Backlight lamp cover, backlight backboard and liquid crystal display module

a liquid crystal display module and backlight technology, applied in non-linear optics, instruments, optics, etc., can solve the problems of low efficiency of assembling the backlight, large proportion of the cost of the entire liquid crystal display, and low development cost of dies, so as to improve the structure of the lamp cover and dissipate heat. , the effect of improving the structure of the backboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

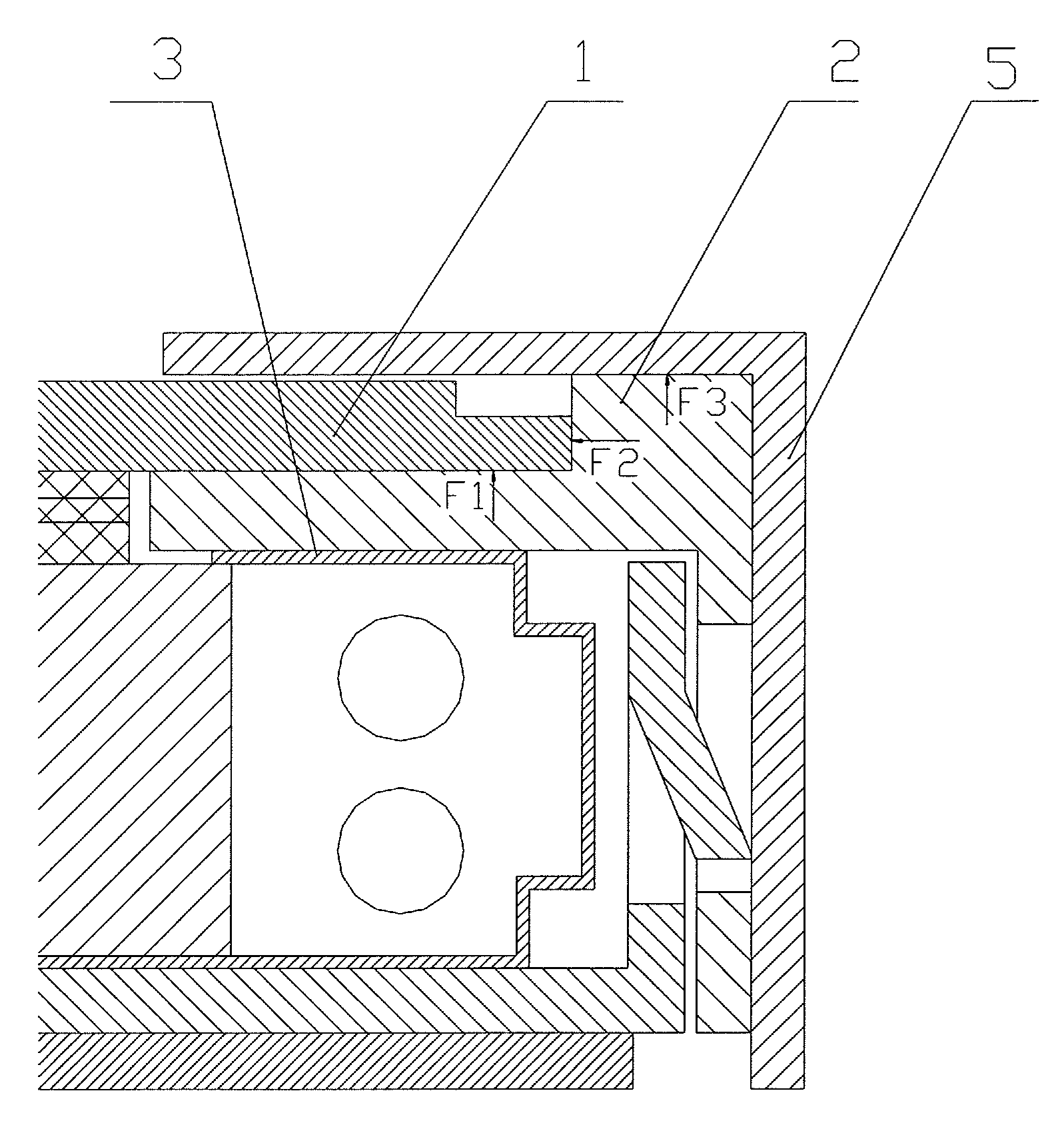

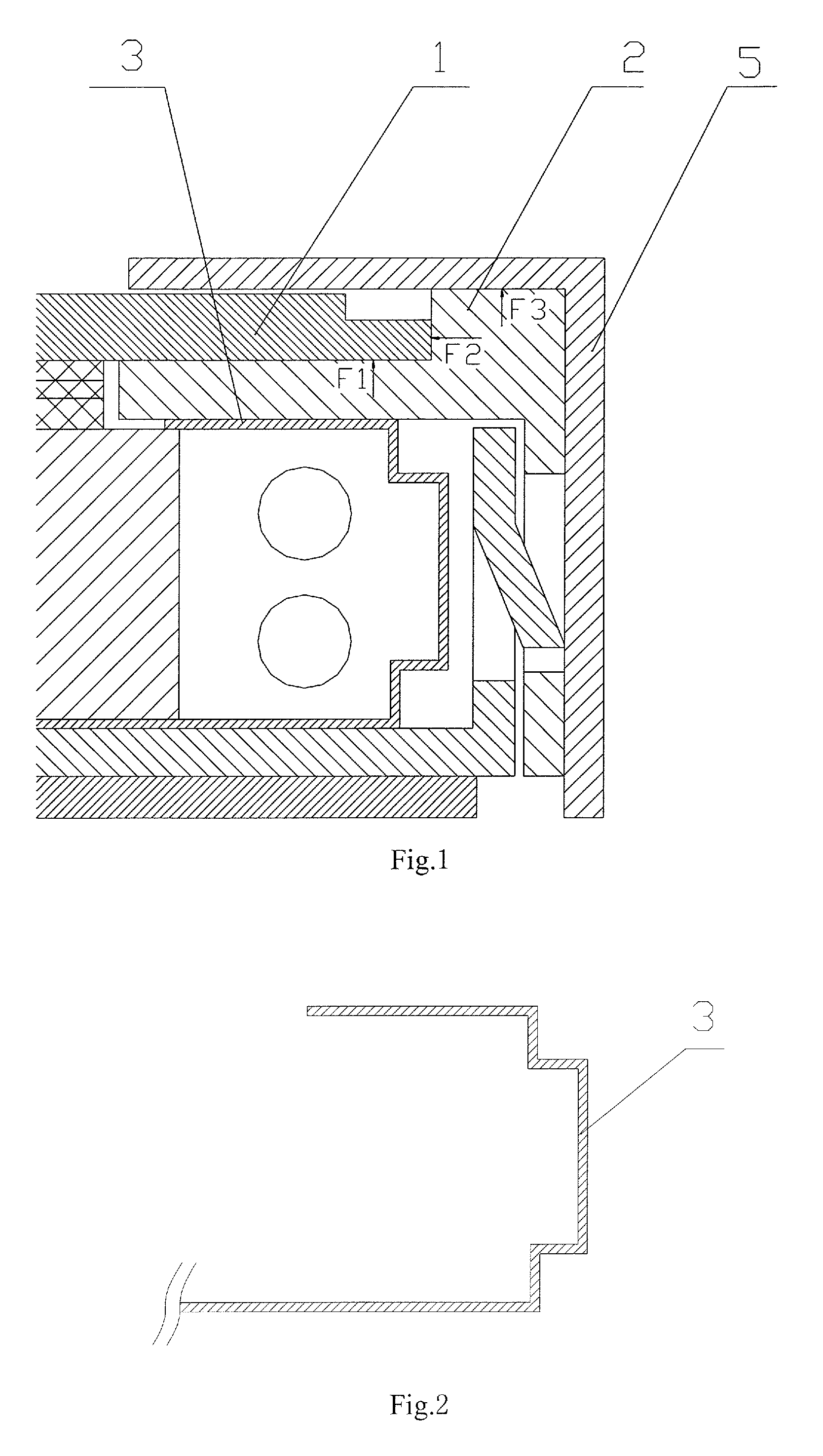

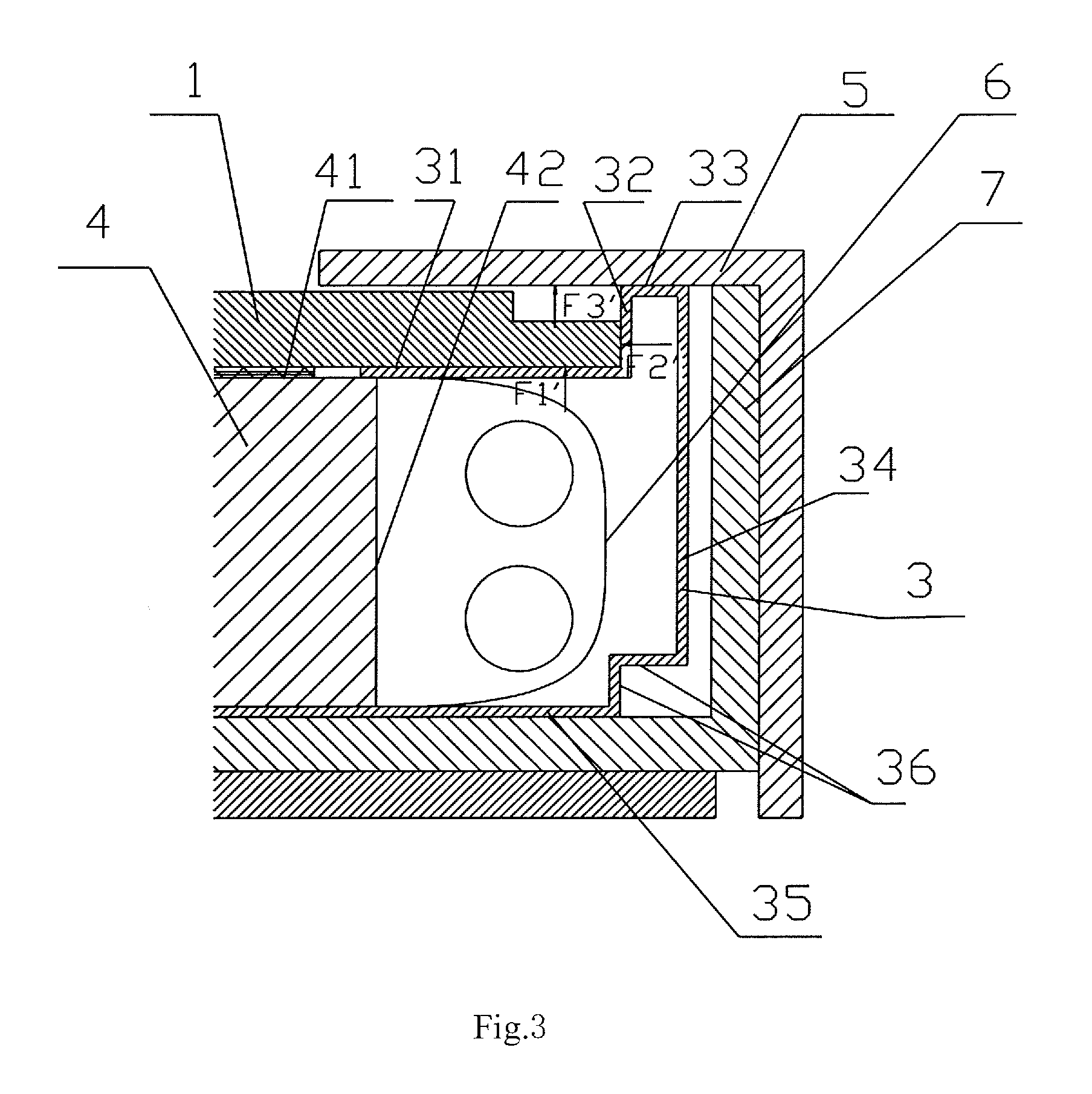

[0021]This embodiment provides a backlight lamp cover. As shown in FIG. 3 and FIG. 4, besides the functions of protecting a lamp tube and dissipating heat from the lamp tube, the backlight lamp cover 3 further comprises a supporting plate 31, which is mounted at a light emitting surface side of a light guide plate 4 and directly supports a liquid crystal display panel 1, with the supporting force for supporting the liquid crystal display panel illustrated as F1′ in FIG. 3. Moreover, a bending structure is added on an edge of the supporting plate 31. A first turning portion 32 