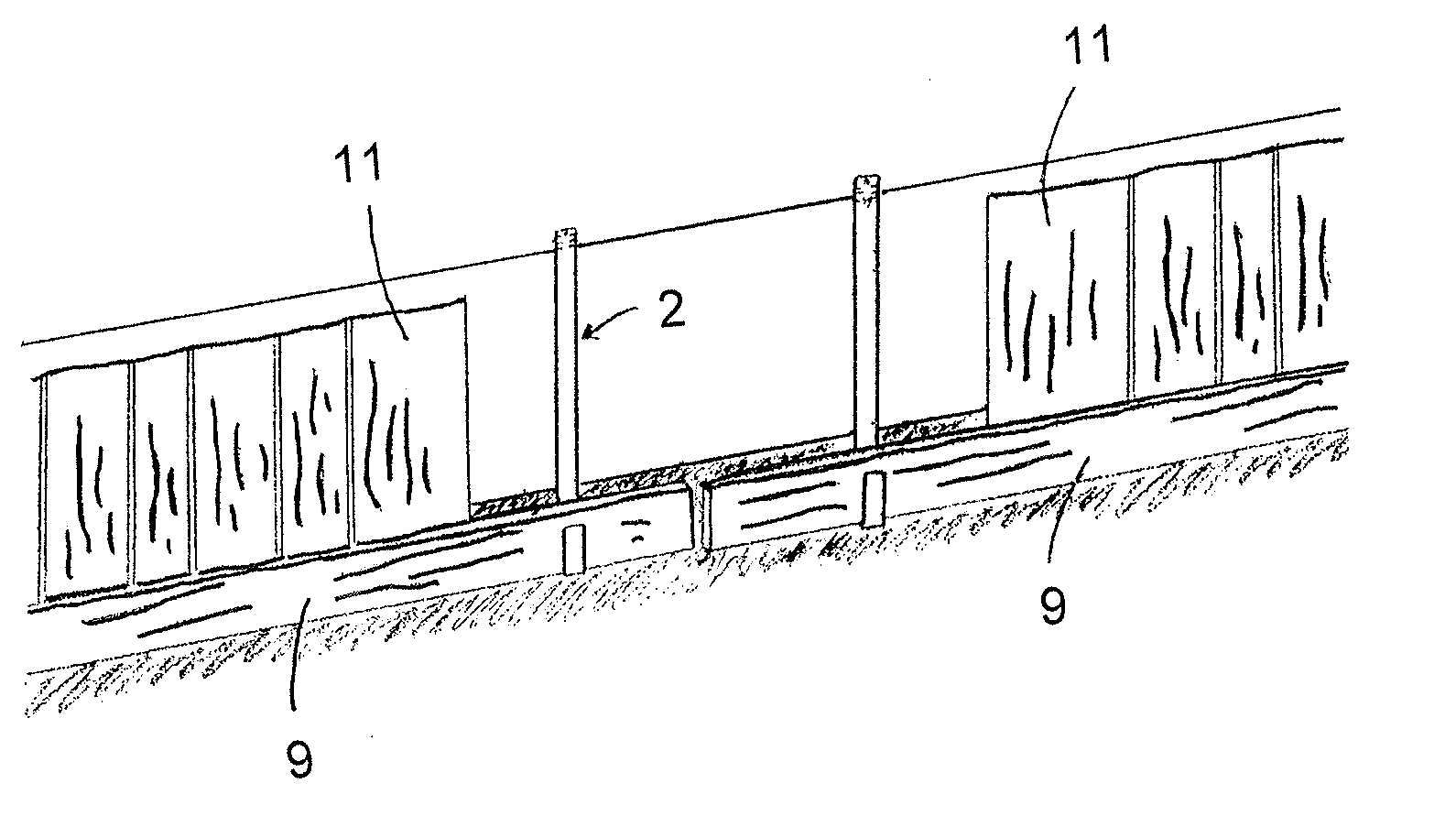

Starter jig

a jig and starter technology, applied in the field of new wood and composite shake or shingle jigs, can solve the problemsavoiding the use of tools, and wasting time, and achieving the effects of reducing the overall installation time, and being easy to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

