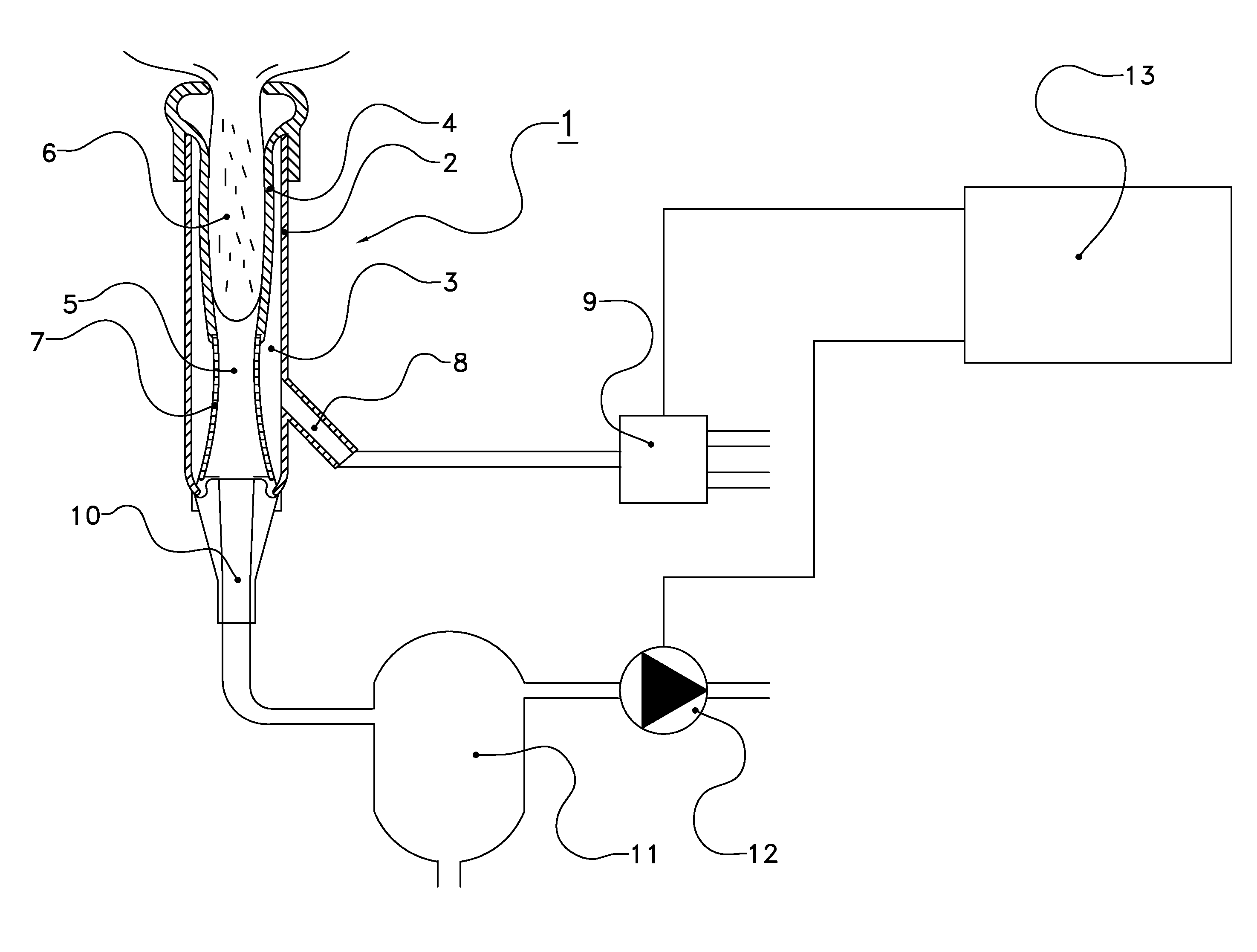

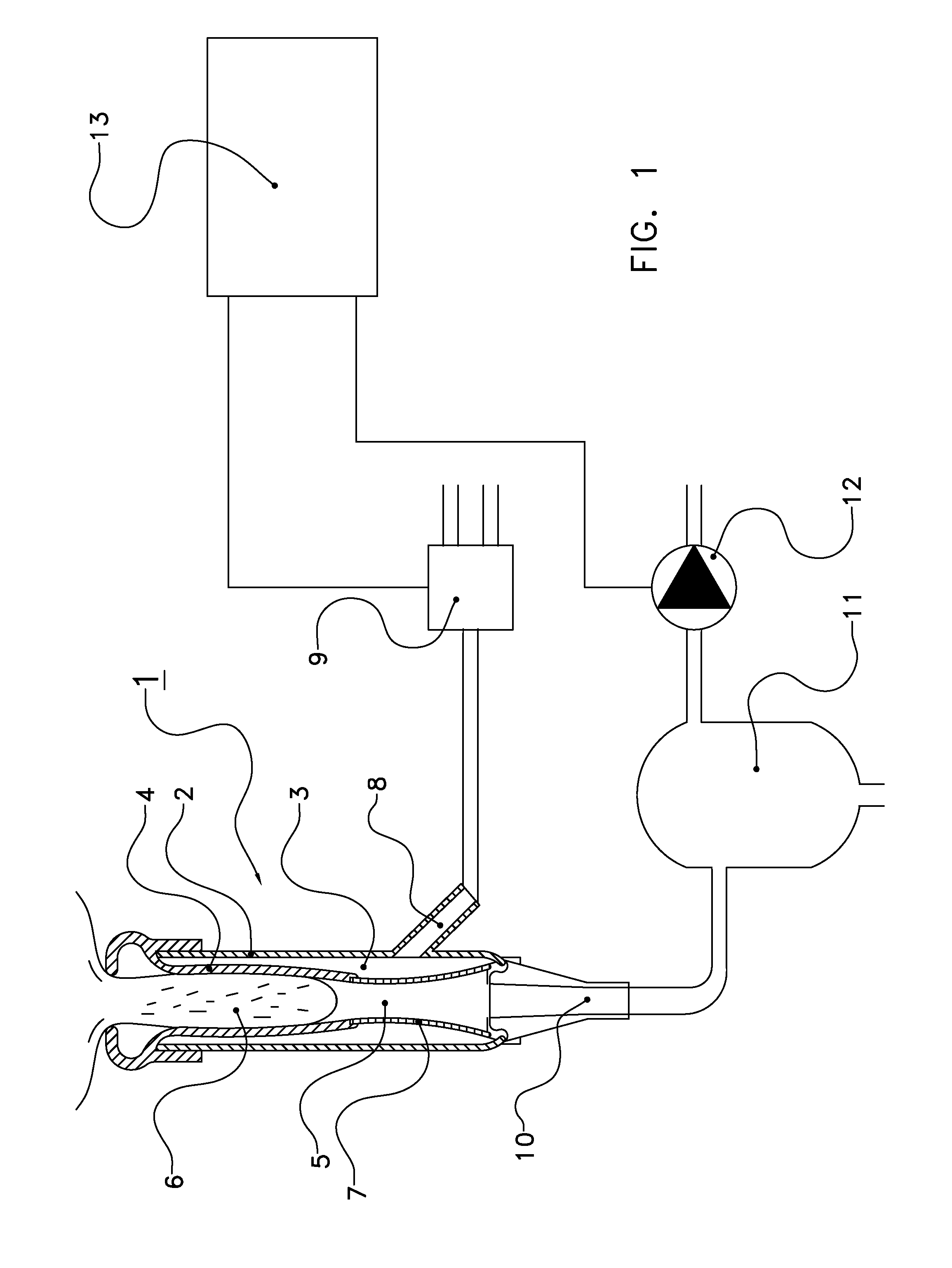

[0008]A great

advantage of the invention is that the milk line can be shut off at an earliest possible point, i.e. as far upstream as possible in the milk line, namely already in the cup liner itself. The chance of penetration of

dirt is thus further reduced with respect to a more downstream located shut-off valve. For, with the latter device, it is still possible for dirt to penetrate into the milk line, which dirt will then be sucked in further at a next milking action. Moreover, the device according to the present invention has a reduced number of components, because it does not comprise a separate valve, in contrast with the known device. This also results in a reduced chance of failures. As long as the pulsator and the cup liner will be able to pulsate for the milking action, these will normally also be able to shut off. For, this also takes place at the milking action itself, albeit in a pulsating manner and in each case only during a very short period of time.

