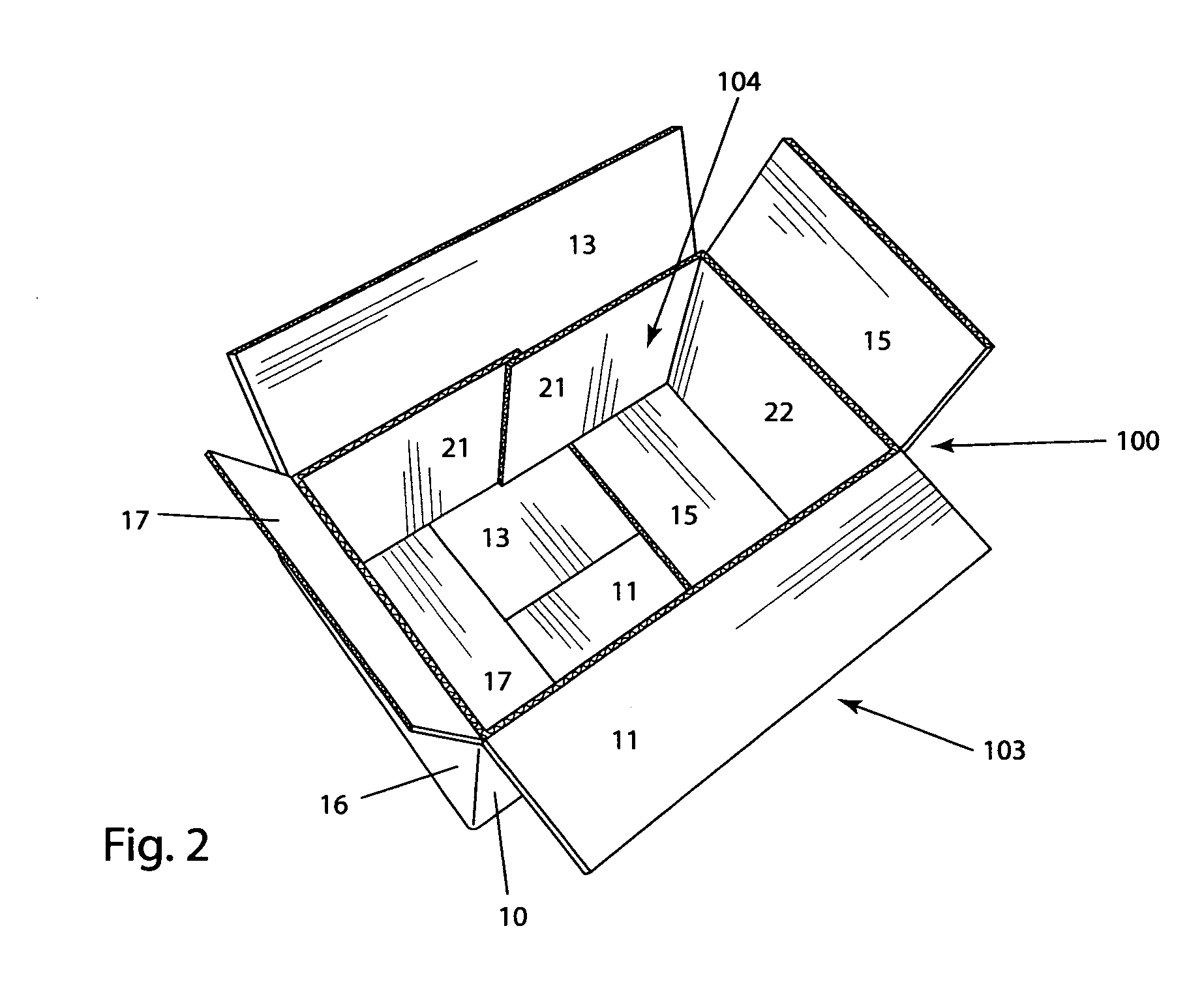

[0036]A first preferred embodiment is depicted in FIGS. 1, 2, 4-5, and 7 forming a regular slotted container (RSC) specifically sized to accommodate twelve assembled MRE™ rations. The two-piece container 100 of the present invention is assembled from the aforementioned corrugat...

second embodiment

[0040]In a second embodiment depicted in FIGS. 3, 6, and 8, a one-piece container 110 is depicted wherein a slotted container is formed with an integral divider sized to accommodate MRE™ rations. FIG. 3 shows the one-piece container 110 and divider of the present invention fully assembled with its divider in place.

[0041]As shown in FIG. 6, the one-piece container 110 of this embodiment is formed from the one-piece container die cutout 111 as shown. Thickened lines indicate score lines or creases created, for example, by embossing pressure or by a plurality of periodic incisions along the desired crease. The one-piece container die cutout 111 is generally approximately 69 inches in length and approximately 20 inches in width. Elements of the cutout 111 include a one-piece cutout first long sidewall 40 that is generally rectangular in shape and measures approximately 17 3 / 16 inches by approximately 9¼ inches. Adjacent each short dimension or end of this first sidewall 40 are identical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com