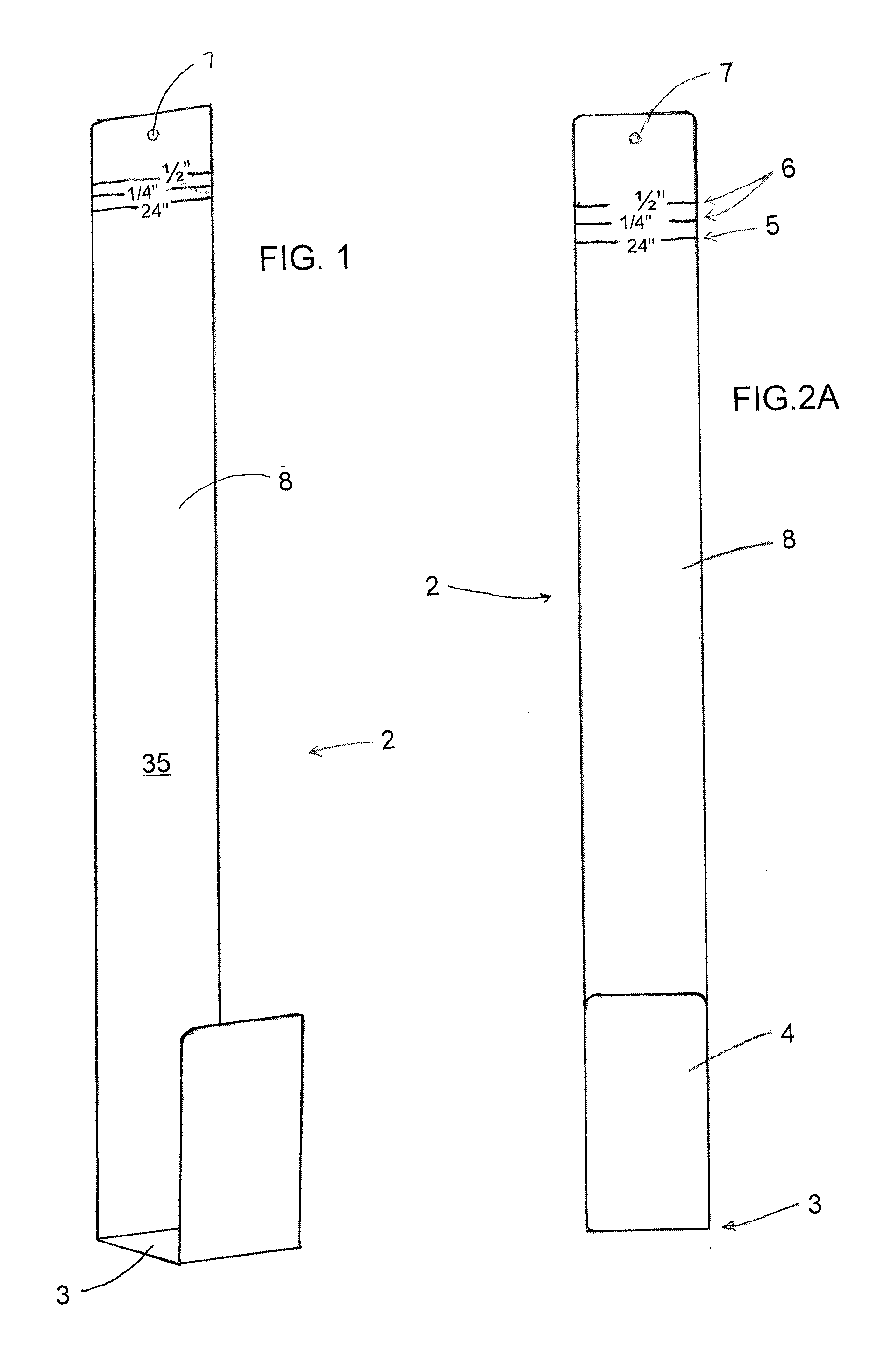

first embodiment

[0047]A slight variation of the shake starter jig 2 is shown in FIG. 2B and this variation also includes an anchor leg 8 which has an upper section that includes both the main position indicator 5 as well as a pair of adjustment markers 6 which form a pair of adjusted positions for the shake starter jig 2. According to this embodiment, the main position indicator 5 and the pair of adjustment markers 6 are generally used for the same purposes discussed above. Since this variation is quite similar to the first embodiment, only the difference between this variation and the previous embodiment will be discussed in detail.

[0048]As shown in FIG. 2B, instead of having a single circular anchor hole 7, the anchor hole comprises an aperture 30 having three cup shaped jig supports 31, 32, 33 for supporting the starter jig 2 at a different distance from the bottom of the ledger shelf 3. The lowermost jig support 31 is associated with the main position indicator and is located a desired distance...

