Radial heat sink with heat pipe set therein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

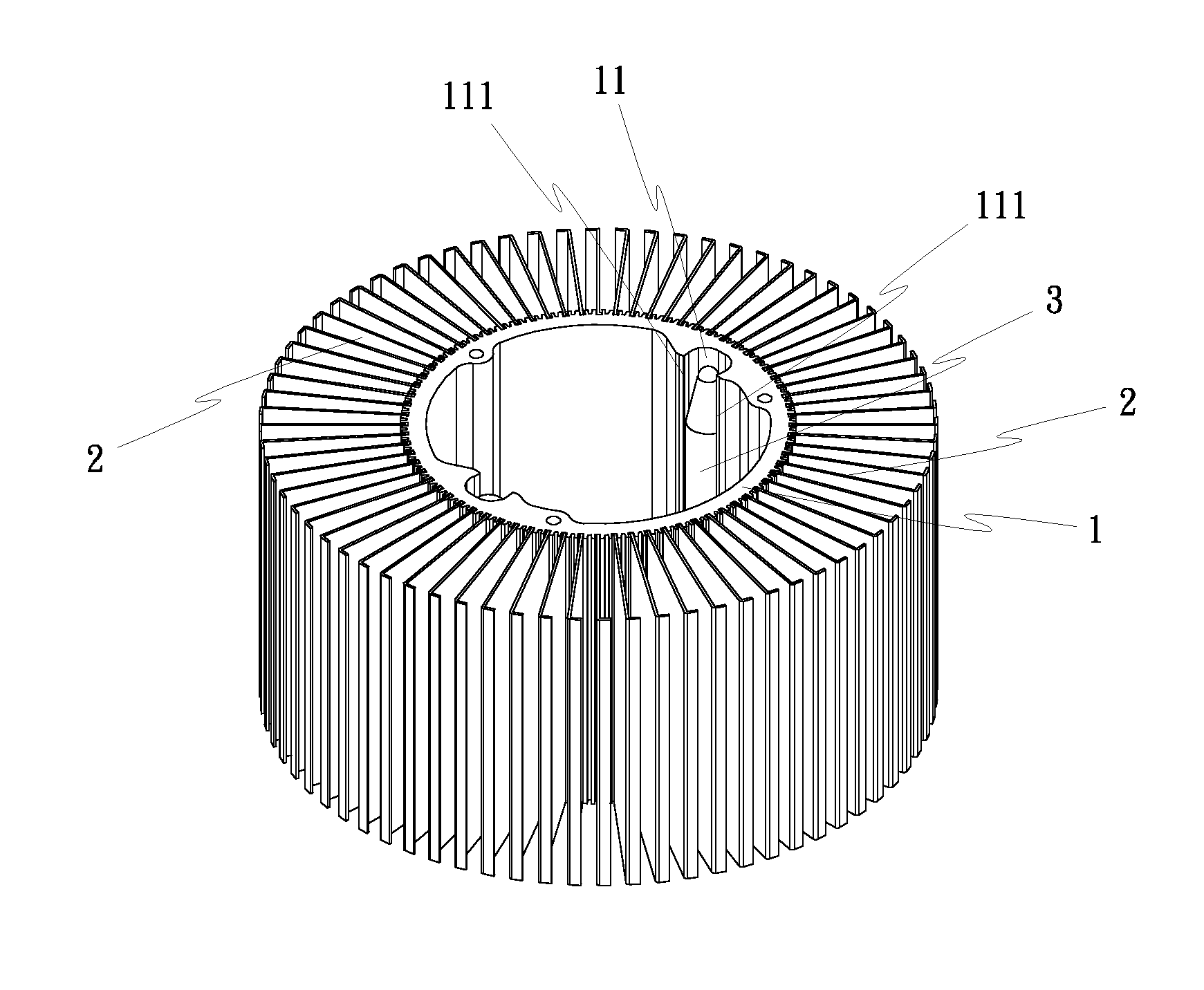

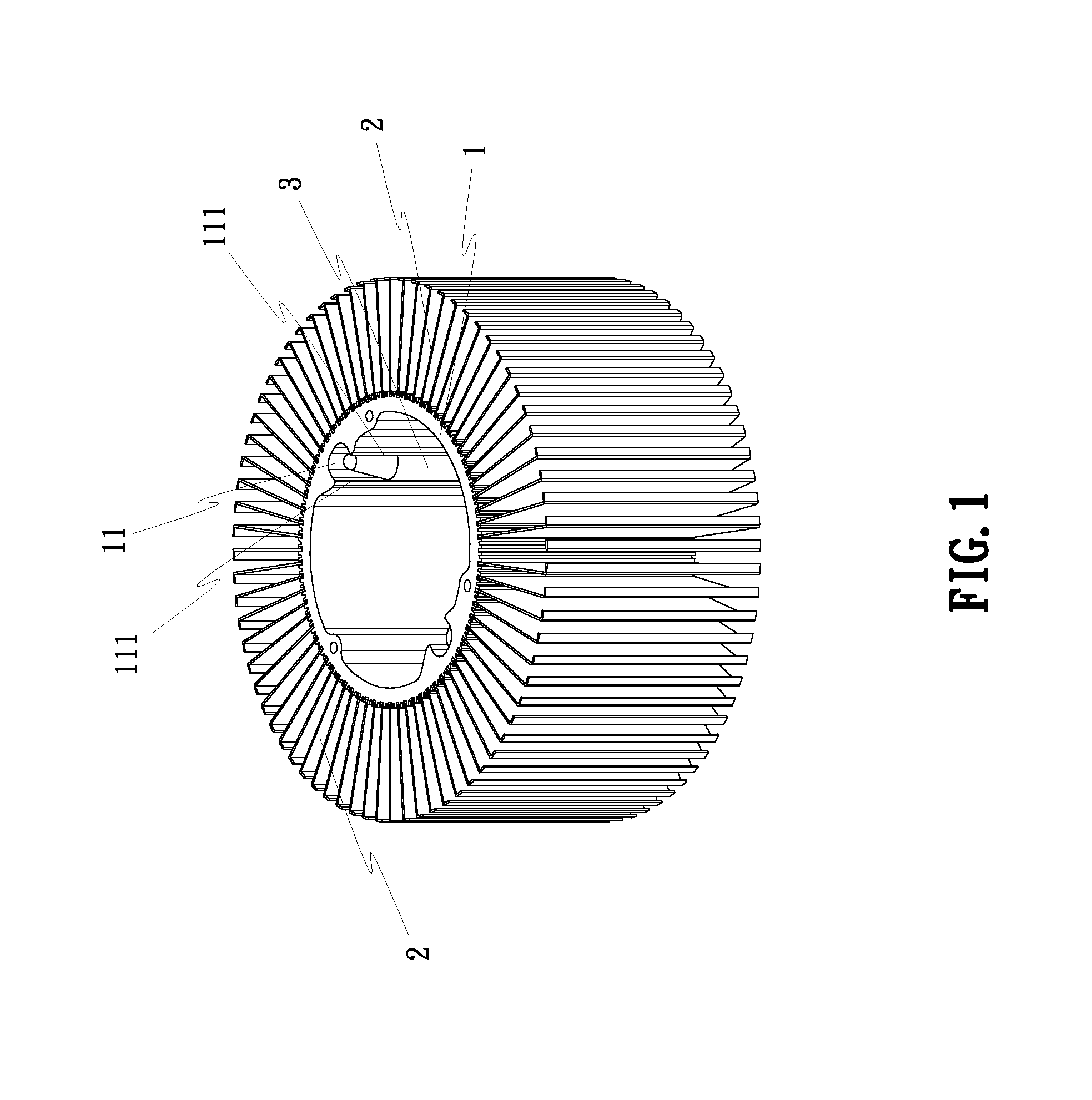

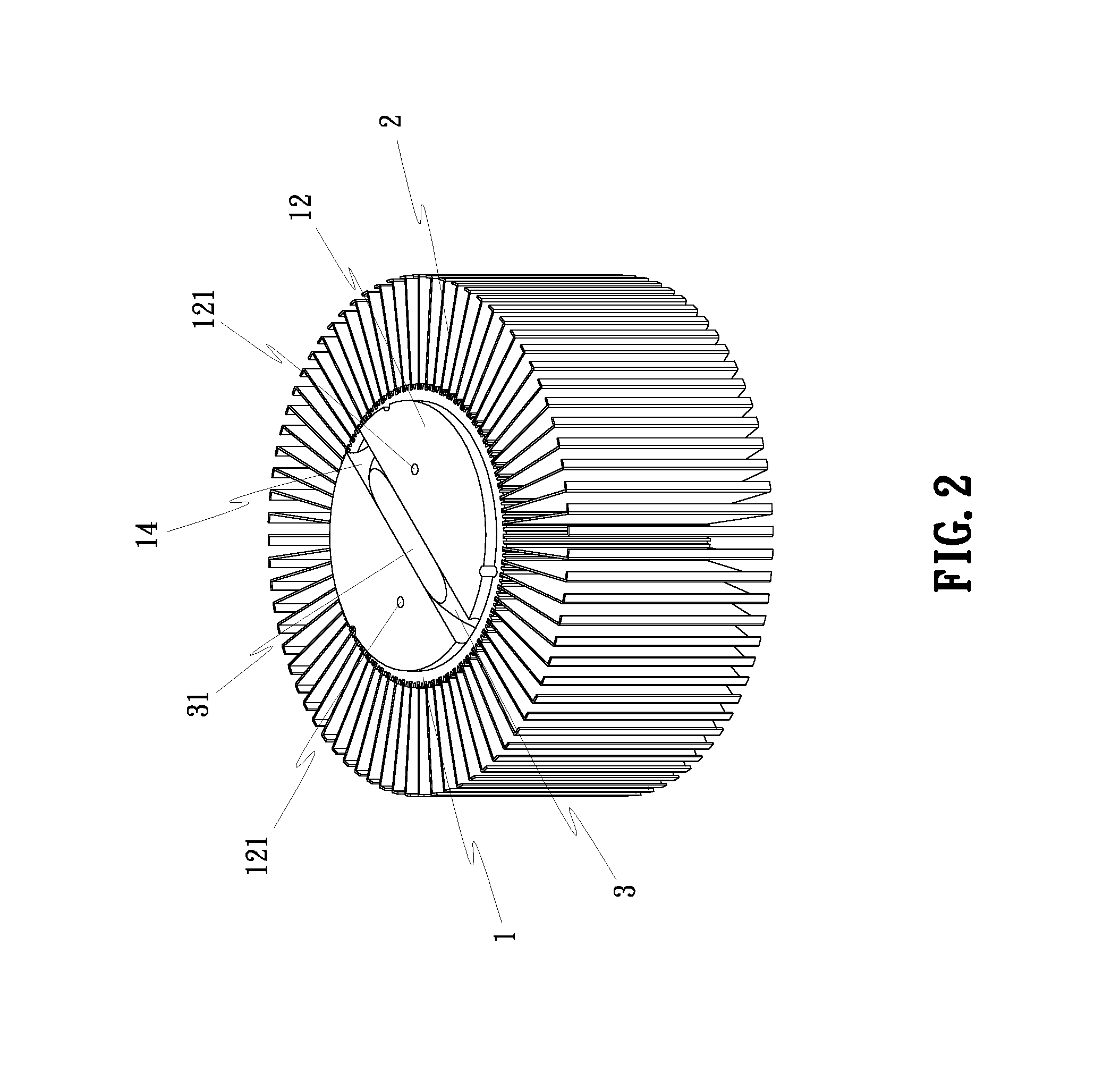

[0033]Referring to FIGS. 1-5, a radial heat sink in accordance with the present invention is shown comprising a core base 1, a plurality of radiation fins 2, and at least one, for example U-shaped, heat pipe 3.

[0034]The core base 1 is a tubular metallic member. The radiation fins 2 are equiangularly fastened to the periphery of the core base 1. The U-shaped heat pipe 3 is mounted inside the core base 1. The core base 1 has mounting grooves 11 located on the inside wall thereof for receiving the U-shaped heat pipe 3. When the two distal ends of the U-shaped heat pipe 3 are respectively press-fitted into one respective mounting groove 11 in the core base 1, the middle part 31 of the U-shaped heat pipe 3 is exposed to the outside of the core base 1 for direct contact with the heat-emitting device (CPU, LED lamp, or any other electronic component part that emits heat during its operation) for quick dissipation of waste heat from the heat-emitting device.

[0035]As shown in FIG. 6, the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com