Combined miscible or near miscible gas and asp flooding for enhanced oil recovery

a technology of enhanced oil recovery and gas, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of reducing the sweep efficiency, the macroscopic sweep efficiency is relatively poor, and the contact and first contact miscibility, so as to improve the sweep efficiency and enhance the oil recovery. , the effect of high micro/macro scal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

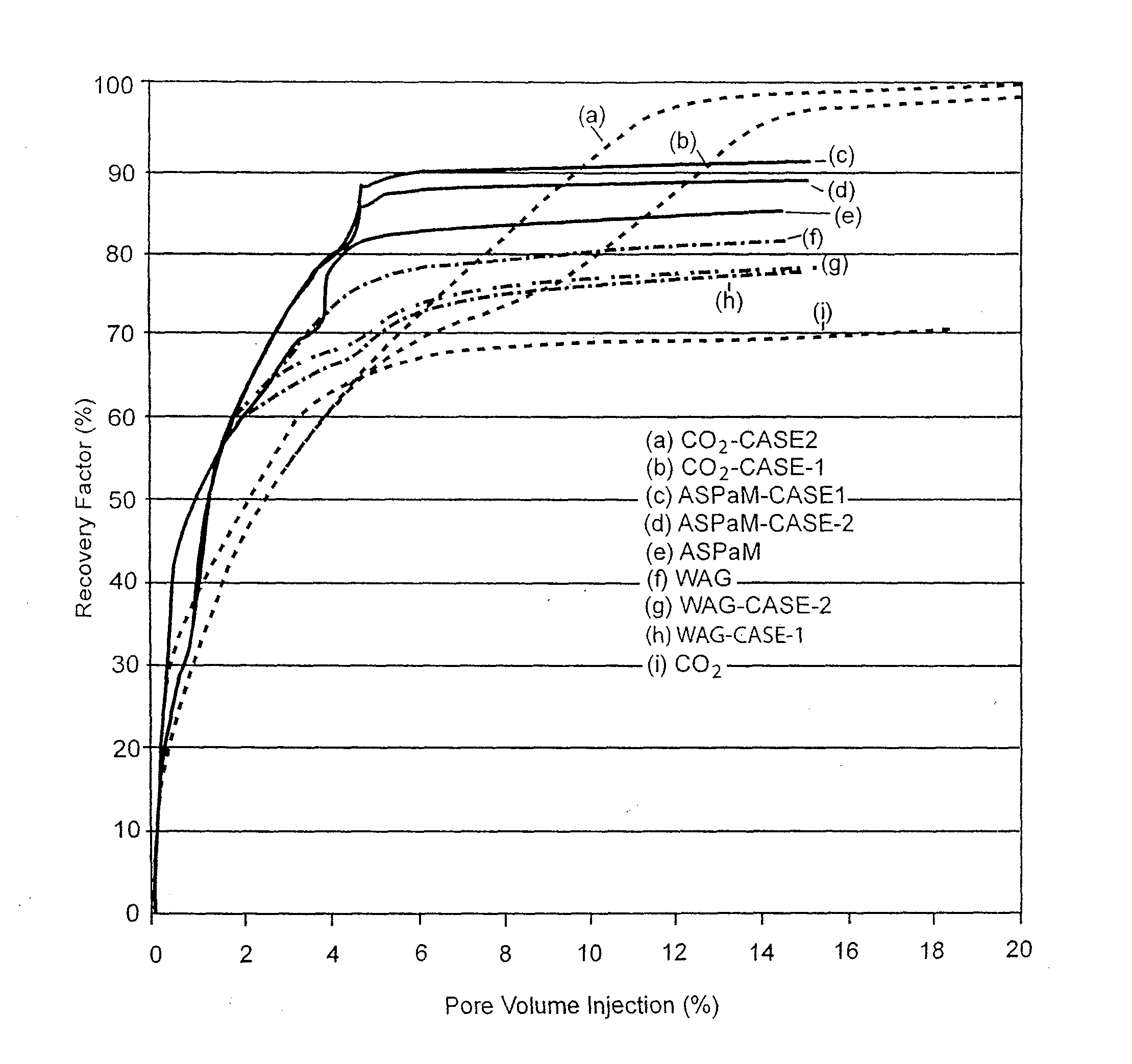

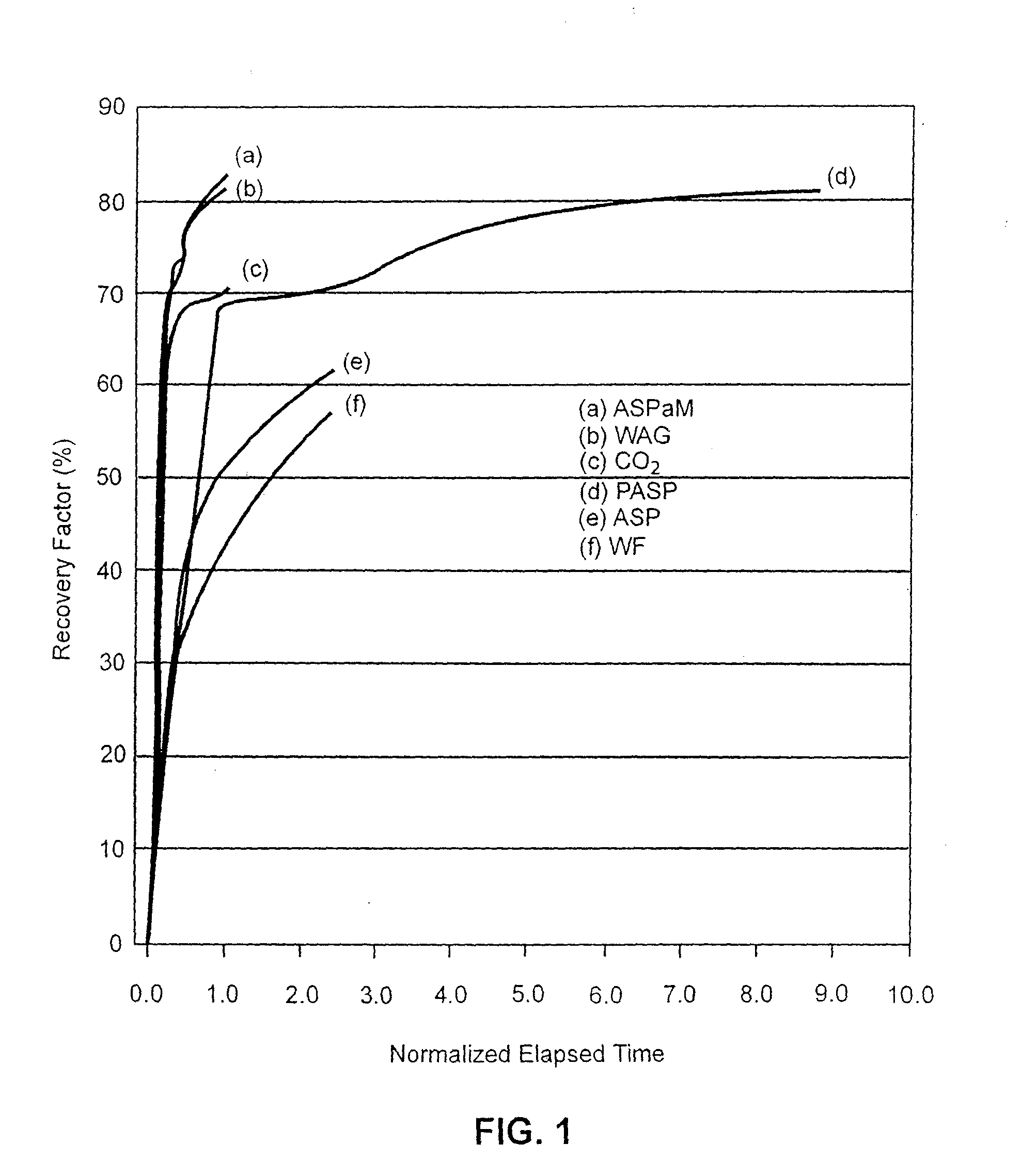