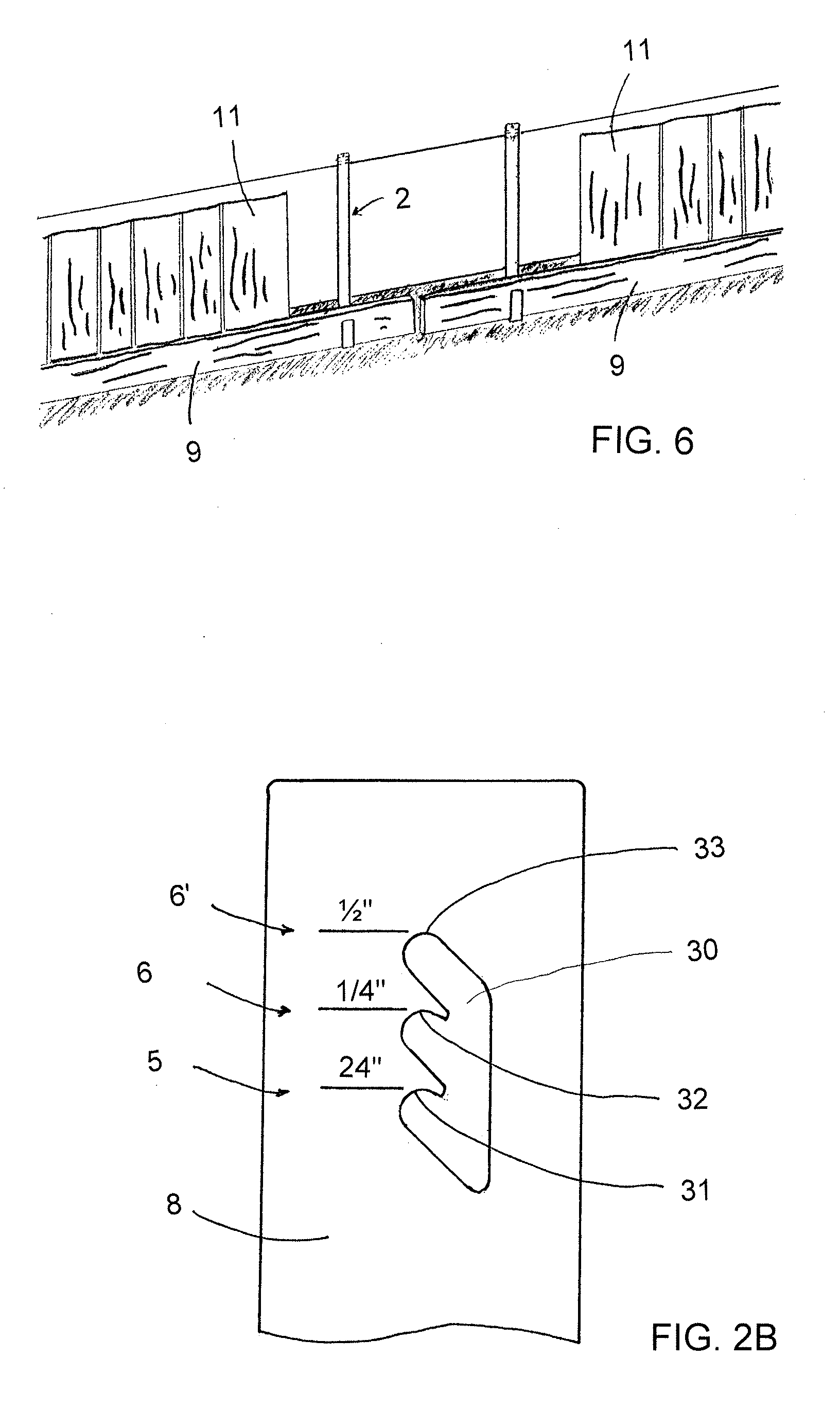

second embodiment

[0052]One difference with respect to the anchor leg 8 is that the anchor leg 8, comprises three sections, namely, the first section 8′ which supports the main position indicator 5 and the first and second adjustment markers 6, a second section 8″ which is integral with the ledger shelf 3, and an intermediate section 8″ which couples were interconnects the first section 8′ with the second section 8″. As can be seen in FIGS. 7 and 8, the intermediate section 8″ forms an angle of between approximately 100 and 135 degrees, more preferably an angle of about 115° or so, with the front surface 35 of the first section 8′, while the intermediate section 8″ forms an angle of between approximately 100 and 135 degrees, more preferably an angle of about 115° or so, with the second section 8′″ of the anchor leg 8 to thereby form a stepped out section 18 for the shake starter jig 2, the purpose of which will be become readily apparent in view of the following description.

[0053]A suspension mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com