Air-driven hydraulic pump with pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

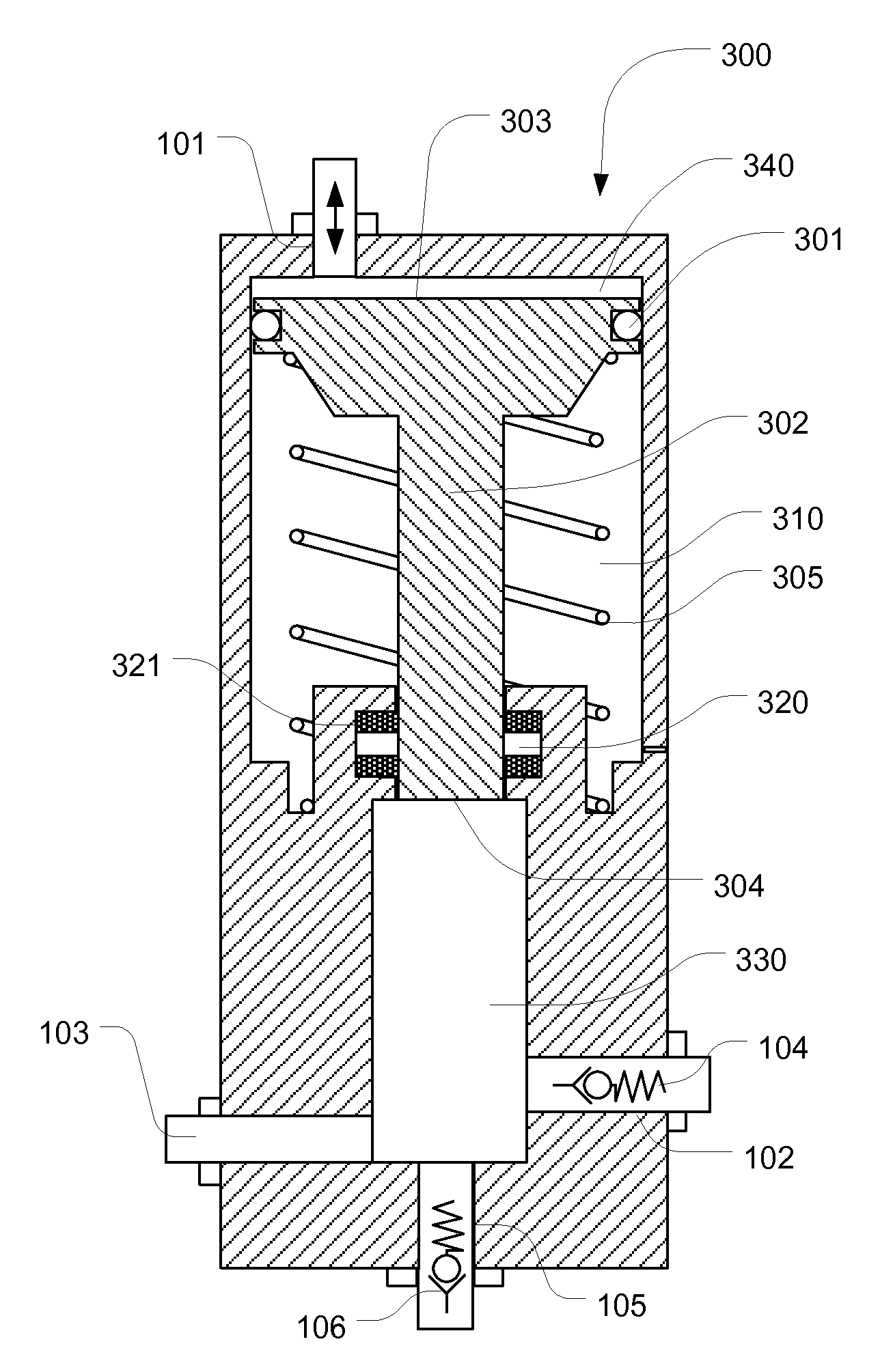

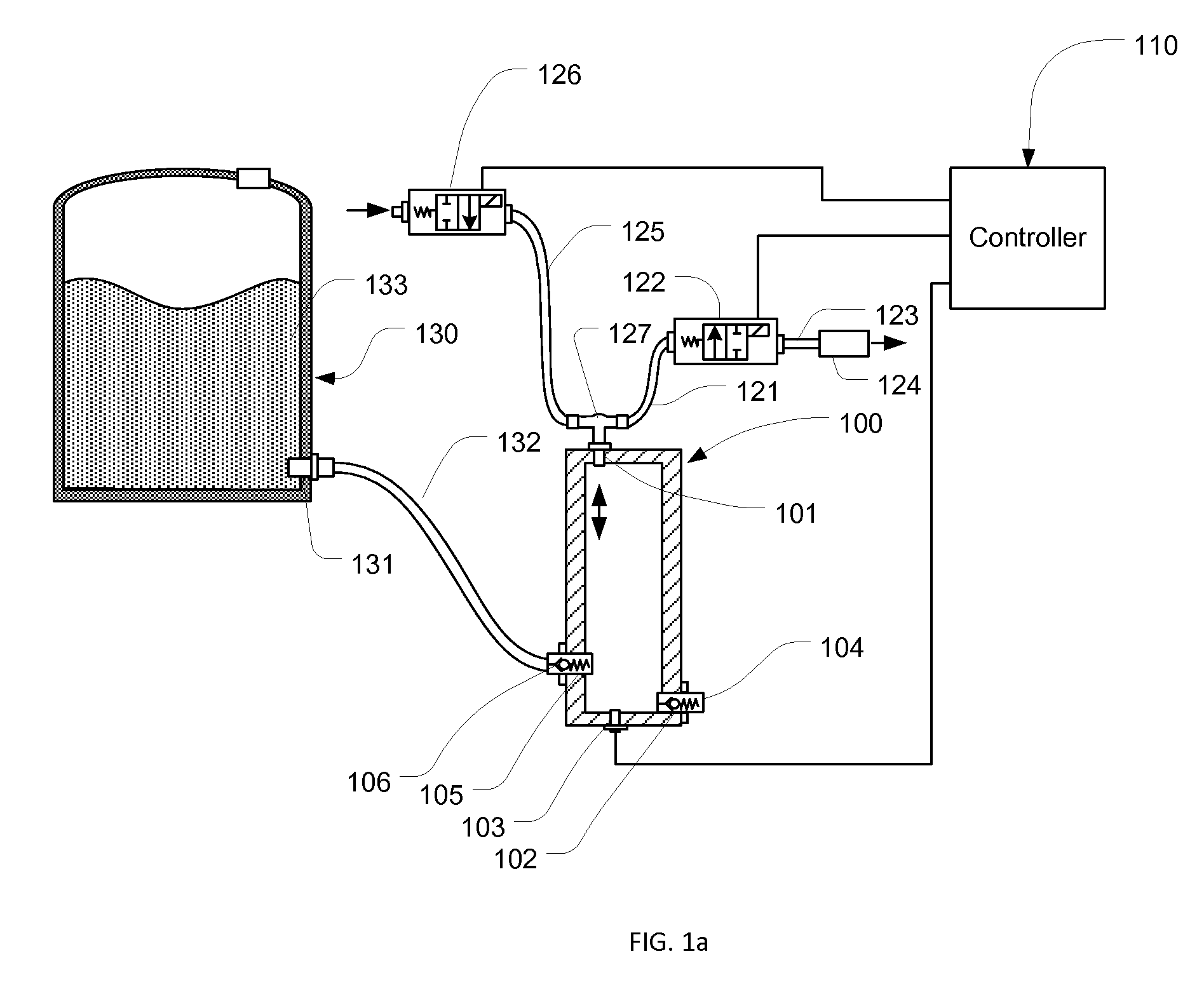

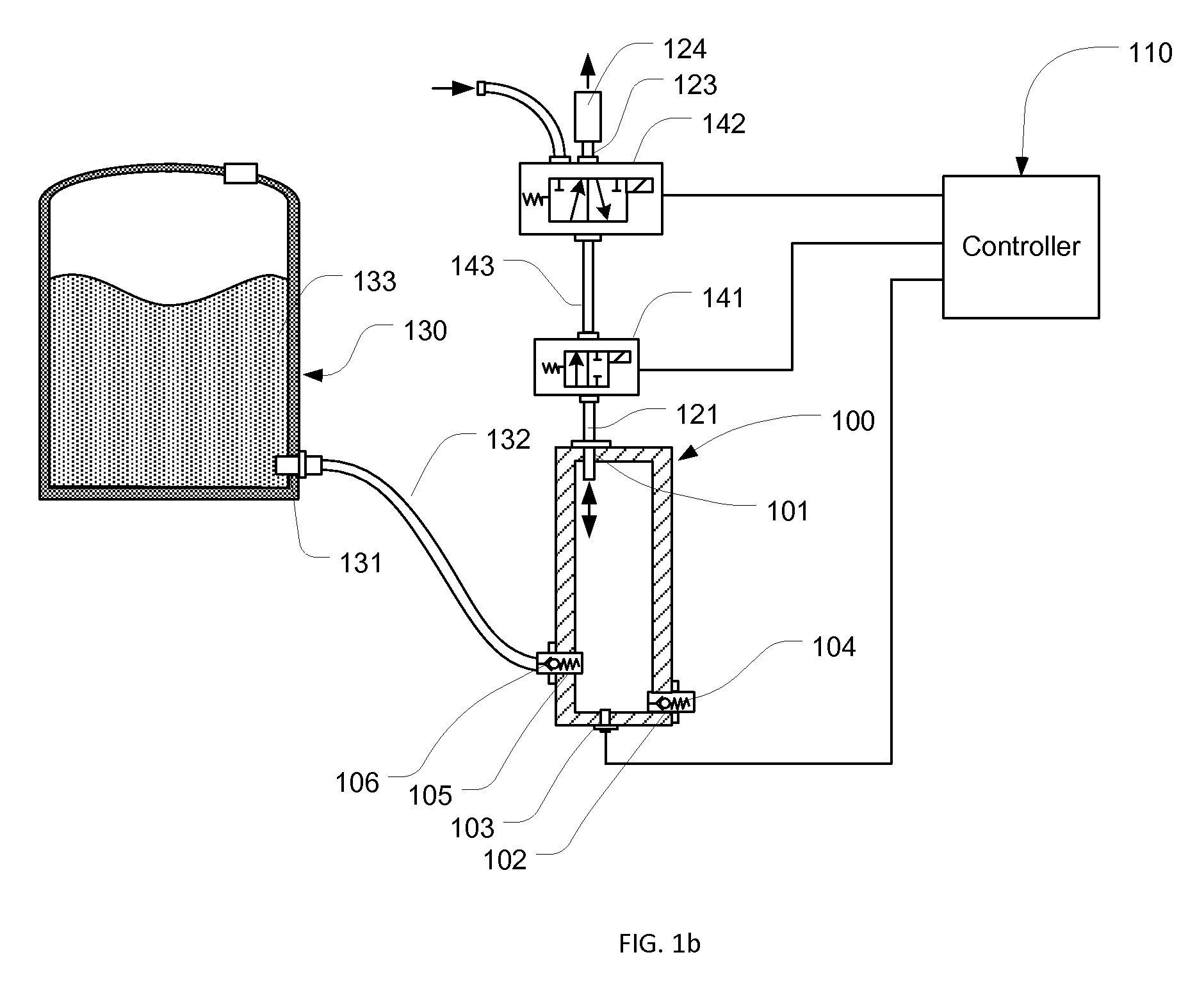

[0023]Referring to FIG. 1a, a pump 100 includes a gas port 101, a liquid inlet port 105, a liquid outlet port 102, and a pressure sensor 103. Through a liquid passage 132, the liquid inlet port 105 is fluidly connected to a port 131 of a liquid tank 130, which contains a fluid 133. Inside the inlet port 105, a check valve 106 only allows liquid to flow from the liquid tank 130 to the pump 100. Fluid in the pump 100 flows out through the liquid outlet port 102, which has a check valve 104 included, while pressure inside the pump is measured by the pressure sensor 103 and the sensing value is sent to a controller 110. The gas port 101 of the pump 100 is fluidly coupled to the outlet of a two-way solenoid valve 126 through a Tee connector 127 and an air passage 125, and the inlet of the solenoid valve 126 is connected to a compressed air supply (not shown in FIG. 1a). The Tee connector 127 is also fluidly connected to the inlet of another two way solenoid valve 122 through an air passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com