[0009]One of ordinary skill in the art will appreciate that by the

phrase “shutting off the milk line in a stable, non-pulsating manner” what is meant that the milk line is shut off during a period of time of at least twice the longest closing duration during pulsation. In particular, the milk line is shut off during at least 10 seconds, and, more in particular, the period of time extends for as long as the milking vacuum pump provides a milking vacuum in the milk line. The device is thus well protected against sucking in

contamination.

[0010]In particular, the period of time also extends consecutive to a milking action, in particular in each case between two successive milking actions, such as substantially during the entire period of time between two milking actions. In this manner, the device is still better protected against

contamination, because it also remains closed when the vacuum pump is switched off, at least when no milking vacuum is provided in the milk line. In practice, the milking vacuum pump can be switched off when, for example, during a longer period of time no milking has been planned or is anticipated. Although, in that case, there is no chance of dirt being sucked in, dirt can still penetrate into the non-closed part of the milk line. The present invention is extra advantageous because said non-closed part is very short.

[0011]The milking device according to the invention is advantageously configured to cause the pulsator to provide an

overpressure in the pulsation space. By

overpressure is meant here an

overpressure with respect to

atmospheric pressure. This makes it possible to guarantee, of course at an overpressure that is sufficient to cause the cup liner to fold and close off, that the cup liner shuts off the milk line and keeps it closed, even if no milking vacuum is provided. On the other hand, if and as long as a milking vacuum is provided, the pressure that the pulsator should cause to prevail in the pulsation space may also be higher. In a particular situation, the milking vacuum pump is configured to continue to provide a milking vacuum in the milk line and the pulsator is configured to provide a pressure higher than

