Controlling the stiffness of a hollow metal bat by providing helical internal ribs

a hollow metal bat and internal rib technology, applied in the field of metal baseball bats and softball bats, can solve the problems of large cast grains, brittleness, and easy fracture of cast grains, and achieve the effects of reducing hoop frequency, improving bat performance, and controlling bat stiffness

Inactive Publication Date: 2012-09-13

ATI PROPERTIES

View PDF11 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

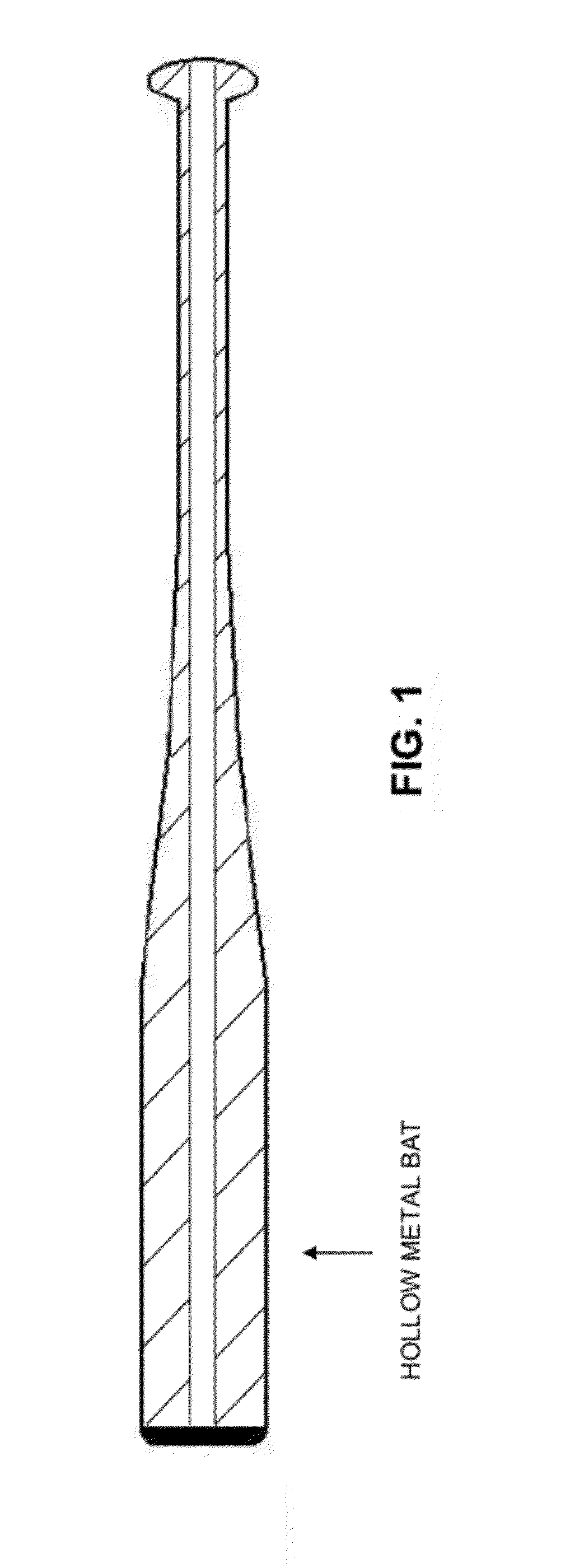

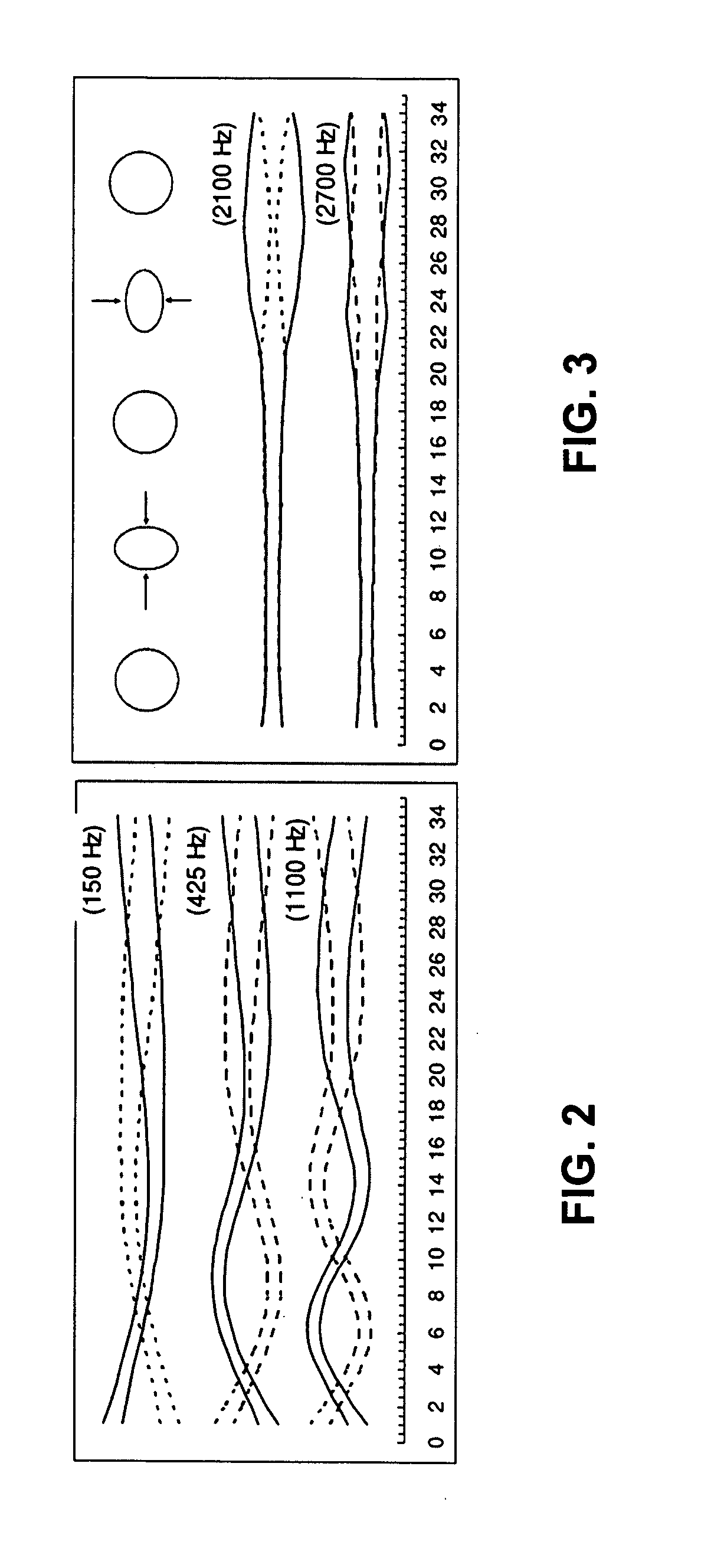

[0007]In accordance with the present invention, one or more helical internal ribs are formed on the interior of the hollow metal bat in order to control the stiffness of the bat and thereby lower hoop frequencies (and hence improve bat performance). The helical internal ribs also help to minimize bending failure modes and hoop failure modes. The one or more helical internal ribs may vary in frequency (i.e., number), pitch, height and width profile in order to provide the bat with the desired performance characteristics. Among other things, the goal of the invention is to coordinate the frequency (i.e., number) of the spiral ribs disposed about the inner circumference of the bat barrel, and the pitch, height and width profile of those ribs, so as to allow the creation of a thin wall, light weight bat barrel, while tuning (i.e., controlling) the stiffness of the barrel. Controlling the stiffness of the barrel consequently controls the “trampoline effect” of the barrel, whereby to ensure maximum bat performance while staying within bat regulations. Without helical internal ribs, the only other way to control the stiffness of the bat is to either (i) increase the thickness of the side wall of the bat (which is undesirable since it increases the weight of the bat), and / or (ii) form the bat out of a material which has a higher modulus of elasticity (which typically means using a denser, and hence heavier, material).

[0009]U.S. Pat. No. 2,340,156 relates to “cast integral” longitudinal ribs. These longitudinal ribs have little effect on the hoop modes of the bat. In contrast, the helical internal ribs of the present invention improve both the hoop modes and the bending modes of the hollow metal bat. Furthermore, the “cast integral” casting of U.S. Pat. No. 2,340,156 is done hot, yielding cast grains which are large, often brittle and susceptible to fracture—all features which are undesirable in a bat. In contrast, the cold worked helical internal ribs of the present invention provide both dimensionally—and metallurgically—superior ribs.

Problems solved by technology

Without helical internal ribs, the only other way to control the stiffness of the bat is to either (i) increase the thickness of the side wall of the bat (which is undesirable since it increases the weight of the bat), and / or (ii) form the bat out of a material which has a higher modulus of elasticity (which typically means using a denser, and hence heavier, material).

