Manufacturing method of foldable artificial vitreous body and mould thereof

a technology of artificial vitreous body and mould, which is applied in the field of foldable capsular vitreous body, can solve the problems of difficult removal, easy to remain in the eyes with perfluorocarbon liquid, and inability to generate sustained top-pressure on the retina, etc., and achieves advanced and stable technology, high biocompatibility, and excellent flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

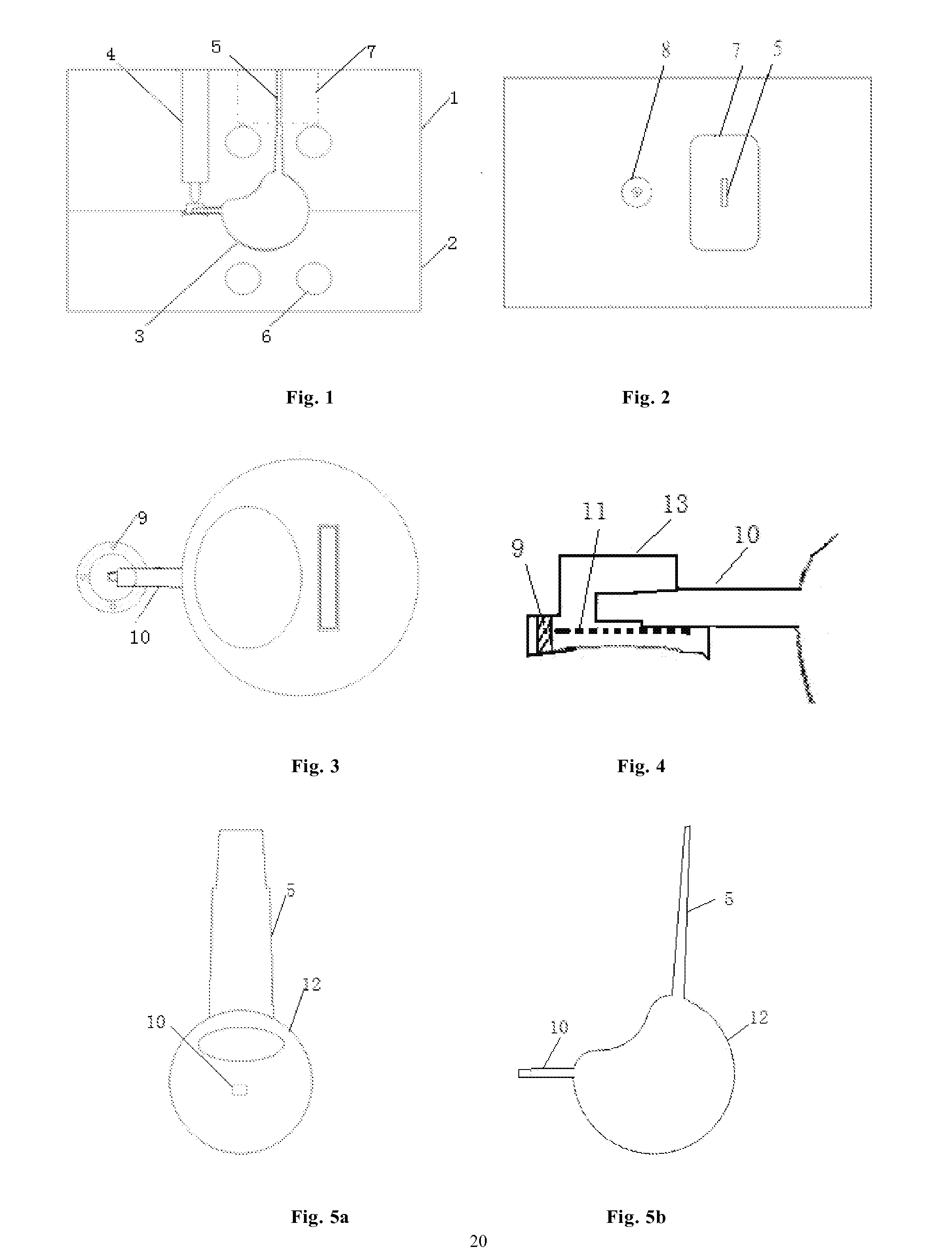

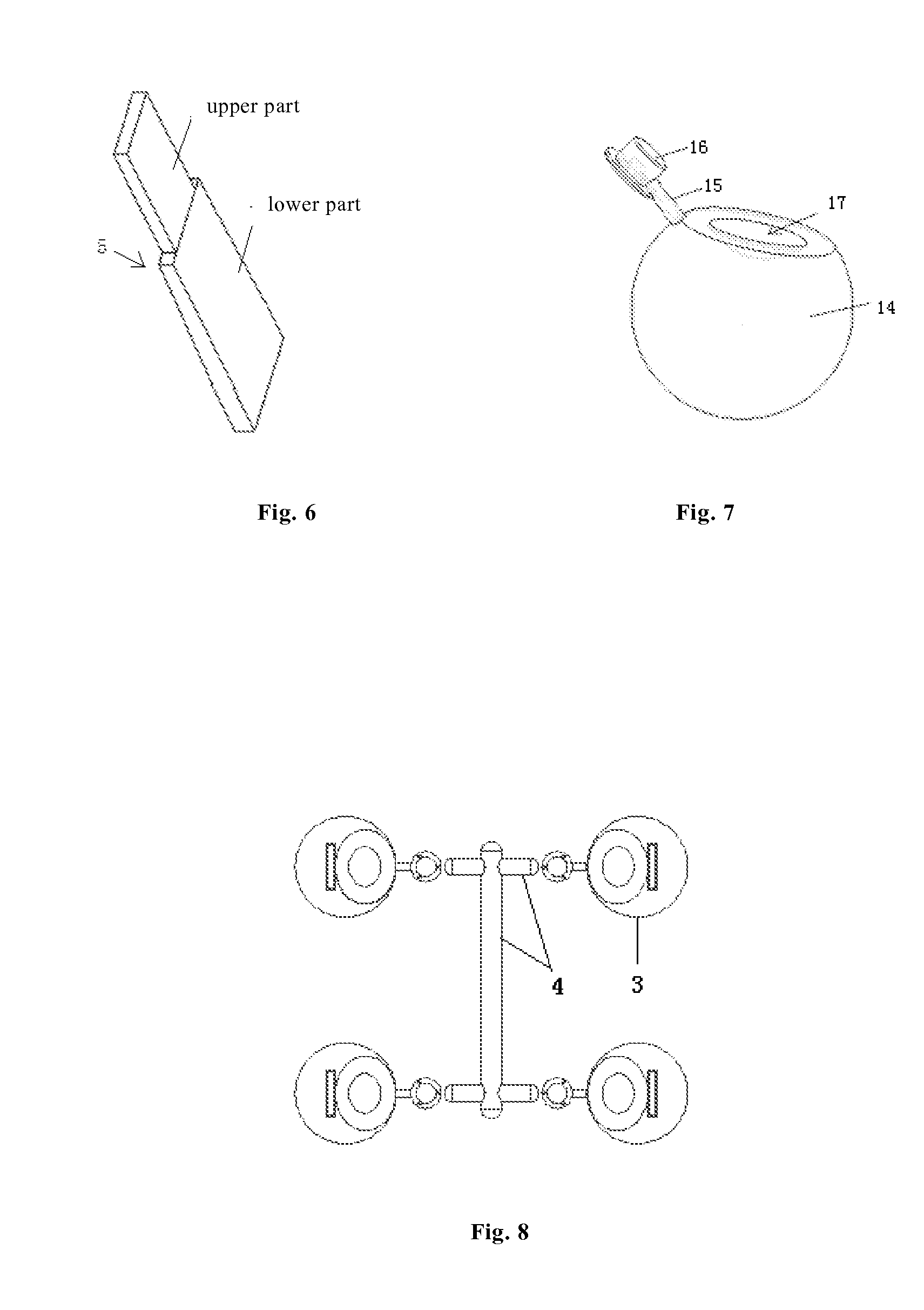

[0051]Referring to FIGS. 1-4, the mold in this embodiment comprises the upper mould 1, the lower mould 2, and the core 3. The core 3 which is connected with the drainage tube pin10, is set between the upper mould1 and the lower mould2, the drainage tube pin10 is connected with plastic injection channel4). Heating holes 6 are provided on the upper mould1 and the lower mould 2.

[0052]The upper mould1 has a slide block7, and the core3 is connected with the positioning plate5 which located in the slide block7. The drainage tube pin10 is connected with the plastic injection channel4 via the drainage valve13.

[0053]Referring to FIGS. 5 and 6, the core3 is connected with the positioning plate5 which includes an upper part and a lower part, and the upper part is fixed in the slide block7.

[0054]The drainage tube pin 10 is connected with the plastic injection channel4 via the drain valve13, the drain valve has a piece of rigid sheet which is positioned by the located pin9. An aluminum sheet 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chord length | aaaaa | aaaaa |

| chord length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com