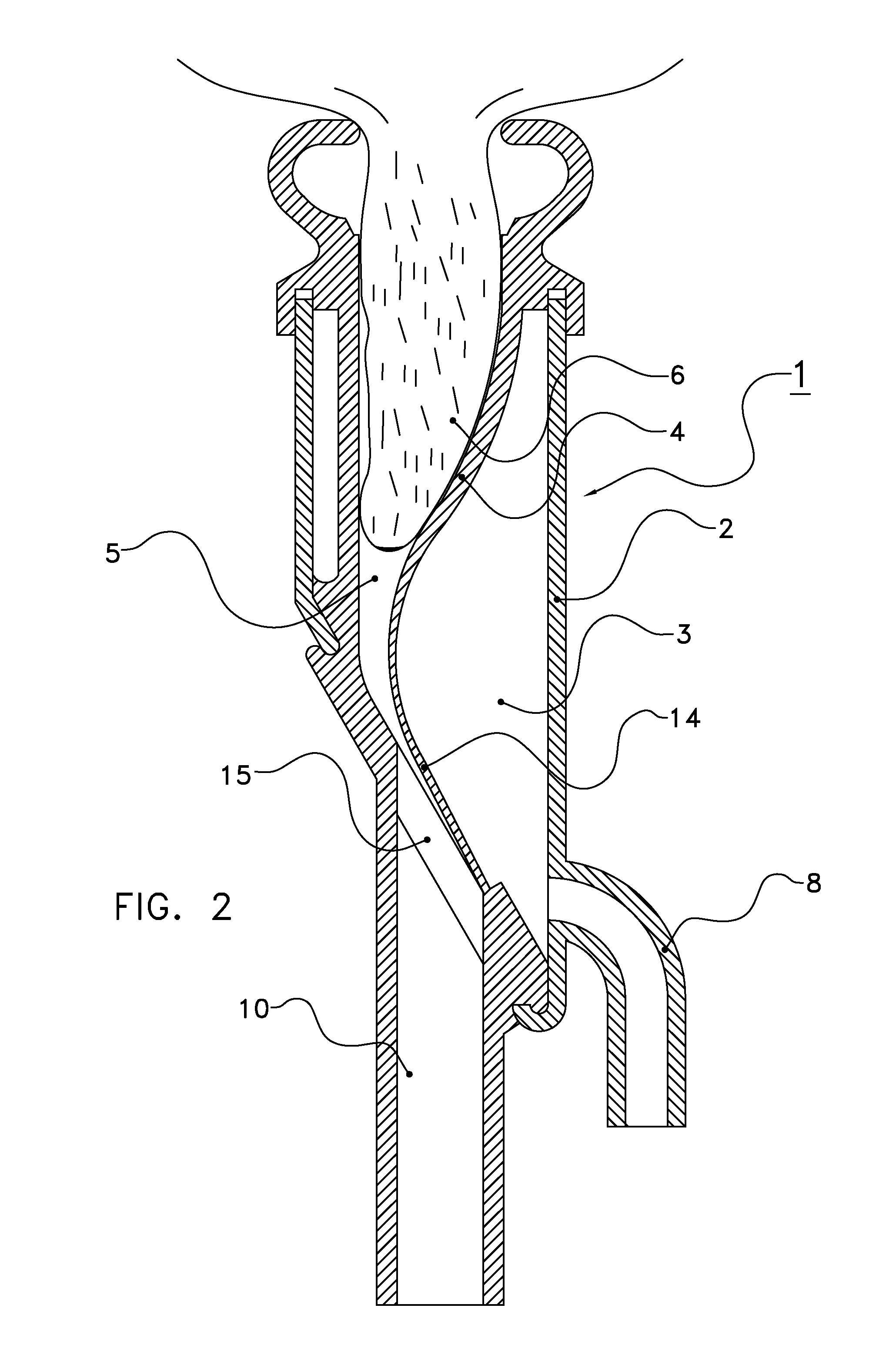

atmospheric pressure in the pulsation space, in such a manner that the

pressure difference is sufficient for shutting off the milk line in a stable and non-pulsating manner. At a milking vacuum of around 50 kPa, which is usual in practice, the cup liner will then close and remain closed. It is pointed out here that, with the usual cup liners, providing only

atmospheric pressure in the pulsation space has proved to be insufficient to keep the cup liner closed, even at a prevailing milking vacuum. In practice, when the pulsation space is only aerated, the cup liner will reopen after a short time by the own elasticity of the liner. This is caused by inwardly leaking air, usually a combination of unintentional leakage and leakage air currents through leakage openings which are provided for

milk flow stimulation, in which case the milking vacuum is insufficient to compensate therefor. In the present invention, the cup liner is nevertheless found to remain closed in this situation if a sufficiently great overpressure has been provided in the pulsation space.

[0012]The overpressure amounts in particular to at least 0.2 bar and at most 2 bar, more in particular to between 0.35 and 0.65 bar. At such pressures, the cup liner is found to shut off well, while in particular pressures between 0.35 and 0.65 can still be provided in a simple manner by customary pumping means which are also used for milking and / or pulsating vacuum. The pressures used therein are of the same

order of magnitude, in which case, if possible, only the pumping direction should be reversed.

[0013]In embodiments, the cup liner, in particular near the connection to the milk line, has a first wall portion with a folding resistance that is reduced with respect to other wall portions of the cup liner. In particular, the cup liner opposite to the first wall portion comprises a wall portion with a higher folding resistance, against which the first wall portion substantially shuts off the teat space at said

pressure difference. Such cup liners are pre-eminently suitable because they have already been prepared to shut off in a controlled and improved manner. They are marketed, for example, the AktivPuls liner

system by the company

System Happel GmbH, located in Miihlweg 4 / Salenwang D-87654 Friesenried, Germany. However, these known liners have in principle been developed for a better closing during a milking action, and the associated milking devices, equipped with such cup liners, are not designed according to the present invention.

Login to View More

Login to View More  Login to View More

Login to View More