Furthermore, the “cast integral” casting of U.S. Pat. No. 2,340,156 is done hot, yielding cast grains which are large, often brittle and susceptible to fracture—all features which are undesirable in a bat.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0106]By way of example but not limitation, in one preferred form of the invention, hollow metal bat 5 may be formed out of aluminum, may have a barrel wall thickness of 0.092″, and may have a single helical internal rib 40 having a pitch of one revolution over 12″ and a rib height of 0.050″ (off the floor of the barrel wall).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

A hollow metal bat comprising an elongated tubular structure having a barrel portion, a handle portion and a tapered portion connecting the barrel portion to the handle portion, and further comprising at least one helical internal rib formed along at least a portion of the elongated tubular structure.

Description

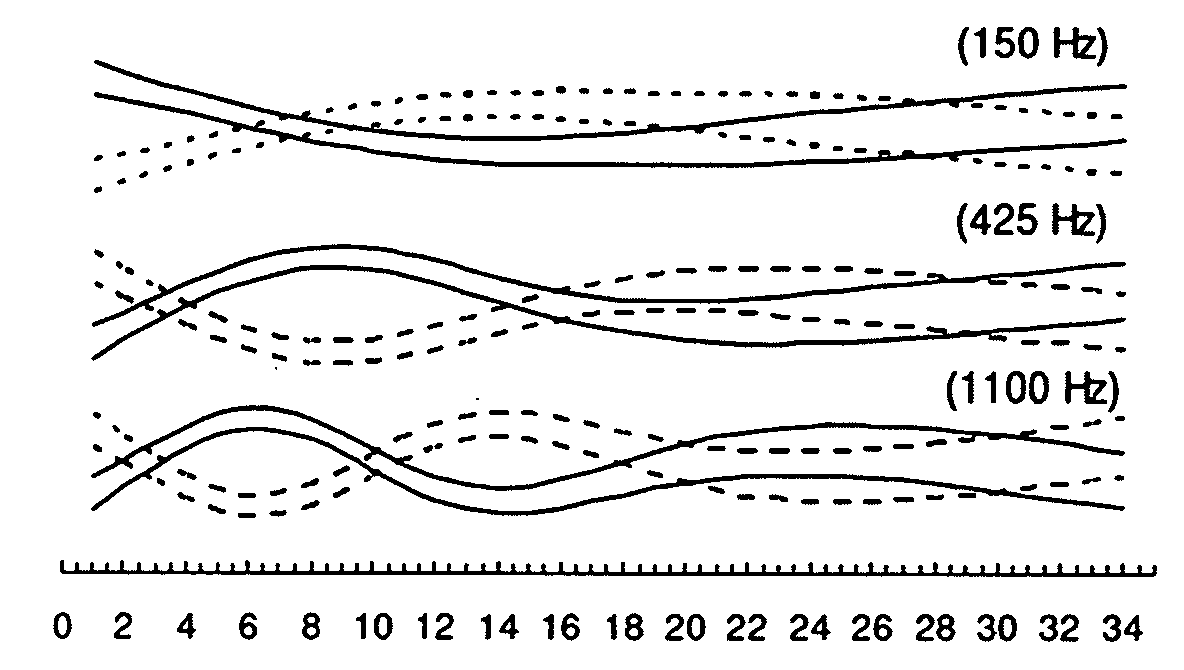

REFERENCE TO PENDING PRIOR PATENT APPLICATION[0001]This patent application claims benefit of pending prior U.S. Provisional Patent Application Ser. No. 61 / 448,063, filed Mar. 1, 2011 by Matthew Fonte for CONTROLLING THE STIFFNESS OF A METAL BAT BY CREATING INTERNAL RIBS (Attorney's Docket No. FONTE-5 PROV), which patent application is hereby incorporated herein by reference.FIELD OF THE INVENTION[0002]This invention relates to baseball bats and softball bats in general, and more particularly to metal baseball bats and metal softball bats.BACKGROUND OF THE INVENTION[0003]Baseball bats and softball bats (hereinafter sometimes referred to simply as “bats”) are well known in the art. Originally, bats were made of wood. However, more recently, some bats (and particularly softball bats) have been made of metal. In general, metal bats are made with a hollow construction in order to reduce their weight. See FIG. 1, which shows an exemplary hollow metal bat.[0004]Metal bats exhibit two types...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): A63B59/06B21D9/04

CPCB21D22/16A63B59/0092A63B59/0077A63B59/06A63B59/50A63B59/51A63B60/00A63B60/48A63B60/54A63B2102/18

Inventor FONTE, MATTHEW

Owner ATI PROPERTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com