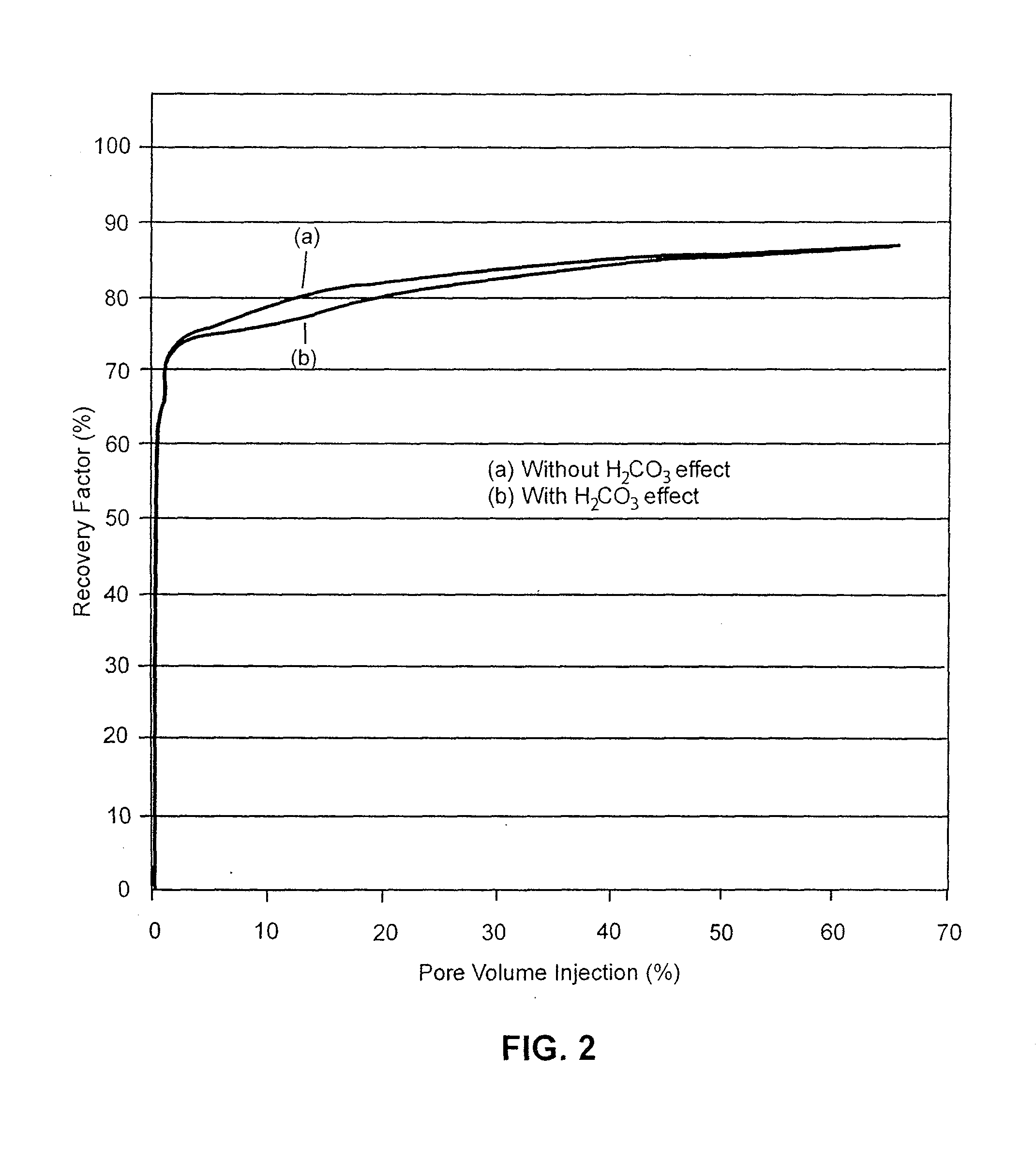

[0032]Briefly, the present invention includes a method of enhanced oil recovery that combines a miscible or near miscible gas flooding with a waterflood enhanced with slugs of alkali, surfactant and polymer. Miscible gases may include carbon dioxide, ethane, propane, butane and mixtures thereof, as examples. The term “near miscible” as used herein relates to situations where the gas flood occurs at pressures slightly below the miscible pressure, and the oil recovery from these processes is still high. As stated hereinabove, WAG injection improves gas injection sweeps, principally by using the water to control the mobility of the displacement, and to stabilize the front. Because the microscopic displacement of the oil by gas is normally better than that using water, the WAG injection combines the improved displacement efficiency of gas flooding with an improved macroscopic sweep by water injection. ASP flooding produces the lowest interfacial tension and highest displacing fluid visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com