Method and system for servicing a wellbore

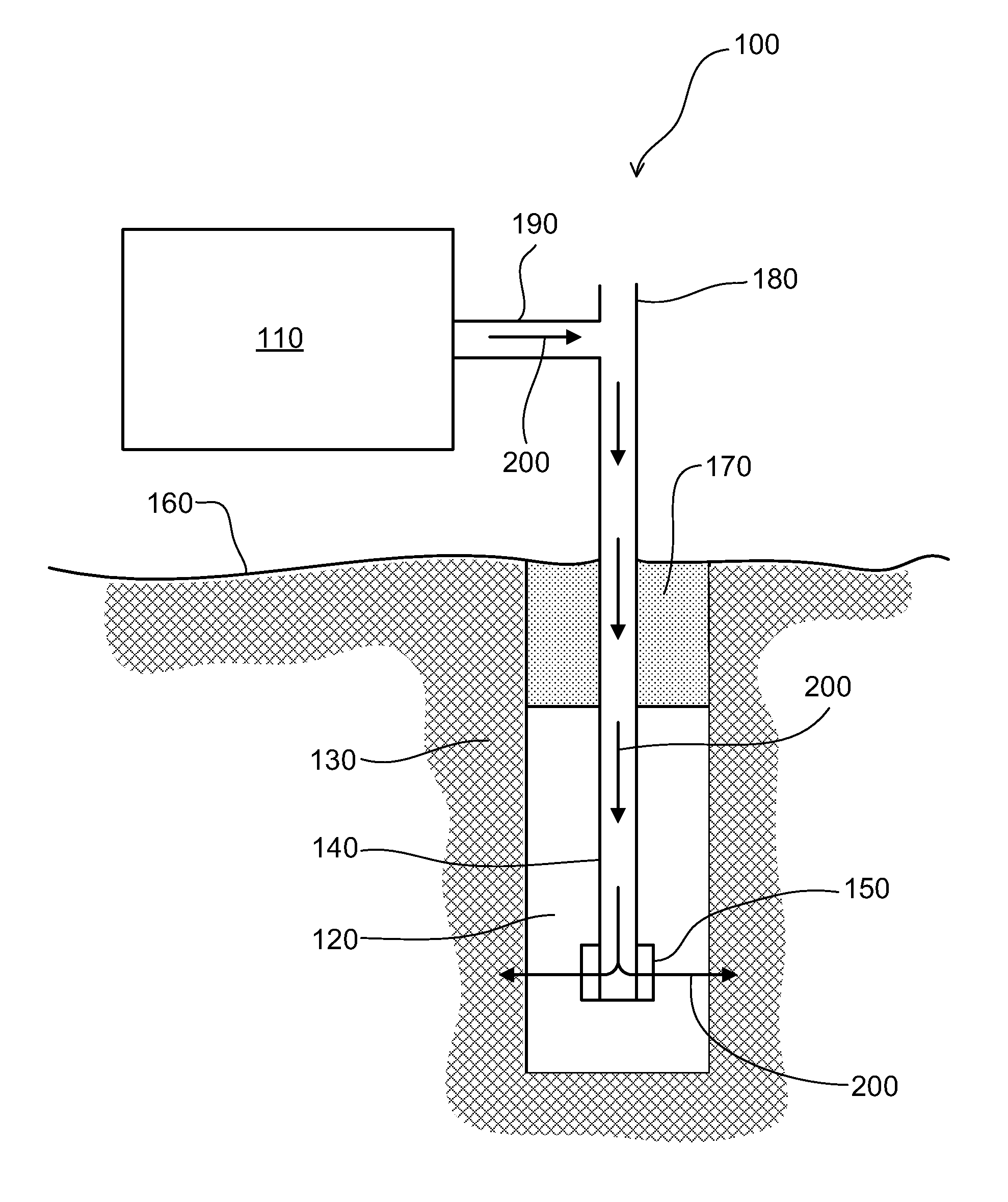

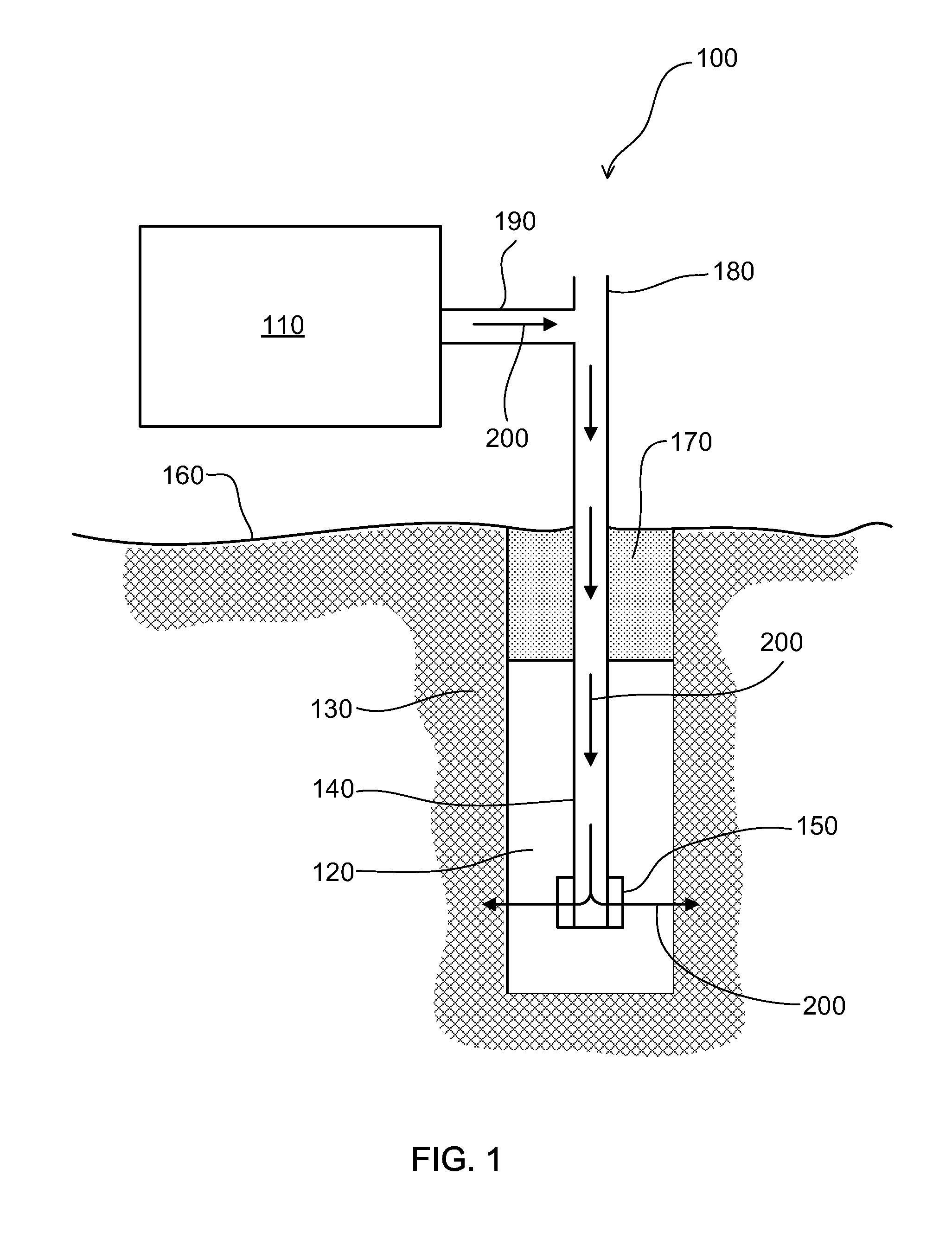

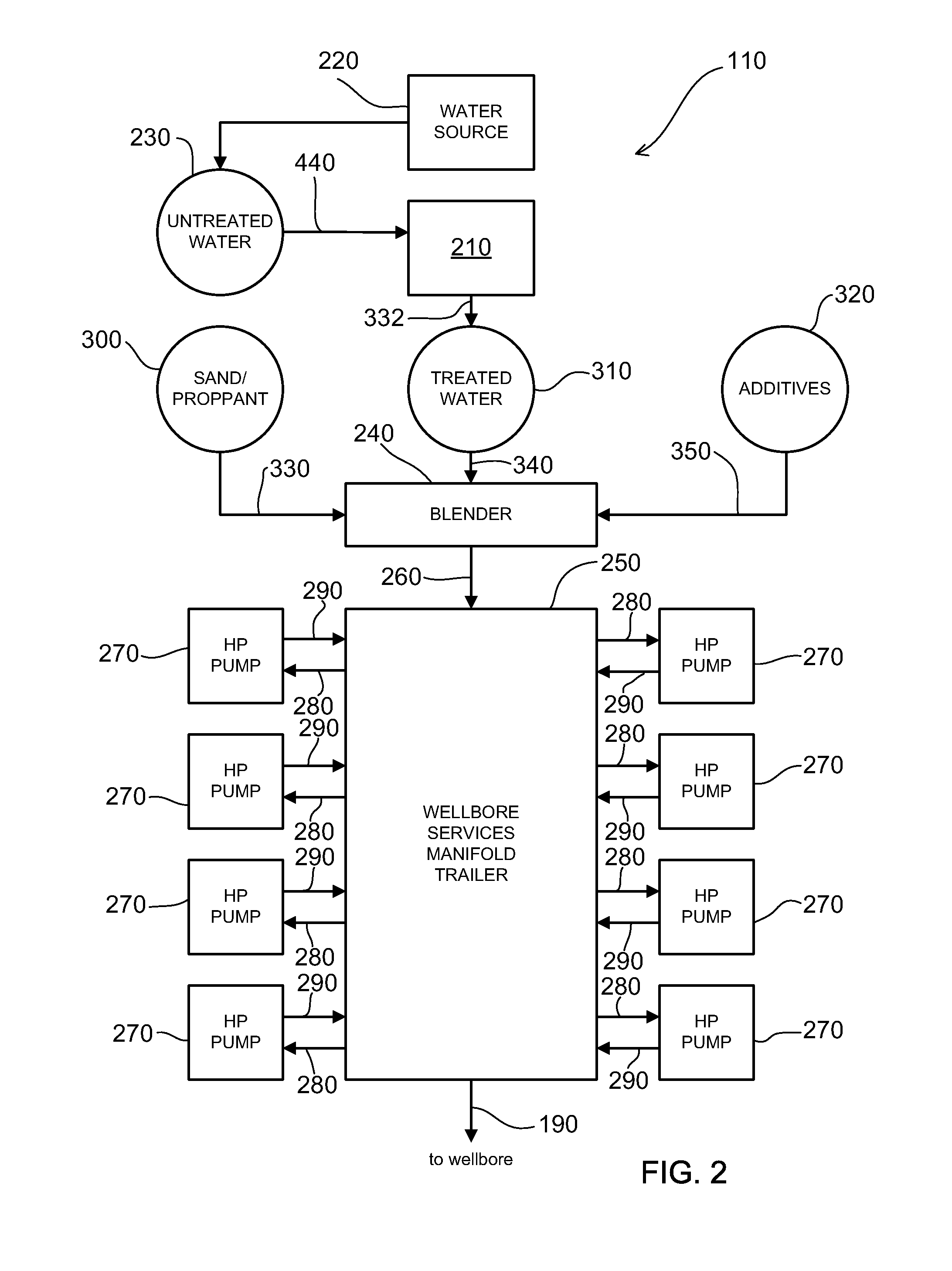

a wellbore and wellbore technology, applied in the field of water treatment, can solve the problems of inability to use wellbore water, inability to extract water from a wellbore, and inability to provide fluid supply local to a wellbore,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment a

[0057]A method of servicing a wellbore, comprising:

[0058]transporting a plurality of wellbore servicing equipment to a well site associated with the wellbore;

[0059]accessing a water source to form a water stream from the water source to at least one of the plurality of wellbore servicing equipment;

[0060]passing a direct electrical current through the water stream obtained from the water source to coalesce an undissolved solid phase and an undissolved organic phase in the water stream;

[0061]separating the coalesced undissolved solid phase and the coalesced undissolved organic phase from the water stream to yield a substantially single-phase water stream;

[0062]adding ozone to the substantially single-phase water stream to yield an ozonated water stream;

[0063]irradiating the ozonated water stream with ultraviolet light to yield an irradiated water stream;

[0064]forming a wellbore servicing fluid using the irradiated water stream; and

placing the wellbore servicing fluid into the wellbore...

embodiment b

[0065]The method of embodiment A, further comprising adding additional ozone to the irradiated water stream prior to forming the wellbore servicing fluid.

embodiment c

[0066]The method of any preceding embodiment, wherein the water stream obtained from the water source has a turbidity >50 NTU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com