Symmetrical series fan structure

a fan structure and fan technology, applied in the direction of machines/engines, positive displacement liquid engines, machines/engines, etc., can solve the problems of high heat generation of compact ic chips such as cpu or graphics chips, increasing mold development cost and manufacturing cost, etc., to save mold development cost, reduce manufacturing cost, and save mold development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

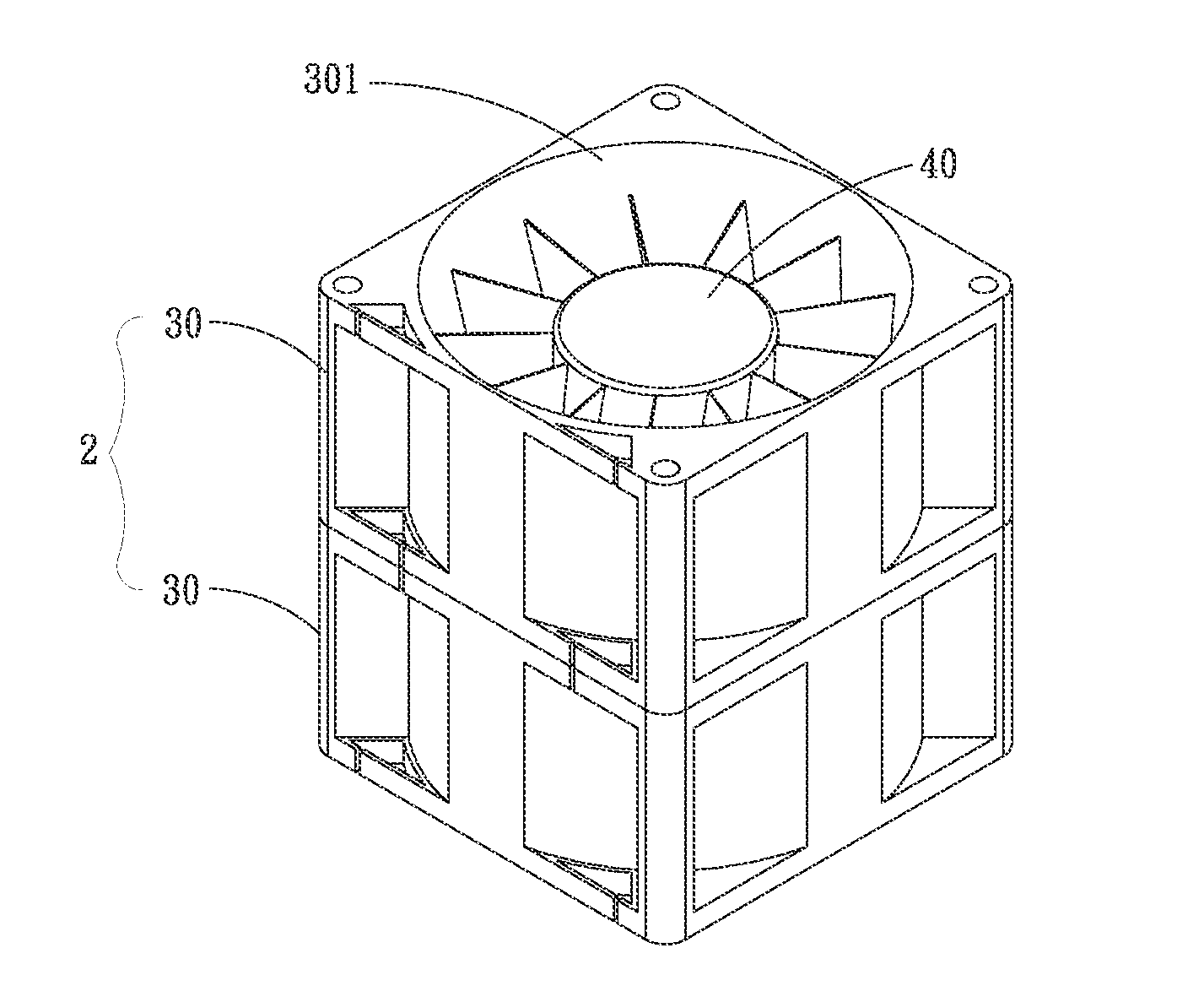

[0024]Please refer to FIGS. 2 and 3. FIG. 2 is a perspective exploded view of a first embodiment of the symmetrical series fan structure of the present invention. FIG. 3 is a perspective assembled view of the first embodiment of the symmetrical series fan structure of the present invention. The symmetrical series fan structure 2 includes multiple frame bodies 30. In this embodiment, the symmetrical series fan structure 2 includes two frame bodies 30, which are serially connected and assembled with each other. Each frame body 30 has a first through hole 301, a second through hole 302 and a base 303. The first and second through holes 301, 302 are respectively formed on two sides of the frame body 30. A flow way 304 is formed between the first and second through holes 301, 302. Multiple connection members 3031 extend from a circumference of the base 303 in straight form. The base 303 is positioned in the second through hole 302 and connected to the frame body 30 via the connection mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com