Pressure relief system for footwear

a pressure relief system and footwear technology, applied in the field of footwear pressure relief system, can solve the problems of consumers having a hard time understanding precisely what comfort means, and no universal standard for comfort, etc., and achieve the effects of reducing pressure, improving pressure re-distribution, and increasing conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

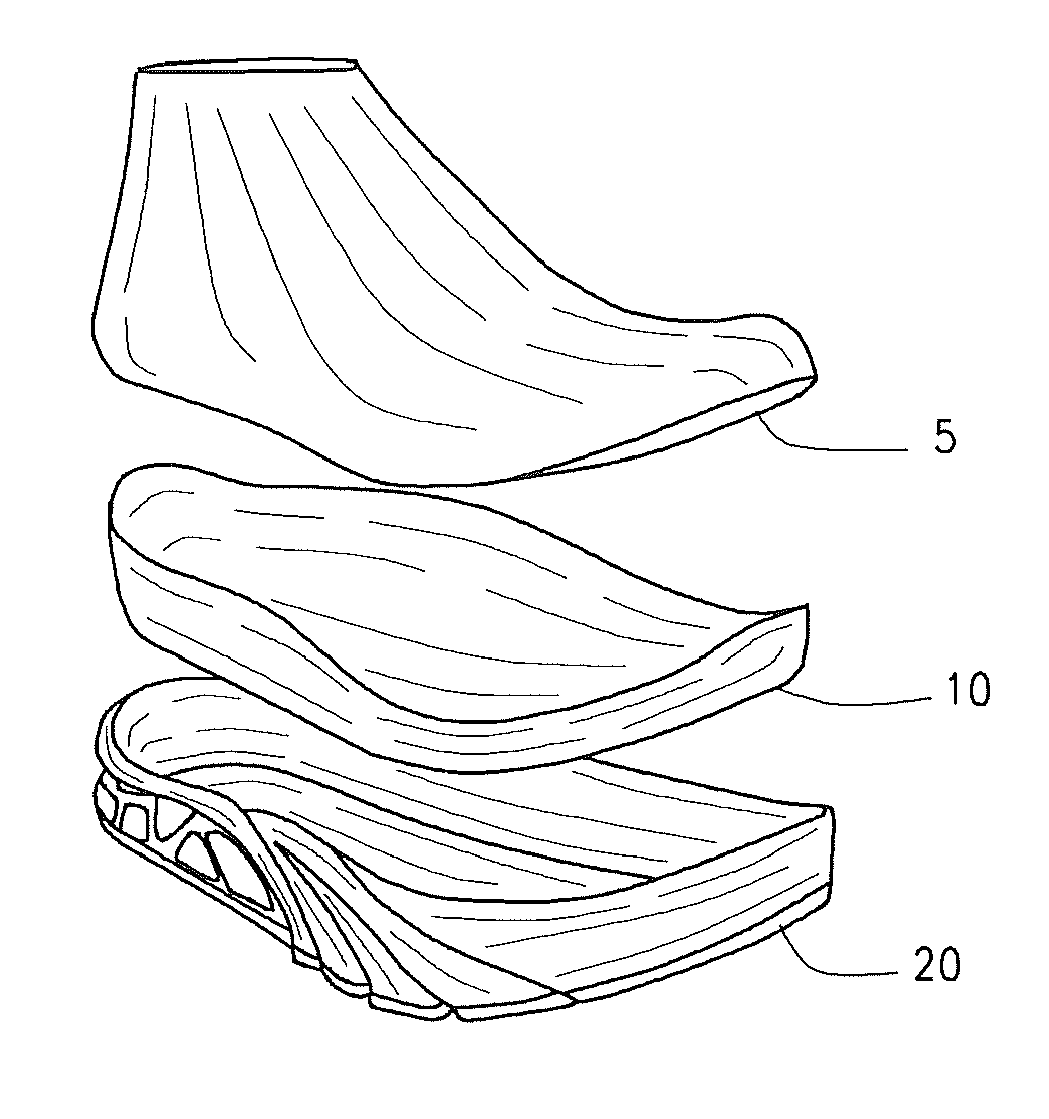

[0028]In the present invention, a sock liner is provided which improves comfort and can be built into any type of shoe. As shown in FIG. 1, a shoe will include an upper or last 5, the sock liner 10 and the midsole / outsole 20 (“outsole”). Outsole 20 is positioned on the underside of the shoe for engagement with a walking surface such as the ground, sidewalk, floor or other supporting surface. Preferably, the top surface of the outsole is shaped to conform to the bottom surface of the sock liner 10. The thickness of outsole 20 may be less than conventional shoes in order to compensate for the added thickness of the sock liner 10. The outsole 20 may be constructed of any suitable material for example, leather, elastomer, polymer, a composite thereof or the like depending upon the type of shoe desired. The sock liner 10 and outsole 20 may be secured to one another using any suitable attachment means including cement, adhesives, glue, welt and direct attachment constructions

[0029]For eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com