Gas filling system and gas filling apparatus

a gas filling system and gas filling technology, applied in the field of gas filling systems, can solve the problems of increasing and reaching the inability to appropriately control the flow rate etc. of the coolant supplied to the cooling means, and the fear of making the driver wait, etc., to achieve suppressing the increase in the temperature of the gas tank, high accuracy, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

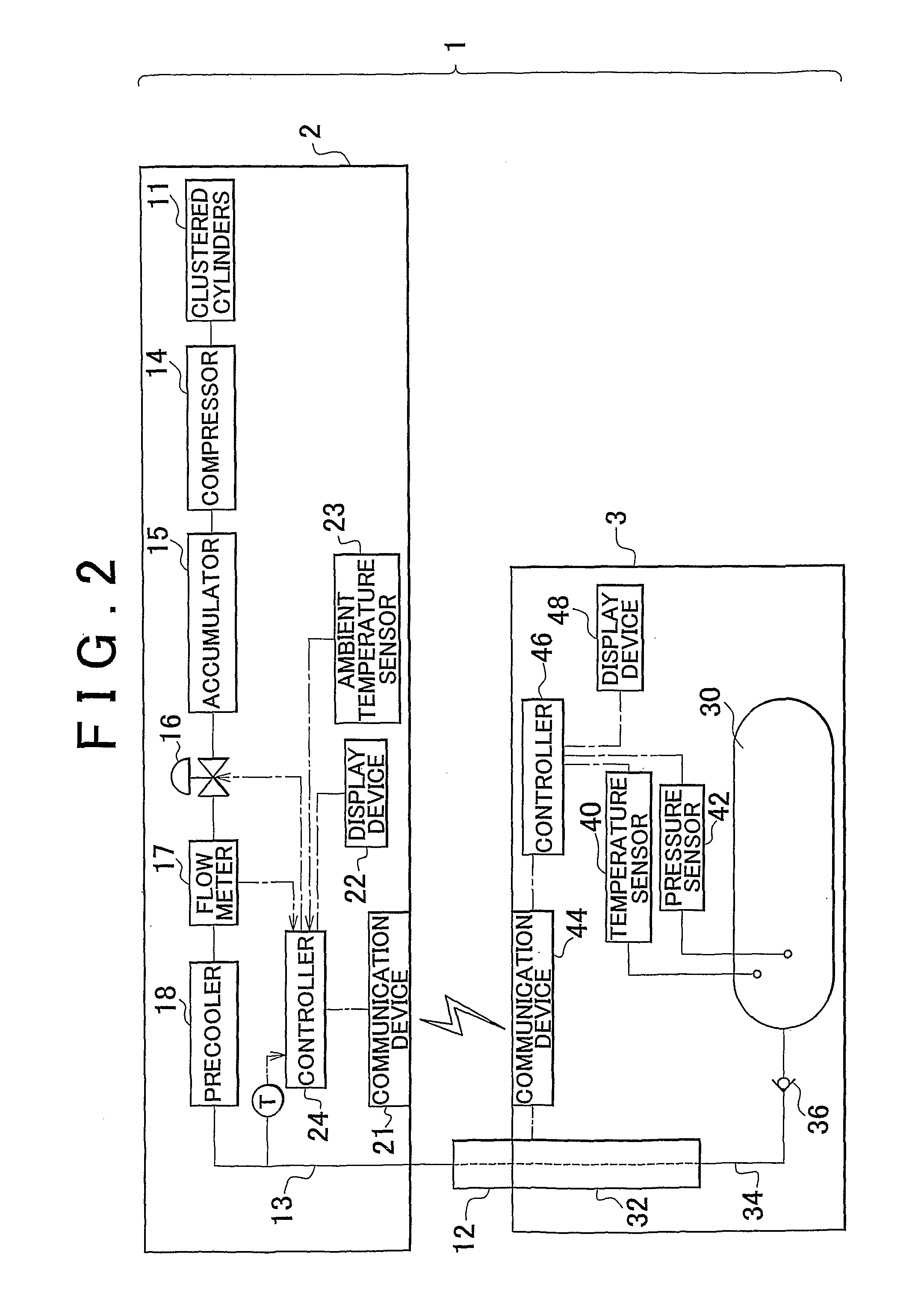

[0024]A gas filling system according to an example embodiment of the invention will be described below with reference to the attached drawings. An example of the gas filling system will be herein described, in which hydrogen gas is filled, via a gas filling apparatus, into a gas tank of a fuel cell vehicle equipped with a fuel cell system. As generally known, the fuel cell system includes a fuel cell that generates electricity through electrochemical reaction between fuel gas (hydrogen gas, for example) and oxidant gas (air, for example).