of the bending structure is bent upward in FIG. 3 so as to limit a movement of the liquid crystal display panel 2 on the supporting plate 31 by means of the first turning portion 32. The acting force of the first turning portion 32 for limiting the movement of the liquid crystal display panel 1 is illustrated as F2′ in FIG. 3. The bending structure also comprises a second turning portion 33 ...

second embodiment

The Second Embodiment

[0026]The present embodiment provides a backlight backboard. As shown in FIG. 3 and FIG. 7, the backboard 7 is used for mounting a backlight lamp cover 3. However, the backlight lamp cover 3 is only accommodated at the side portion of the backlight backboard 7 corresponding to the light incident surface of the light guide plate 4, whereas the side portions of the backlight backboard 7 not accommodating the backlight lamp cover 3 do not completely limit the position of the liquid crystal display panel 1 In consideration of the above situation, the structure of the backlight backboard 7 is also improved correspondingly, so that the backlight backboard 7 comprises a stepped structure located at the top end of a side portion thereof not accommodating the backlight lamp cover 3. The stepped structure comprises a supporting portion 71 for supporting the liquid crystal display panel 1 and a stopper portion 72 for limiting a movement of the liquid crystal display panel ...

third embodiment

The Third Embodiment

[0029]The present embodiment provides a liquid crystal display module, which, as shown in FIG. 3 and FIG. 7, comprises a light guide plate 4, a liquid crystal display panel 1 and a bezel 5. The module further comprises: a backlight lamp cover 3, which comprises a supporting plate 31 located at a light emitting surface side of a light guide plate for supporting the liquid crystal display panel 1 and having at an edge thereof a bending structure that comprises a first turning portion 32 for limiting a movement of the liquid crystal display panel on the supporting plate 31 and a second turning portion 33 for supporting the bezel 5; and a backlight backboard 7, of which the side portion corresponding to the light incident surface of the light guide plate 4 is used for accommodating the backlight lamp cover 3, and the side portions not accommodating the backlight lamp cover 3 are provided at the top end thereof with a stepped structure that comprises a supporting port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com