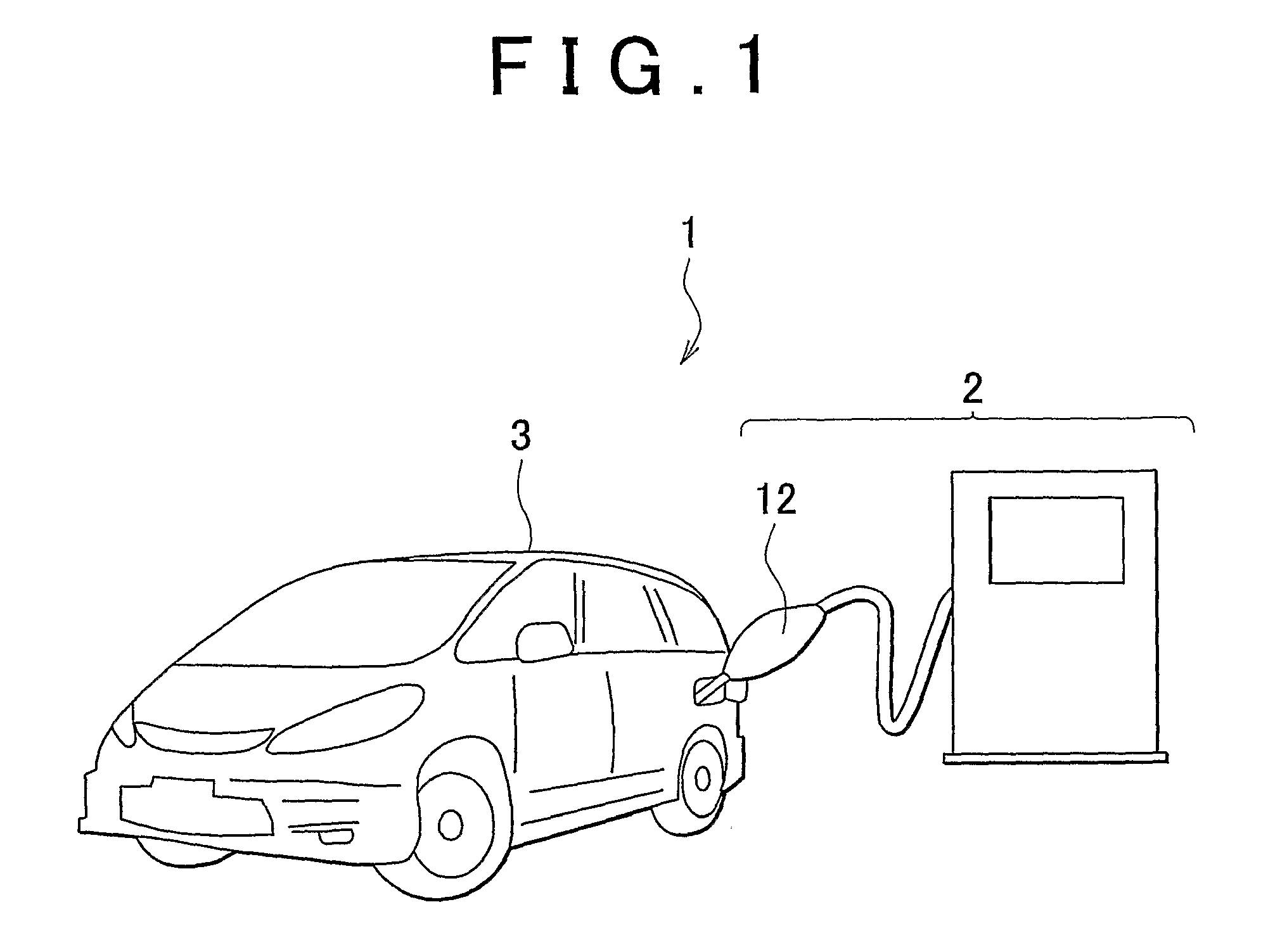

[0025]As shown in FIG. 1, the gas filling system 1 includes the gas filling apparatus 2 that is provided in a hydrogen station, for example, and a vehicle 3 supplied with the hydrogen gas from the gas filling apparatus 2.

[0026]As shown in FIG. 2, the gas filling apparatus 2 has clustered cylinders (gas supply source) 11 that store hydrogen gas, a filling nozzle 12 that discharges hydrogen gas into an on-board gas tank 30, and a gas line 13 that conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com